Laser twin-wire indirect arc hybrid welding device and wire feeding speed prediction calculation method

A composite welding and wire feeding speed technology, which is applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of precise adjustment of double wire and laser spot and difficult determination of wire feeding speed, and achieves easy implementation, convenient operation, and design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

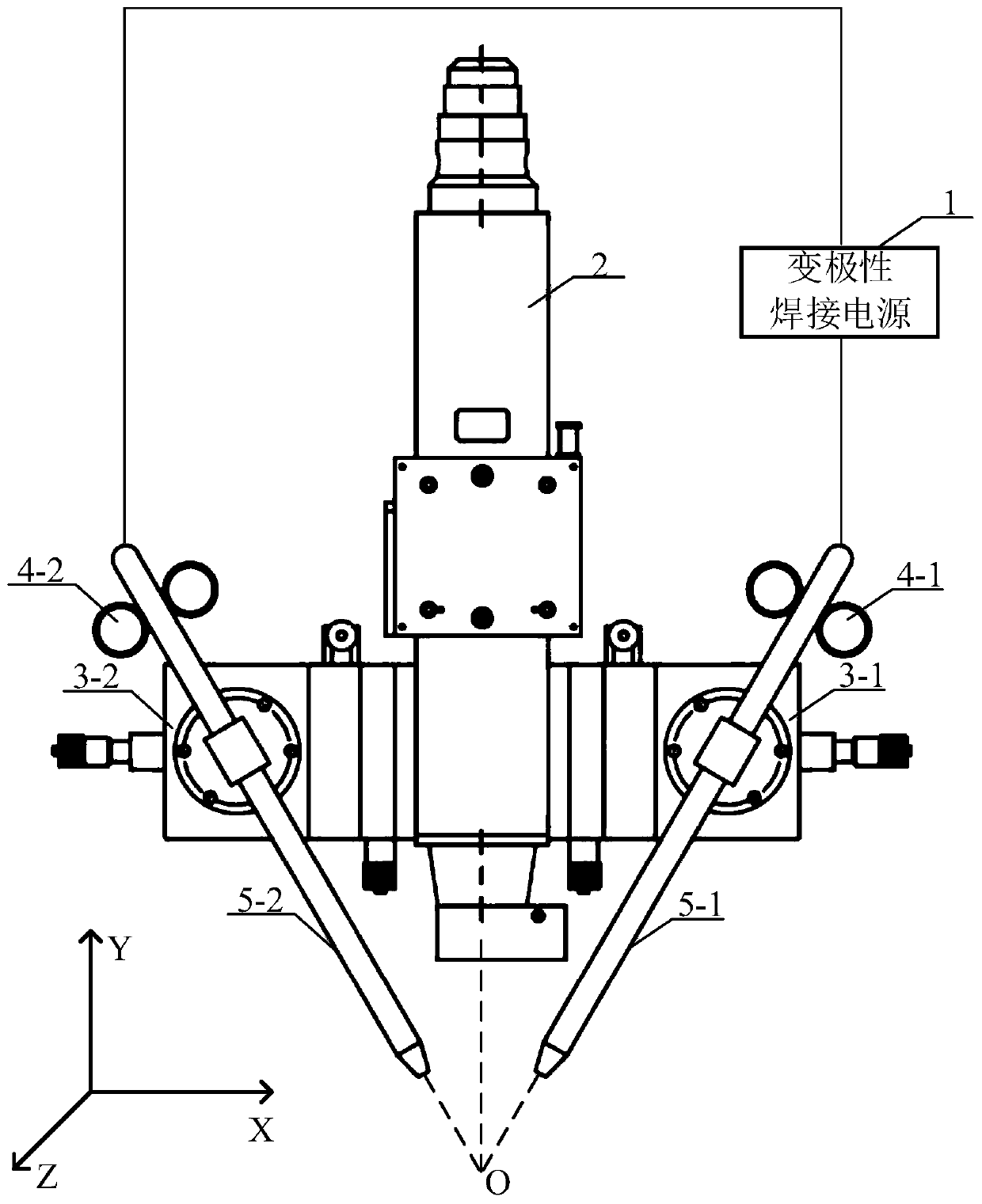

[0024] The equipment used in this embodiment includes: variable polarity welding power supply 1, laser welding head 2, first welding wire position adjustment mechanism 3-1, second welding wire position adjustment mechanism 3-2, first welding wire 5-1, second welding wire 5-2. The first welding wire 5-1 and the second welding wire 5-2 are adjusted by the first welding wire position adjustment mechanism 3-1 and the second welding wire position adjustment mechanism 3-2 to be coplanar with the laser beam and to intersect at point O along the feeding direction.

[0025] The first welding wire 5-1 and the second welding wire 5-2 are ER50-6 carbon steel welding wires with a diameter of 1.2mm, and the output current of the variable polarity welding power supply is a square wave waveform with a current amplitude of 100A. When the current is 100A, the anode melting velocity va of the first welding wire 5-1 and the second welding wire 5-2 is calibrated to be 2.4m / min, and the cathode mel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap