Pre-stress high-strength concrete pipe pile static-pressure construction method

A construction method and technology for concrete pipe piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as affecting construction quality, inclined piles, and cracking at connecting piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

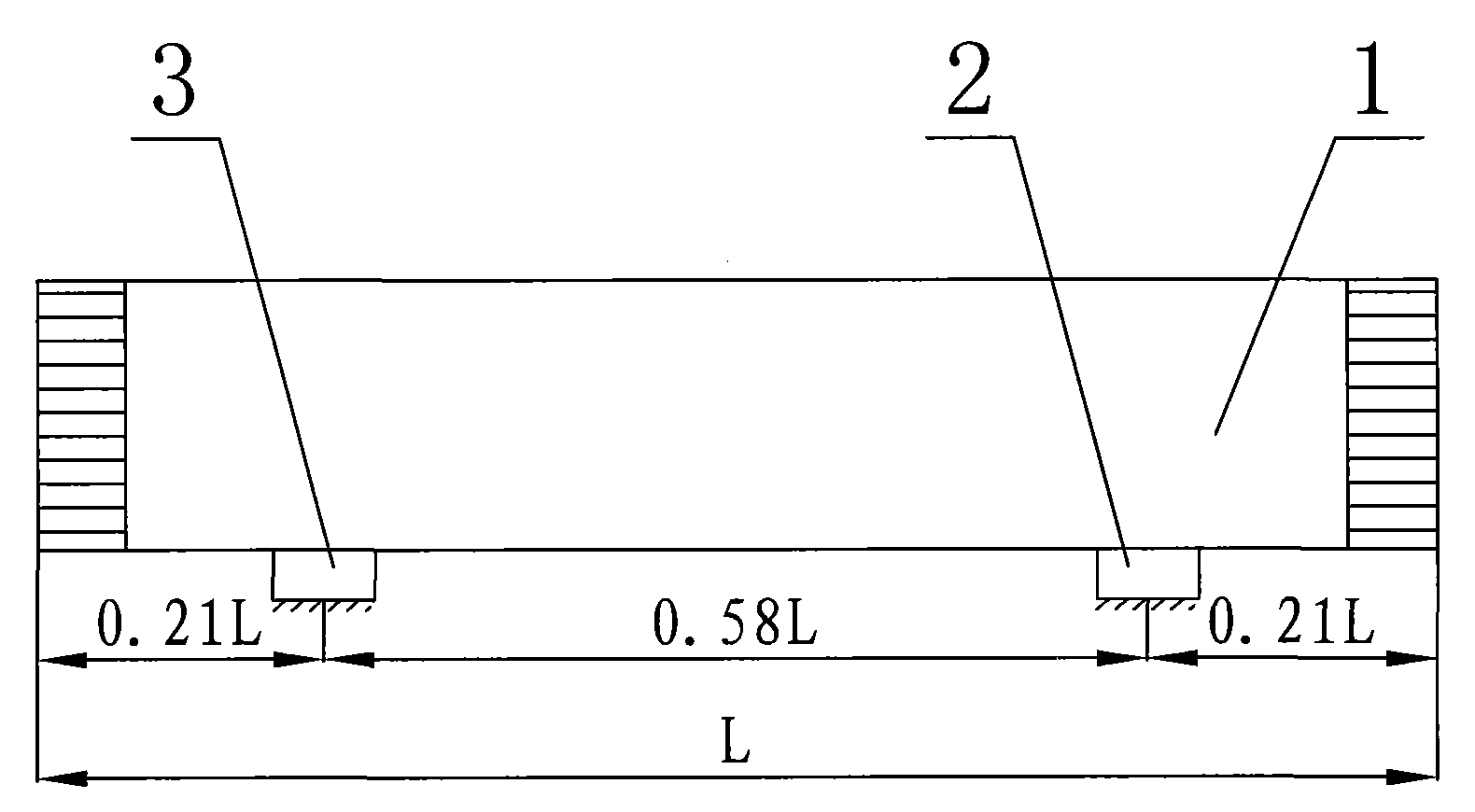

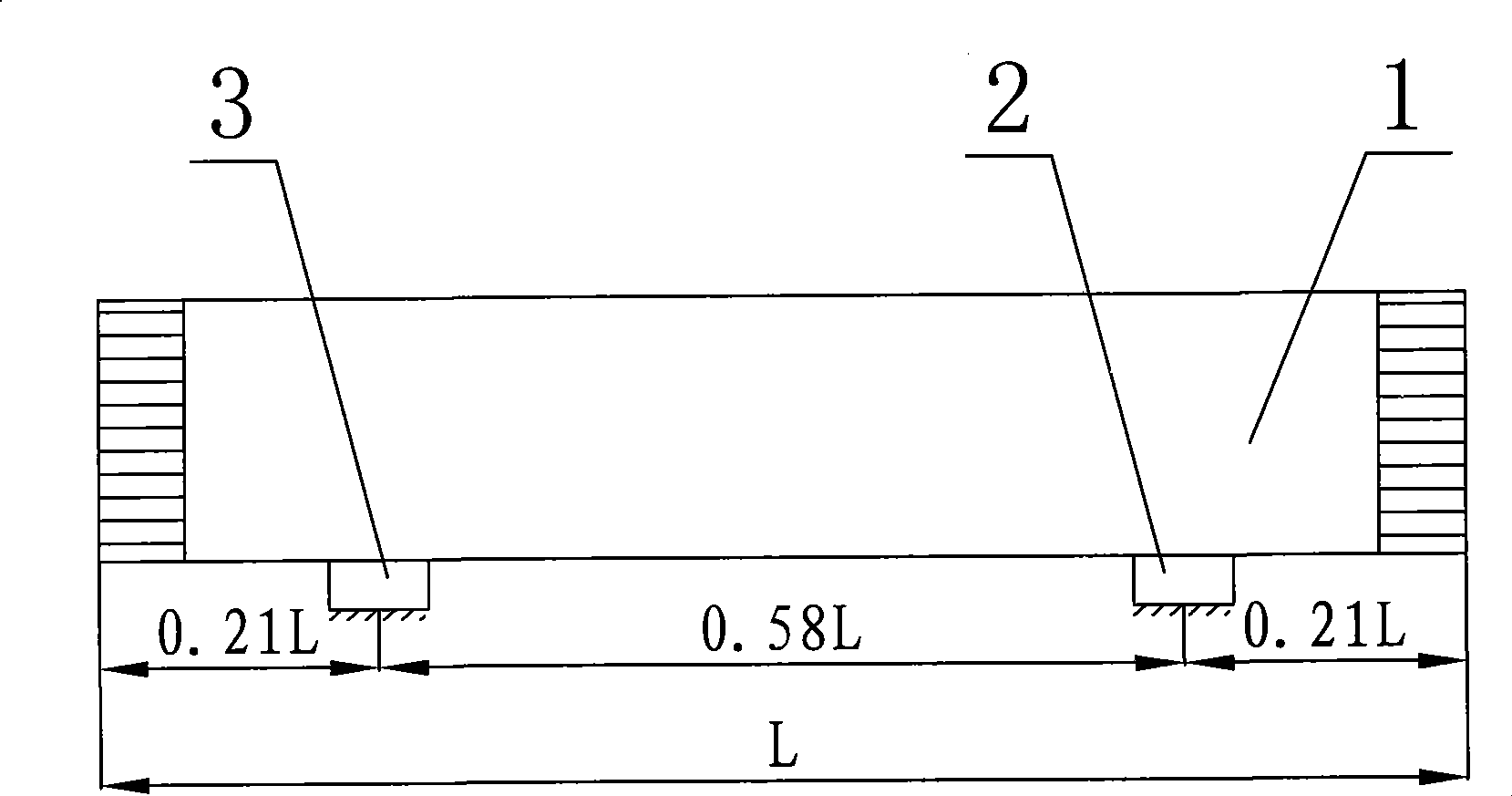

[0031] The static pressure construction methods of prestressed high-strength concrete pipe piles may include:

[0032] 1. Protection of finished prestressed high-strength concrete pipe piles

[0033] 1) Prestressed high-strength concrete pipe piles are divided into several specifications according to the outer diameter of 300, 400, 500, 550, 600, 800, 1000mm, etc., and are processed by professional manufacturers;

[0034] 2) Prestressed high-strength concrete pipe piles should be stacked separately according to the specifications, models, and lengths. The number of stacked layers should not exceed the requirements in Table 1. The stacking site should be solid and flat. The supporting points of the skids should be on the same level (if the yard foundation has been specially treated, it can also be laid flat on the ground);

[0035] Table 1 Stacking layers of prestressed high-strength concrete pipe piles

[0036] outer diameter (mm)

300

400

500-600

800-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com