Feeder

A feeder and rack technology, applied in the field of stainless steel ceiling gusset processing, can solve the problems of low efficiency, unstable quality and high production cost, and achieve the effects of stable processing quality, low processing cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

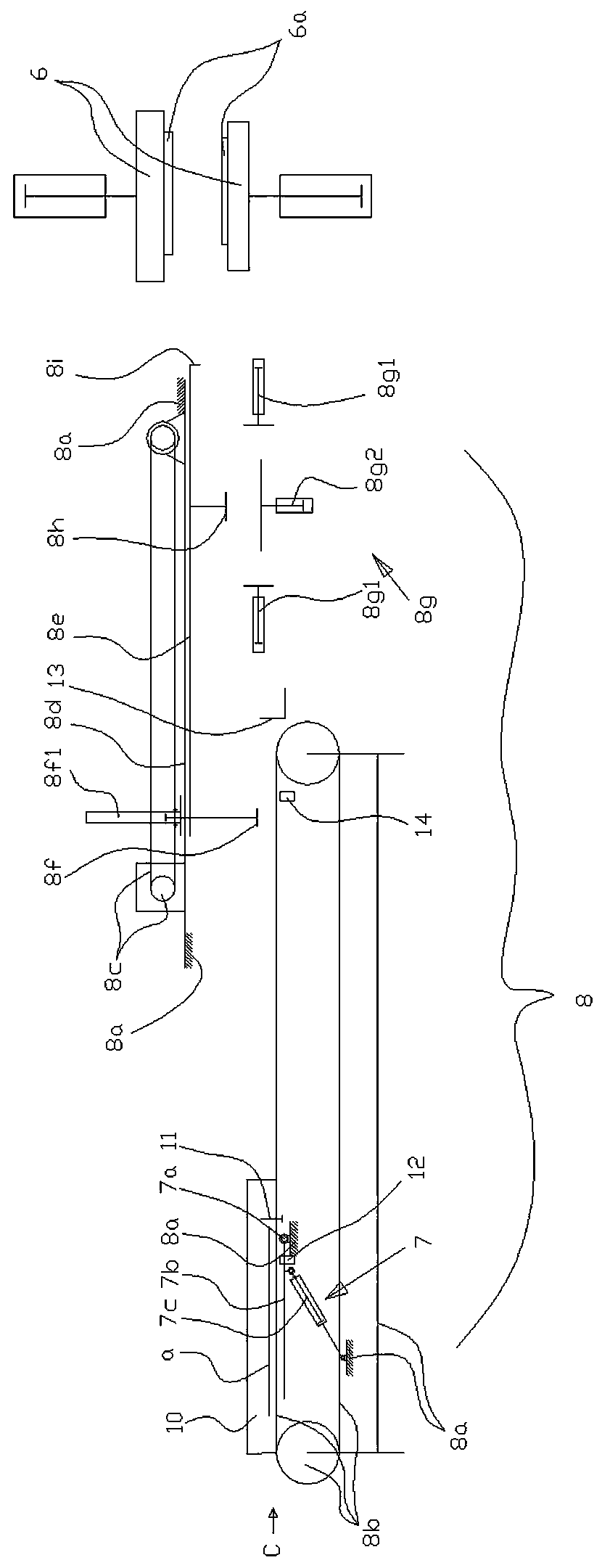

[0014] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

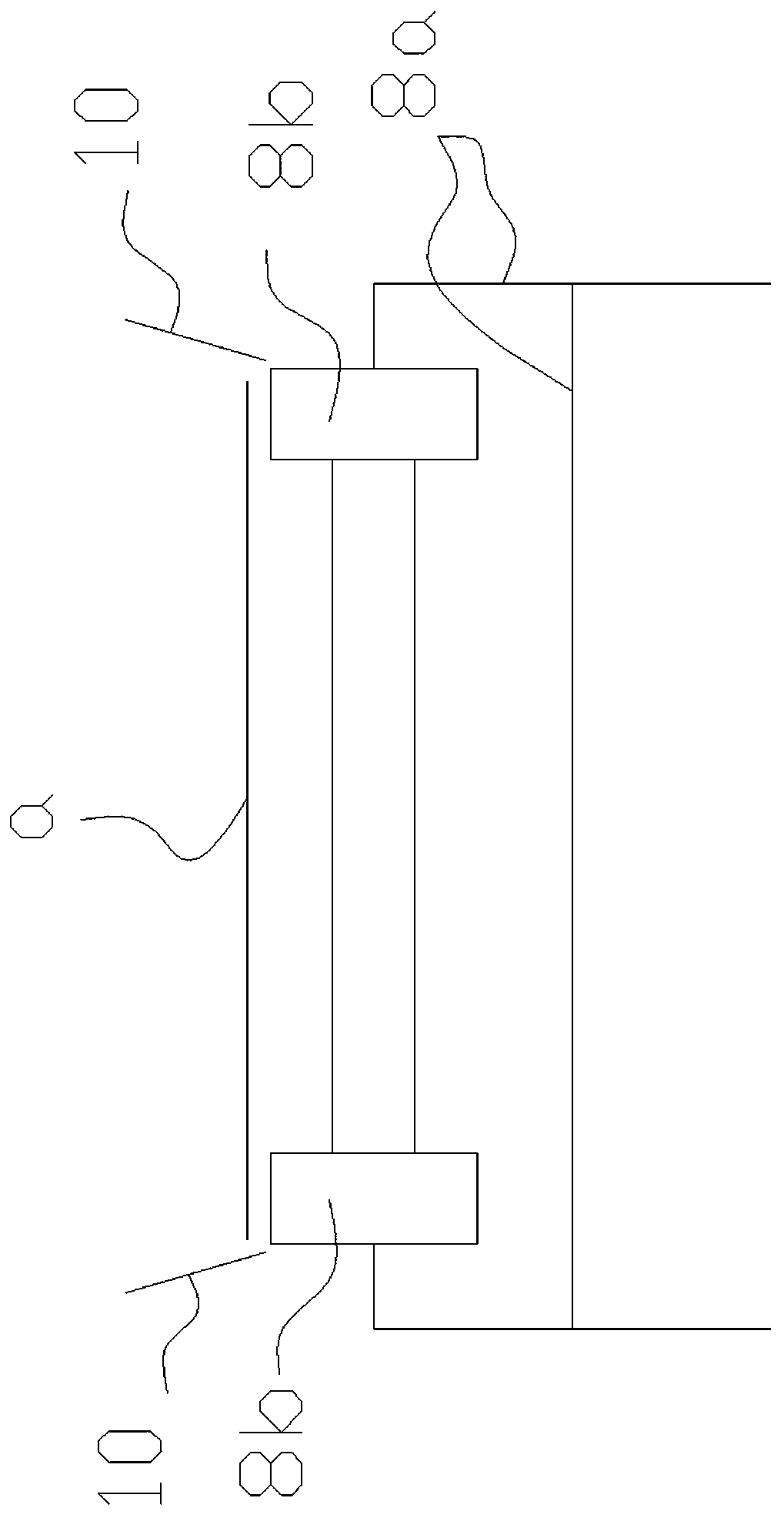

[0015] Such as figure 1 As shown, the feeder 8 of the present invention includes a power transmission belt 8b arranged on both sides of the frame 8a, a first sucker mechanism 8f driven by a power 8c through a moving frame 8e moving back and forth along a track 8d, and a plate positioning mechanism located above the power transmission belt 8b. The mechanism 8g and the second sucker mechanism 8h located above the plate positioning mechanism 8g are driven by the power 8c through the moving frame 8e moving back and forth along the track 8d.

[0016] The front end of the power transmission belt 8b is provided with a turning machine 7, and the turning machine includes a turning plate 7b that is arranged on the frame 8a and is located between the power transmission belts 8b on both sides along the rotating shaft 7a, and a power mechanism 7c that drives the turnin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap