Fuzzy control method for temperature distribution of inner steel bloom of heating stove

A technology of temperature distribution and fuzzy control, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems that it is difficult to effectively ensure the heating process of the billet to be heated, and the influence and difficulty of the temperature distribution of the billet are not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

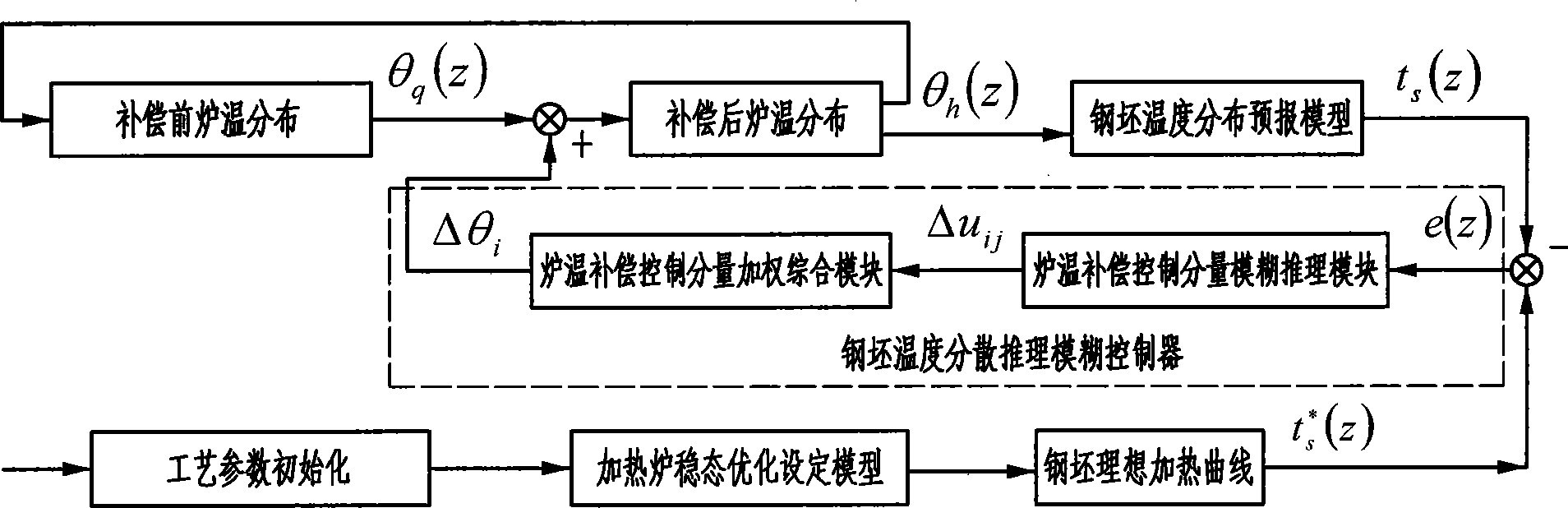

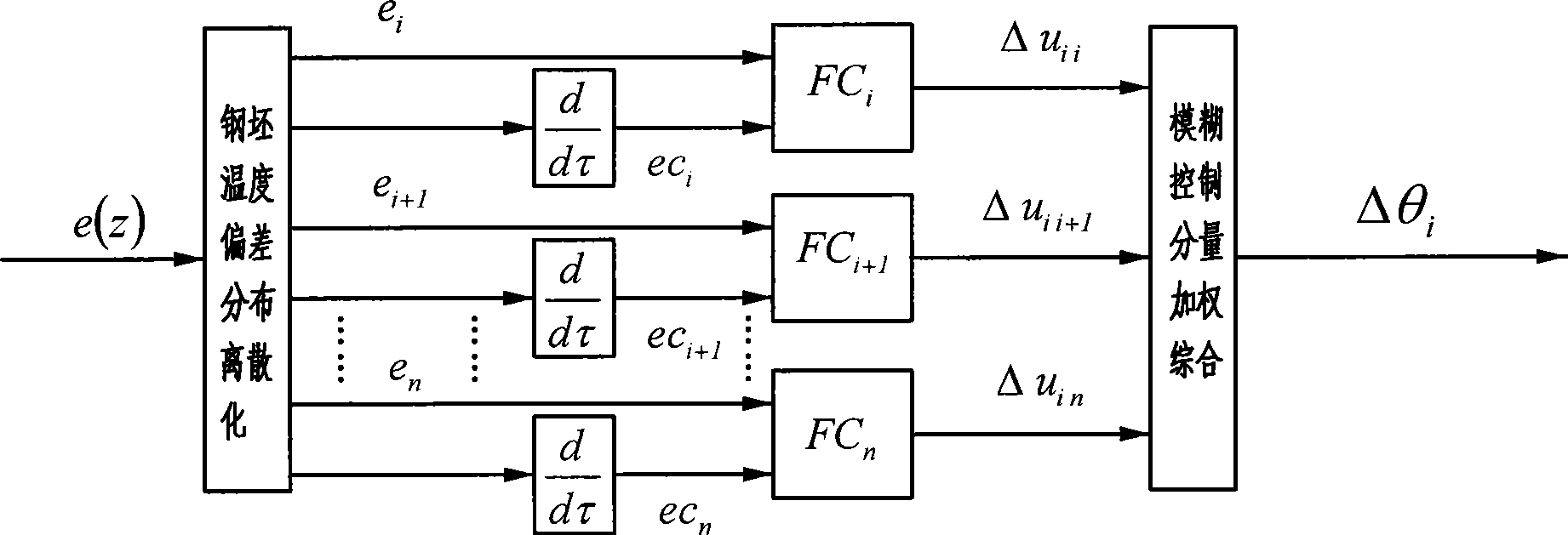

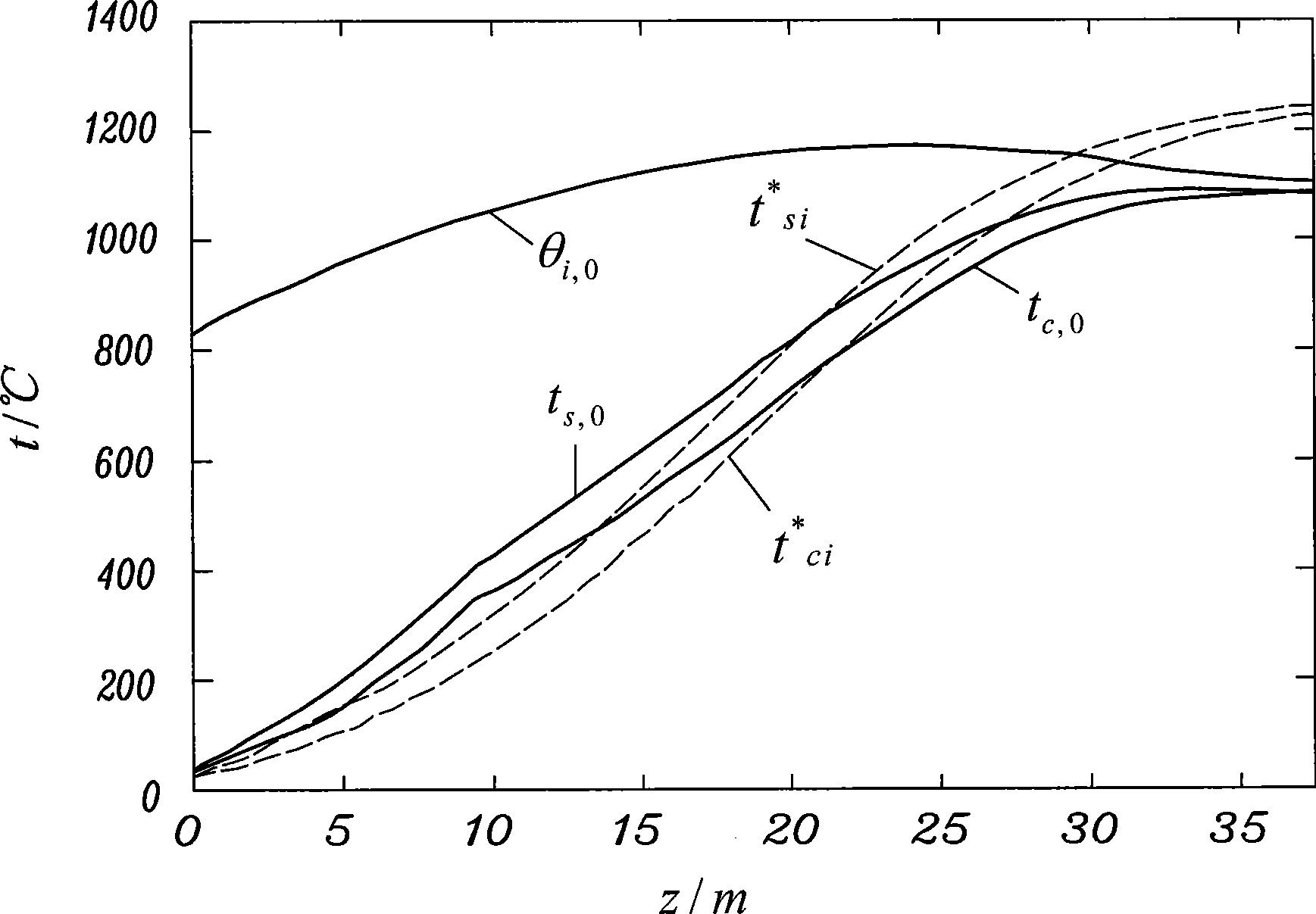

[0028] A fuzzy control method for the temperature distribution of steel slabs in a heating furnace, the method includes dividing the effective furnace length of the heating furnace into n sections, setting the corresponding furnace temperature compensation discrete point i, and using the steel slab temperature distribution prediction model and the heating furnace stability State optimization setting model to determine the ideal curve t of the average temperature of the billet surface * s (z) and billet center temperature ideal curve t * c Step (a) of (z).

[0029] In step (1), the billet temperature distribution prediction model includes the billet unsteady heat conduction equation and corresponding boundary conditions and initial conditions, specifically:

[0030] ρc ∂ t ( τ , x , y ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com