Complementary type sealing structure for housing of power steering gear

A power steering gear and sealing structure technology, which is applied to the sealing of the engine, fluid steering mechanism, engine components, etc., can solve the problems of large steering torque, leakage, and deterioration of the working environment, and achieve high bearing pressure, tight sealing, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

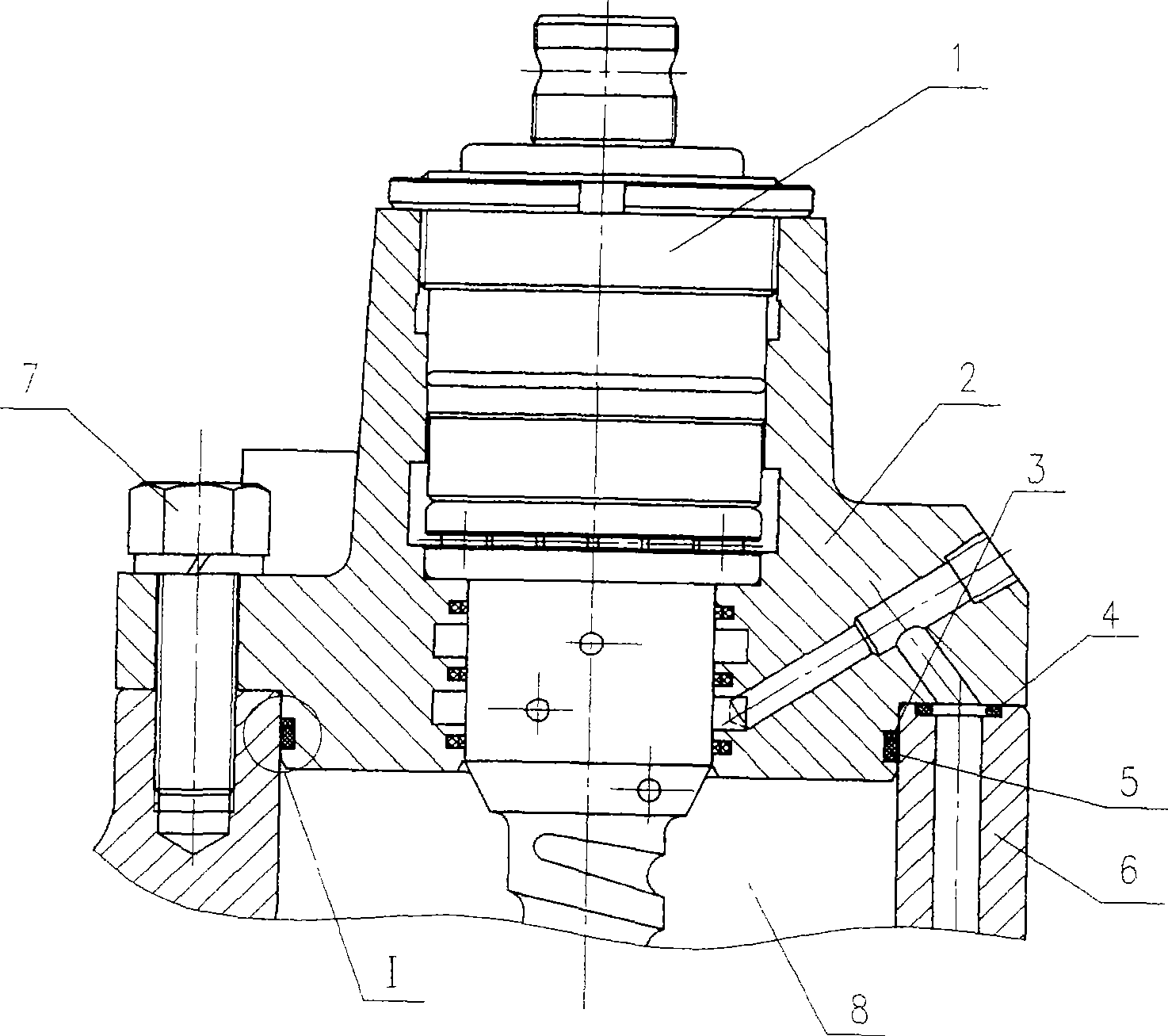

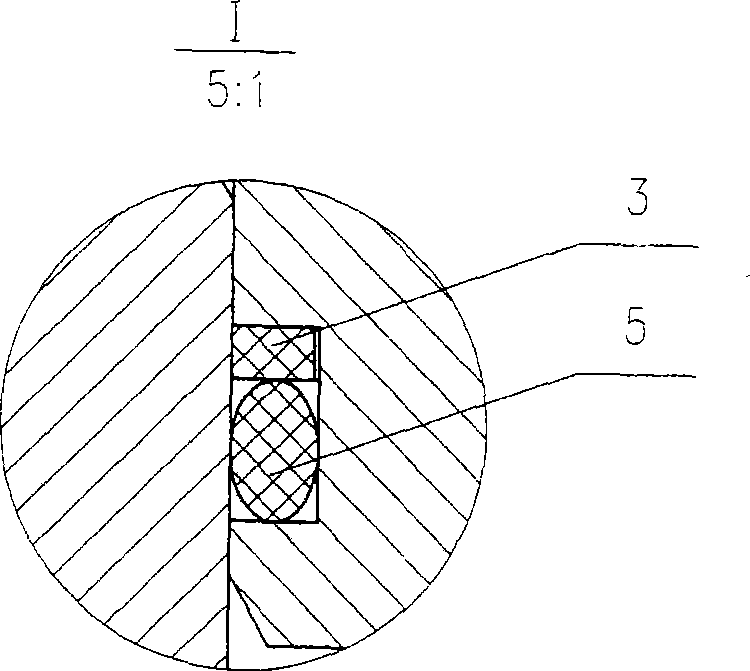

[0013] Example 1: figure 1 The complementary sealing structure of the housing of the power steering gear shown includes a valve body 2 , a sealing ring 3 , a sealing ring 5 and a housing 6 . After the valve body 2 is equipped with a valve core assembly 1 , it is tightly matched with the housing 6 and the gasket 4 and is fixedly connected with bolts 7 . figure 2 The partial enlarged schematic diagram of the complementary sealing structure composed of two seals with different structures is shown. The cross section of the sealing ring 3 is rectangular and the material is polytetrafluoroethylene. The cross section of the sealing ring 5 is circular and the material is oil-resistant rubber. . The sealing ring 3 and the sealing ring 5 are directly installed in the annular groove on the cylinder of the matching section of the valve body 2 and the inner hole of the housing 6 . The sealing ring 3 is installed on the inner upper side of the annular groove, and the sealing ring 5 is in...

Embodiment 2

[0014] Embodiment 2: On the power steering gear of the same type, when the outer diameters of the sealing rings 3 and 5 are increased to φ117.8mm, the sealing effect is the same as that of the embodiment 1 except that the assembly difficulty is slightly increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com