Conductive material for a connecting part

A technology of conductive materials and connecting parts, which is applied in the direction of contact parts, contact parts manufacturing, application, etc., can solve the problems of low contact resistance, low insertion force, micro-sliding wear, etc., achieve high-efficiency assembly operations, suppress friction coefficient, and good The effect of brazeability

Active Publication Date: 2011-05-11

KOBE STEEL LTD

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Furthermore, the insertion force of the terminal with the Cu-Sn alloy coating layer formed on the surface is further reduced

On the other hand, if the thickness of the Sn cladding layer is reduced, there is a problem of increasing the contact resistance of the terminal when it is kept for a long time in a high-temperature environment as high as 150°C such as an engine room of an automobile.

In addition, if the thickness of the Sn cladding layer is thin, the corrosion resistance and solderability will also be reduced.

In addition, the Sn cladding layer is also prone to micro-sliding wear

In this way, it is not yet possible to obtain low insertion force in a fully formed form, and after repeated insertion and extraction, it can still maintain low contact resistance in a high temperature environment for a long time, in a corrosive environment or in a vibration environment, and at the same time brazeability Excellent characteristics required for conductive materials such as connecting parts, so further improvement is required

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0077] The following examples focus on the main points and describe more specifically, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

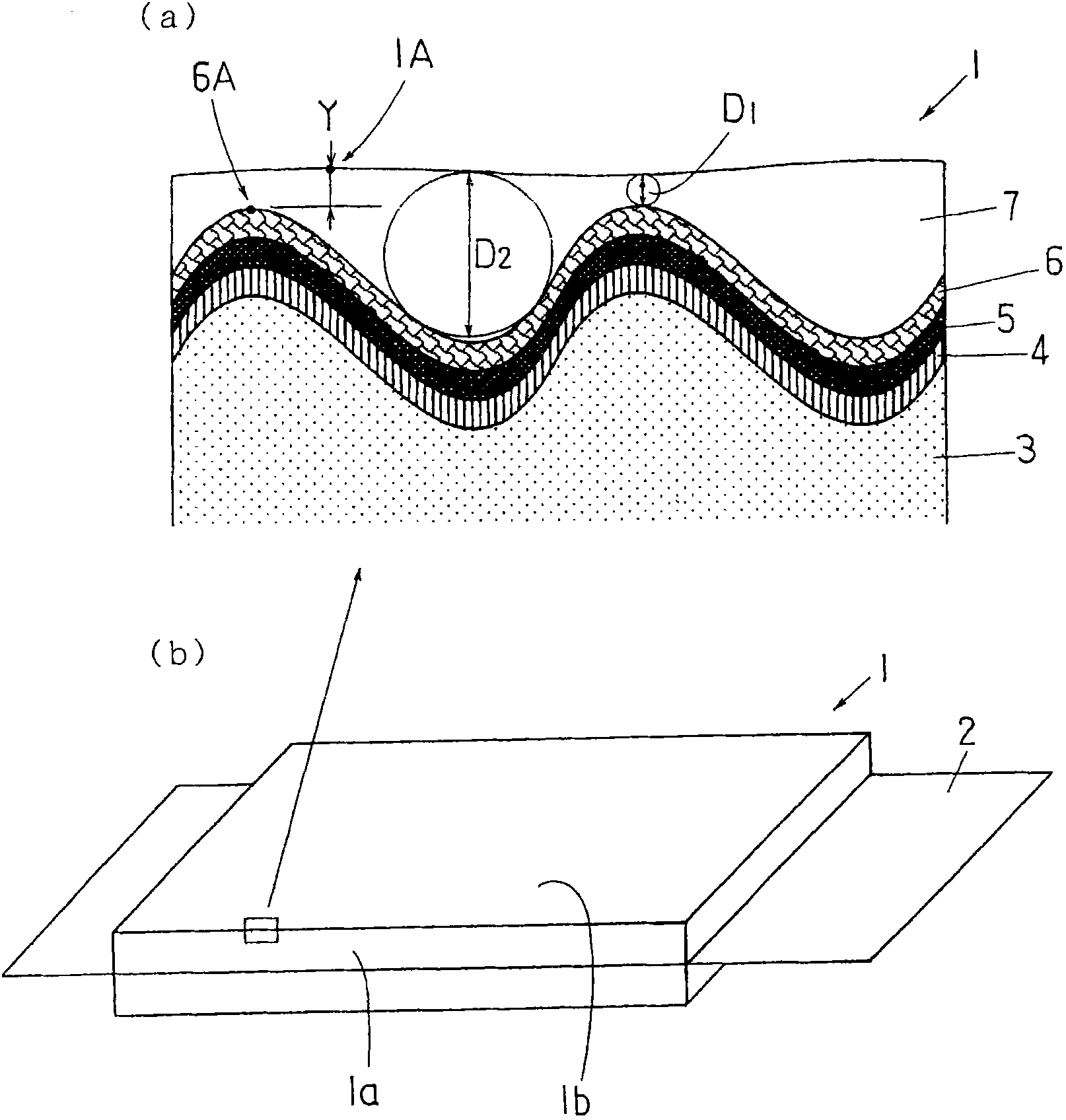

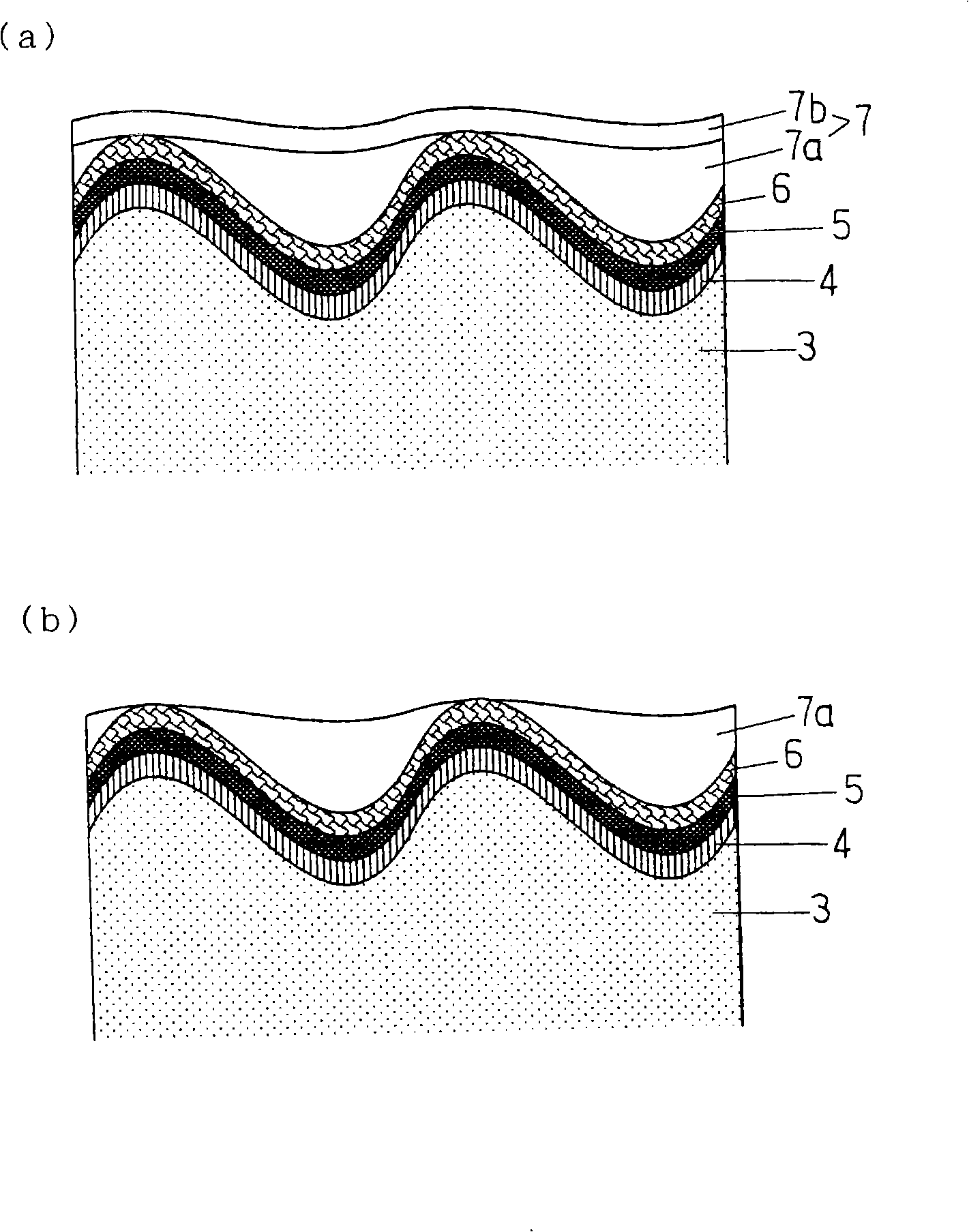

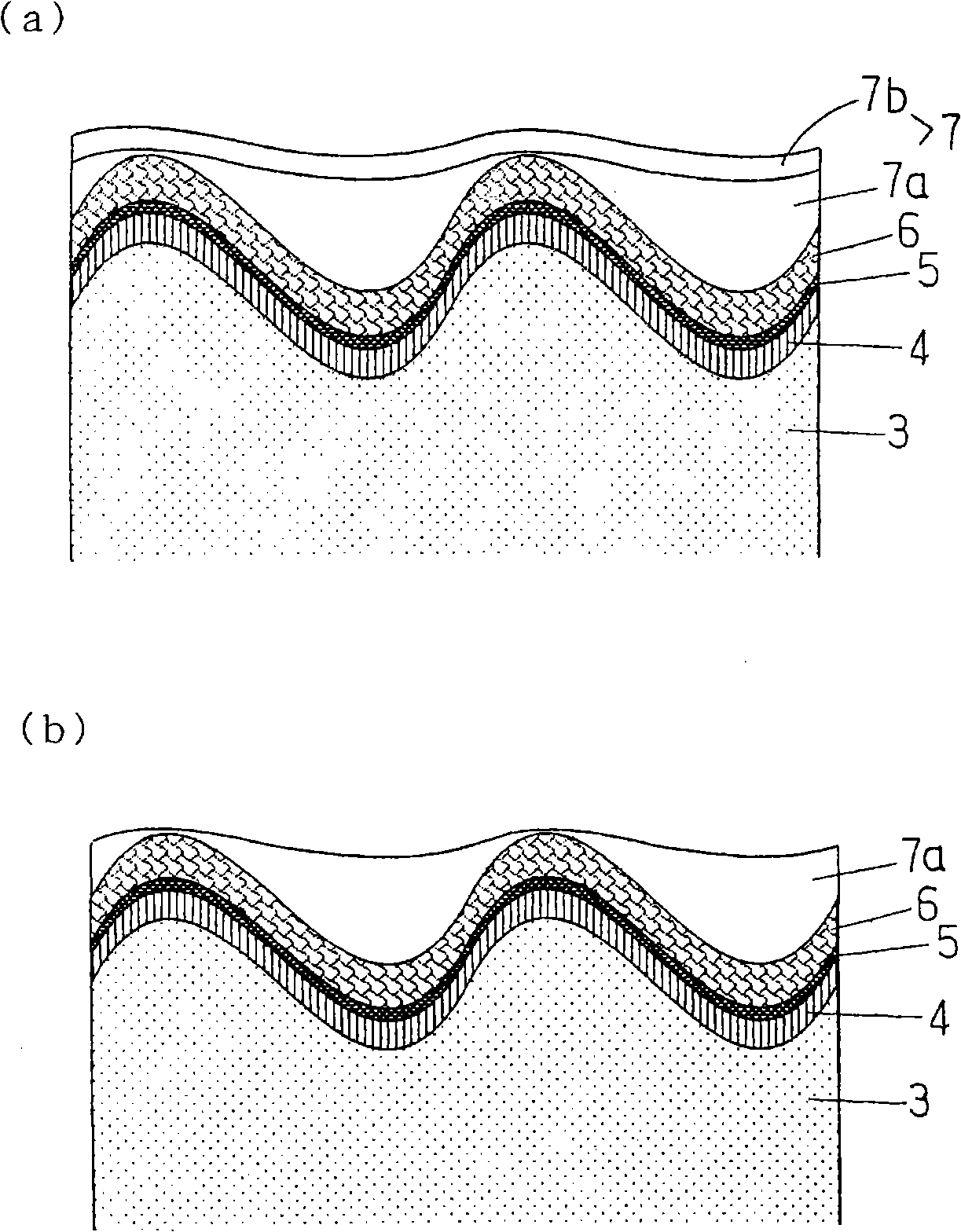

The invention provides a conductive material (1) for a connecting part, on the roughened surface, including: a base material made up of a Cu strip; a Ni covering layer having an average thickness of 0 to 3.0 microns, a Cu covering layer having an average thickness of 0 to 1.0 microns, and a Sn covering layer according to the above sequences. On the vertical section of the surface (1b) relative tothe material (1), the diameter (D1) of the minimum inscribed circle of the Sn covering layer is less than 0.2 microns, the diameter (D2) of the maximum inscribed circle is 1.0 to 20 microns, and the difference in elevation [y] between the outermost point of the material and the outermost point of the Cu-Sn alloy covering layer is less than 0.2 microns. A bright or semi-bright Sn electroplating layer having an average thickness is formed on the outermost layer as part of the Sn covering layer. According to the formation, a conductive material for a connecting part can be obtained, which has a low friction coefficient (low insertion force), can maintain reliability of electrical connection (low constriction resistance) and meanwhile can ensure solderability.

Description

technical field [0001] The present invention relates to a conductive material for connecting parts such as terminals and buses mainly used in electrical wiring of automobiles and consumer equipment, and more particularly relates to a conductive material that can reduce friction and loss during fitting and can be used in severe use environments. Conductive material for connecting parts that has both electrical connection reliability and soldering reliability. Background technique [0002] In terms of conductive materials for connecting parts such as terminals and buses used in electrical wiring such as automobiles and consumer equipment, in addition to the case of important circuits that require high electrical connection reliability for low-level signal voltages and currents, Cu or Cu alloy subjected to Sn plating (including Sn alloy plating such as brazing plating) is used. Although Sn plating is widely used due to its low cost compared with Au plating and other surface tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01R13/03H01R43/16

CPCB32B15/01Y10S428/929Y10T428/1291Y10T428/12715Y10T428/12722C25D5/10C25D5/627C25D7/00C25D5/12C25D5/505C25D5/34H01R13/03

Inventor 真砂靖尾崎良一坂本浩杉下幸男

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com