Telescopic sleeve pipe

A telescopic sleeve and jacket technology, which is used in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of insufficient adjustment and complicated processing of pipe materials, achieve simple and durable structure, facilitate the overall shape design, and improve the overall shape. Effects and Values of Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

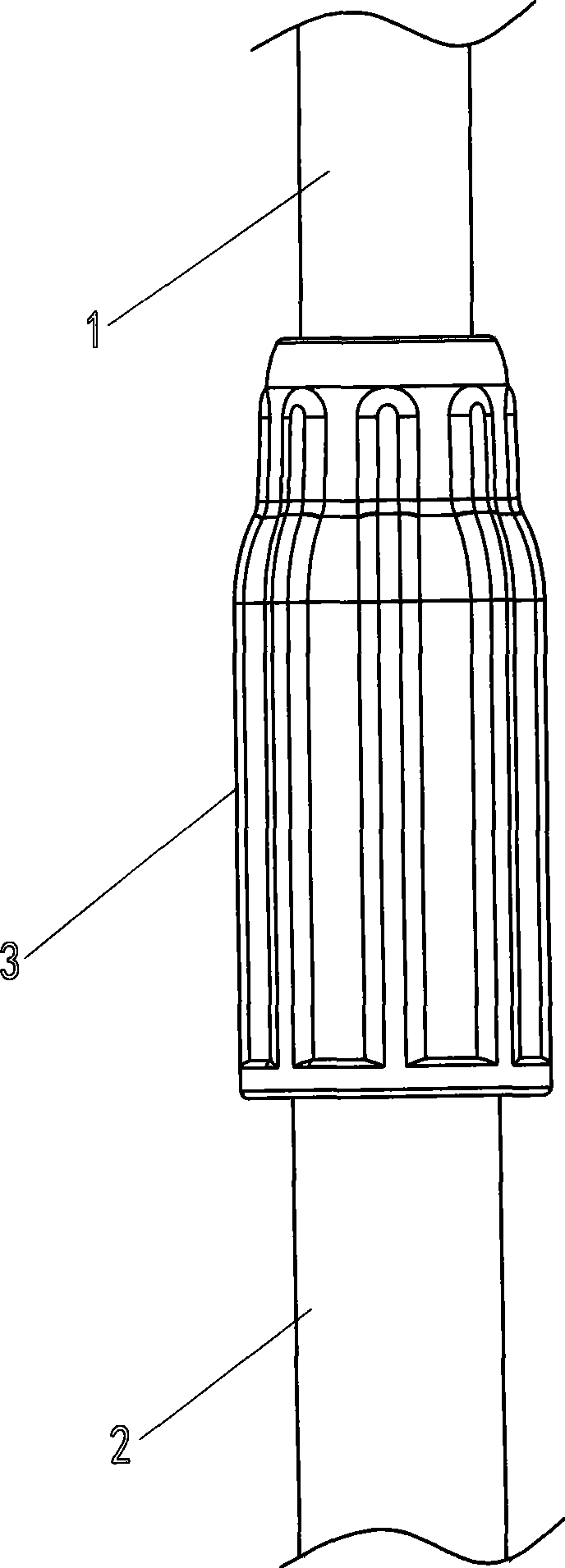

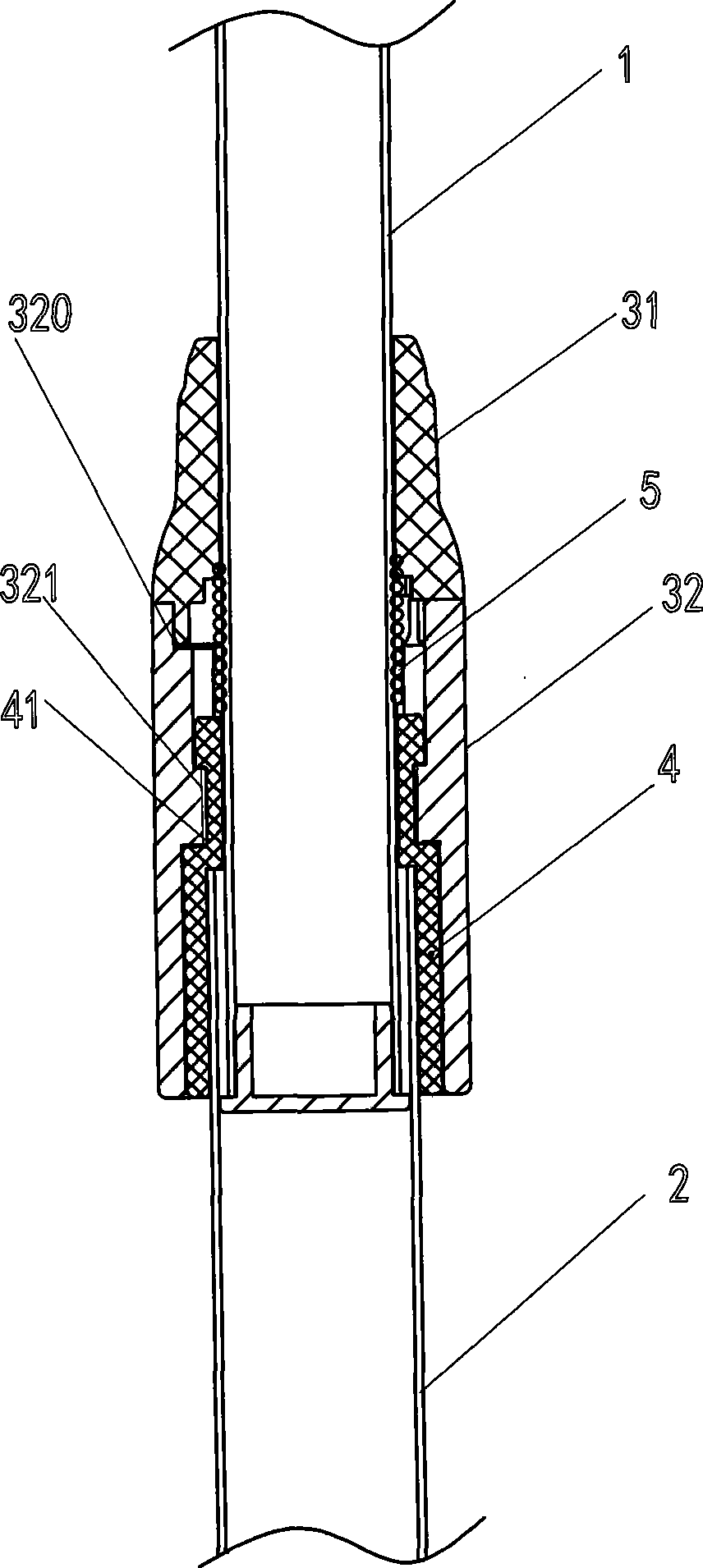

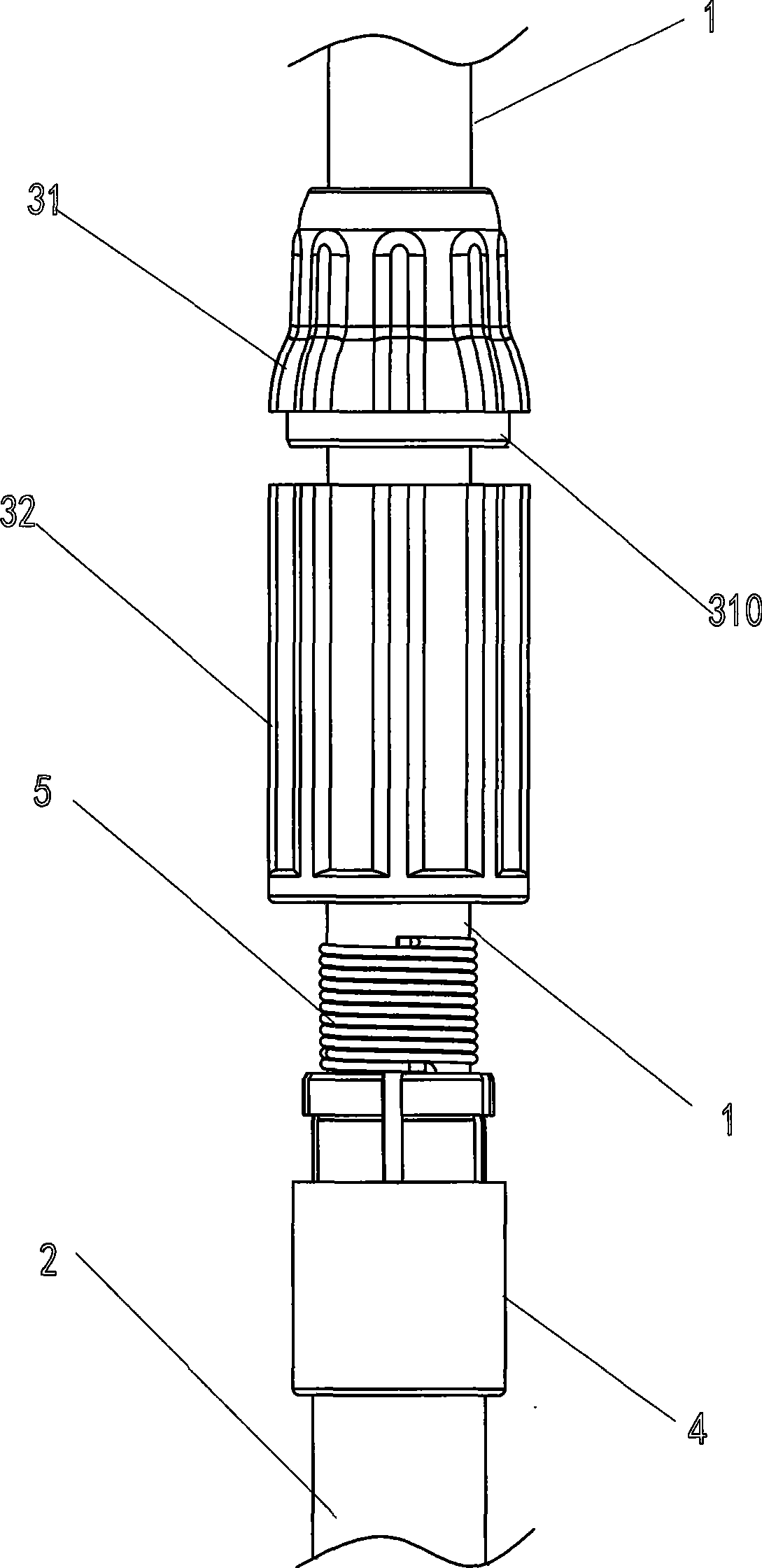

[0018] see Figure 1~3 , a telescopic sleeve, mainly composed of an outer tube 2, an inner tube 1 partially sleeved in the outer tube, and an adjustment piece sleeved at the junction of the outer tube and the inner tube. Slightly rotating the adjustment part can quickly make the inner tube 1 protrude from the outer tube 2 or retract into the outer tube, and correspondingly make the entire tube lengthen or shorten. Turning the jacket overcomes the spring force to make the inner tube stretch. The new position is quickly positioned due to the restoring force of the adjusting spring. The telescopic pipe can be used as a telescopic support frame for musical instruments, and the telescopic support frame is convenient for storage and transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com