Electroosmosis-load combined consolidometer

A consolidation instrument and electroosmosis technology, applied in the field of electroosmosis-loading combined consolidation instrument, can solve the problems of inability to measure parameters, lack of design and calculation parameters, and incompletely clear action mechanism and properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

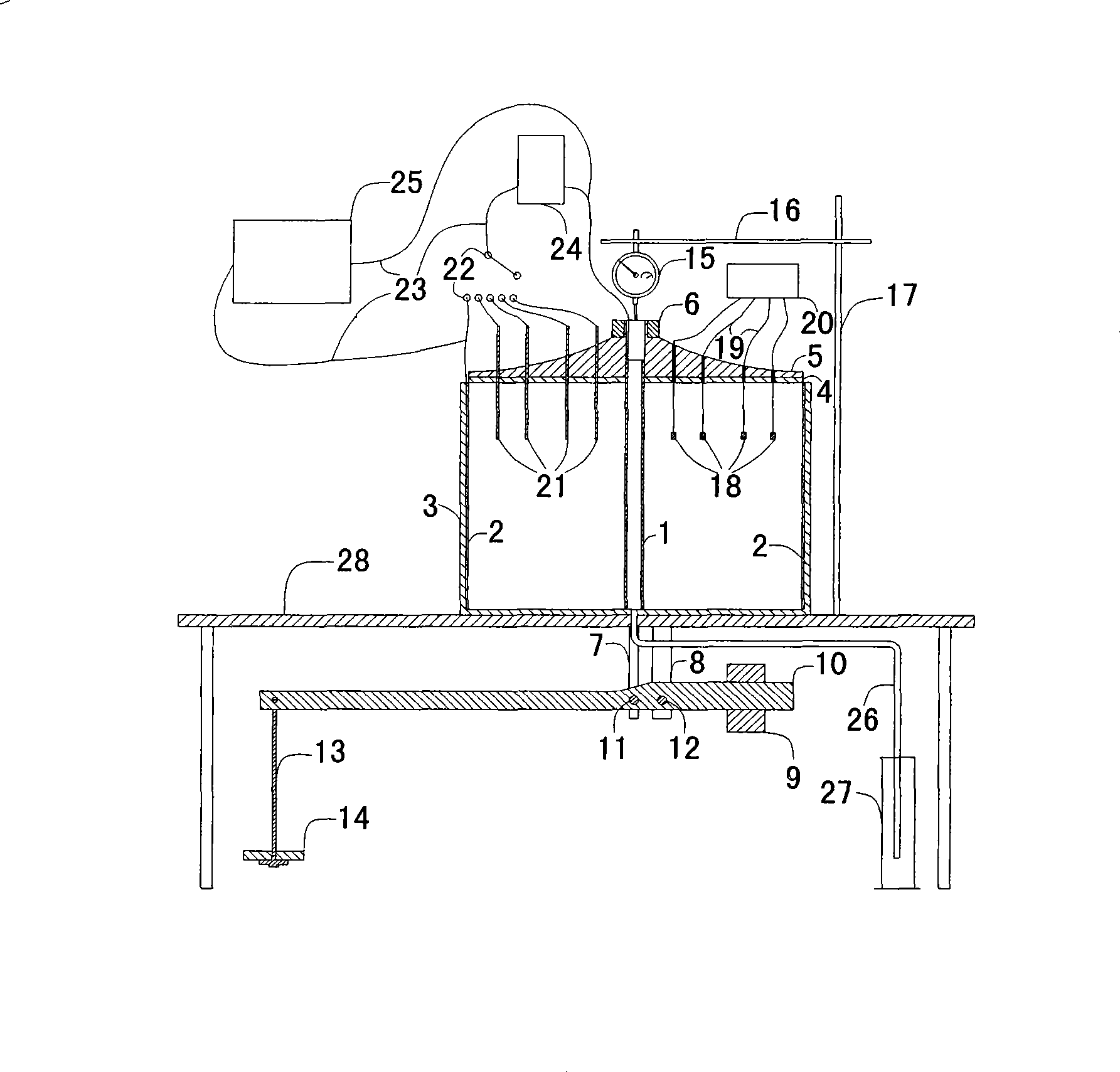

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] As shown in the drawings, the present invention vertically arranges an electroosmotic cathode 1 at the central axis of a cylindrical container 3 where soil samples are placed, and an electroosmotic anode 2 is arranged close to the inner wall of the cylindrical container 3 . The top of the cylindrical container 3 is provided with a piston-type loading top cover 5 , and the underside of the loading top cover 5 is covered with an insulating isolation plate 4 , and a top loading rod 6 is installed on the loading top cover 5 . The center of the bottom of the cylindrical container 3 is provided with a drainage hole, which is connected to the measuring cylinder 27 through the drainage hose 26, and the water discharged from the consolidation of the soil sample is gathered to the electroosmotic cathode 1 under the action of the electric field, and flows in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com