Cut die feeding mechanism

A feeding mechanism and blanking die technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of coil material affecting the accurate feeding of coil material and hindering the slippage of waste material, so as to achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

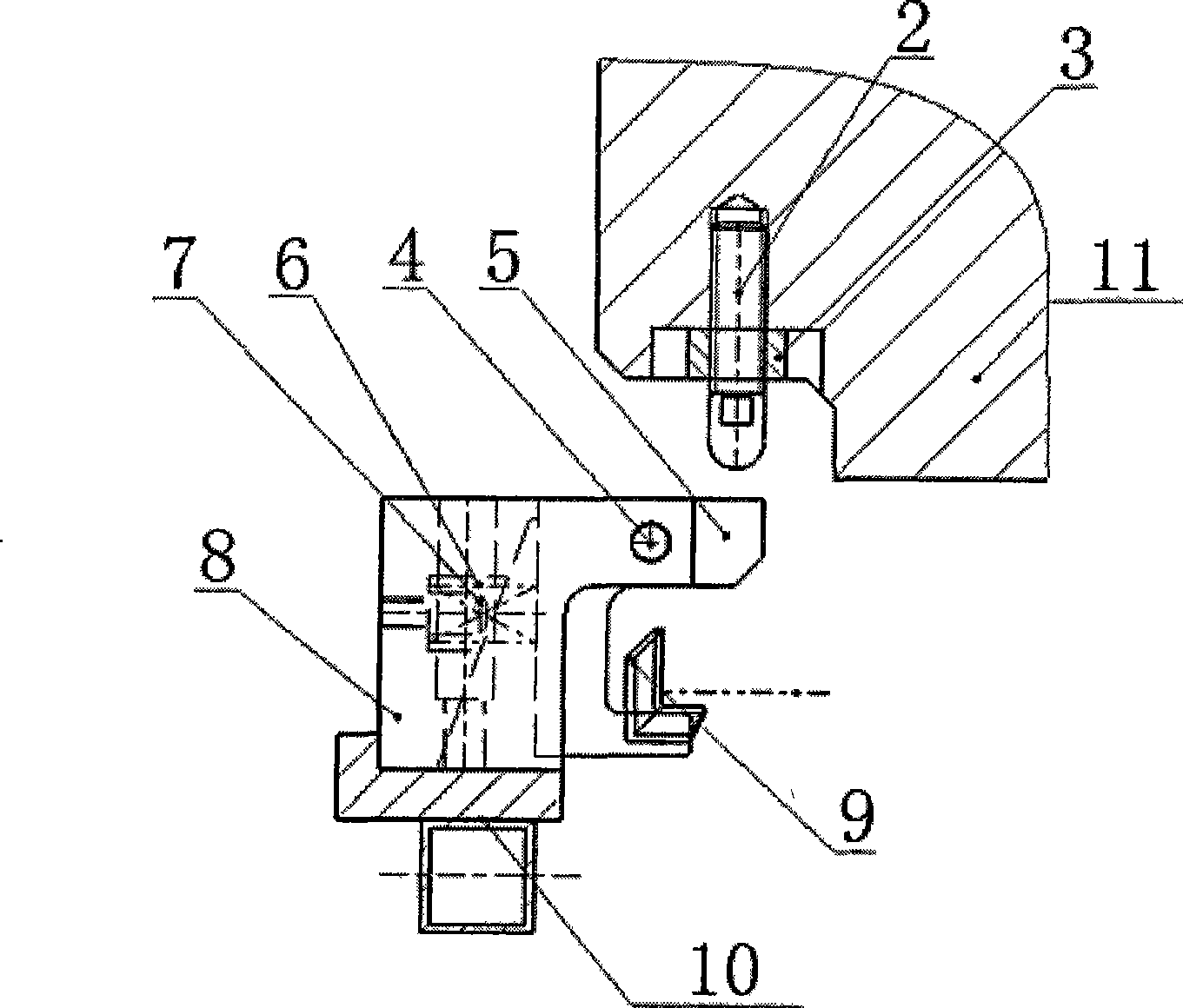

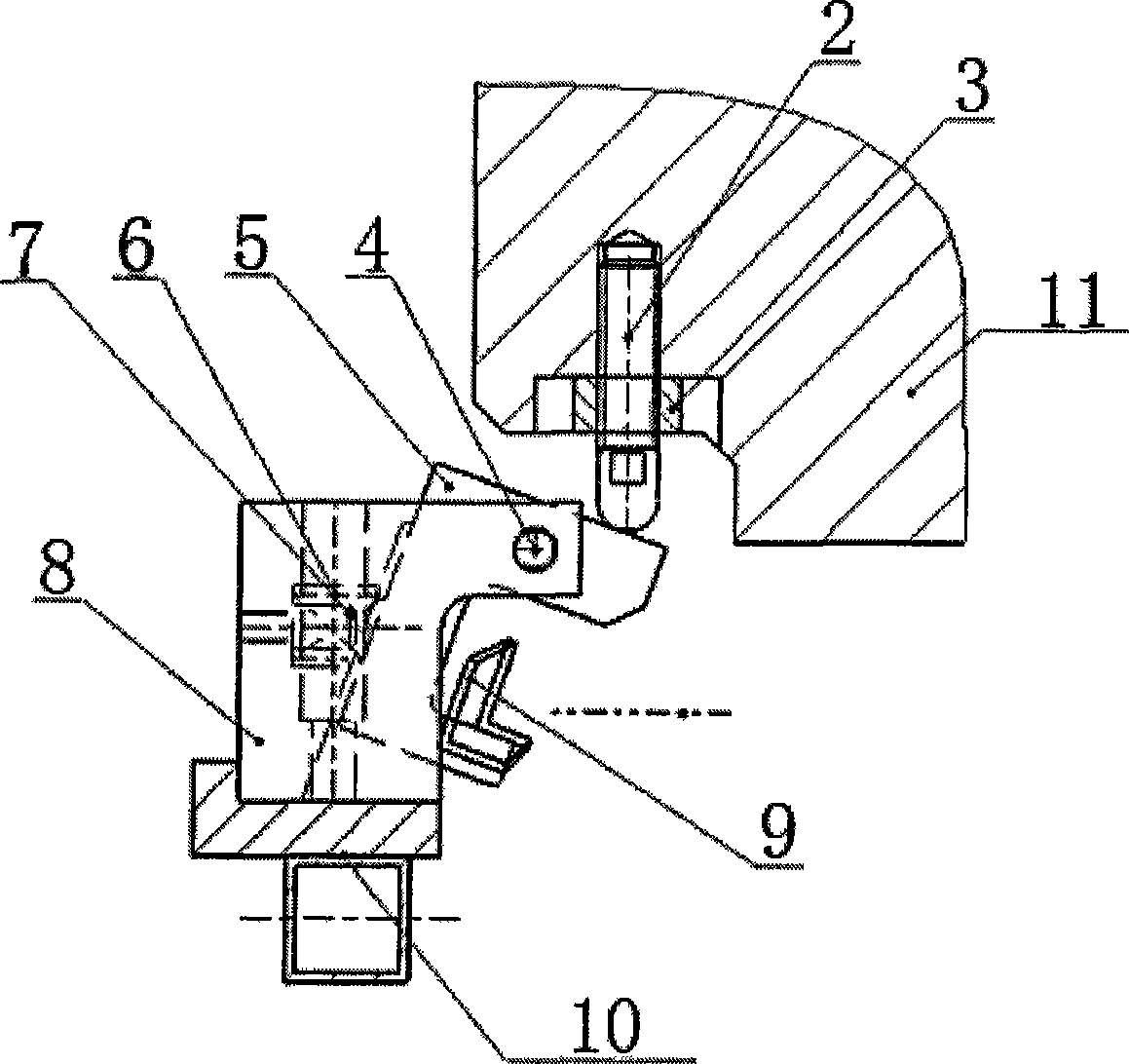

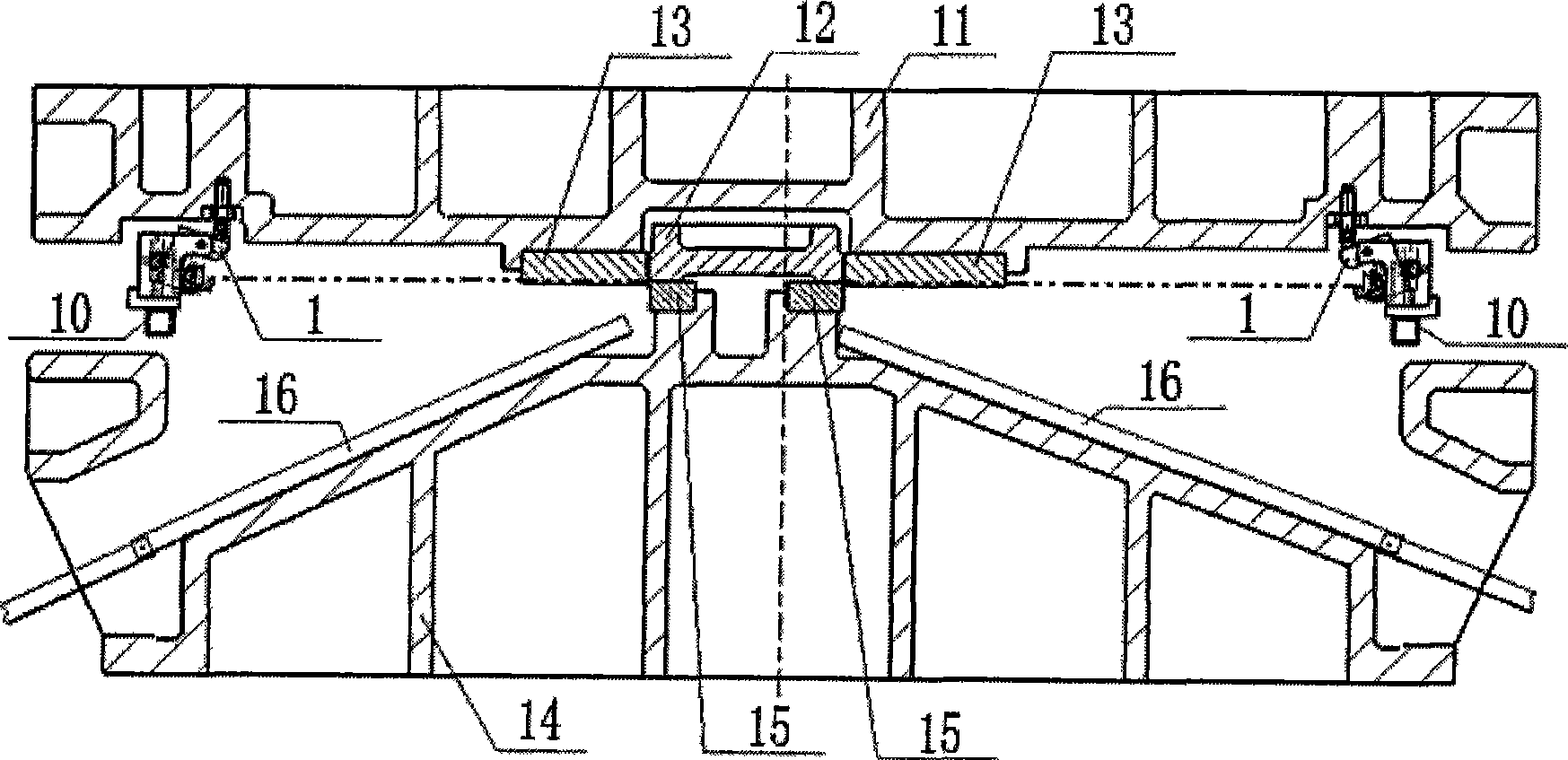

[0017] The invention proposes a feeding mechanism for a blanking die. Lifting block 5 is installed on the fixed support 8, and is connected with support shaft pin 4, and support 8 is provided with lifting block reset device; 11 is provided with the ejector pin that cooperates with material lifting block 5. When working, the ejector rod moves downward with the upper die base 11. When cutting materials, the ejector rod is pushed against the outside of the lifting block 5. The lifting block 5 rotates with the shaft pin 4 as the center of the circle. Block 5 exits.

[0018] The reset device for lifting the material block is a spring reset mechanism, such as a torsion spring mechanism, an extension spring mechanism, and a compression spring mechanism, and other mechanisms such as a rotary positioning block can also be used to realize the reset of the material lifting block 5 . The spring return mechanism shown in the figure includes a mandrel 7 installed in the support 8 and a sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap