Display module and its display module frame

A display module and display technology, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of bright lines, large locking force, cracking of optical sheets or liquid crystal panels on LCD panels, and achieves convenient production line installation, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

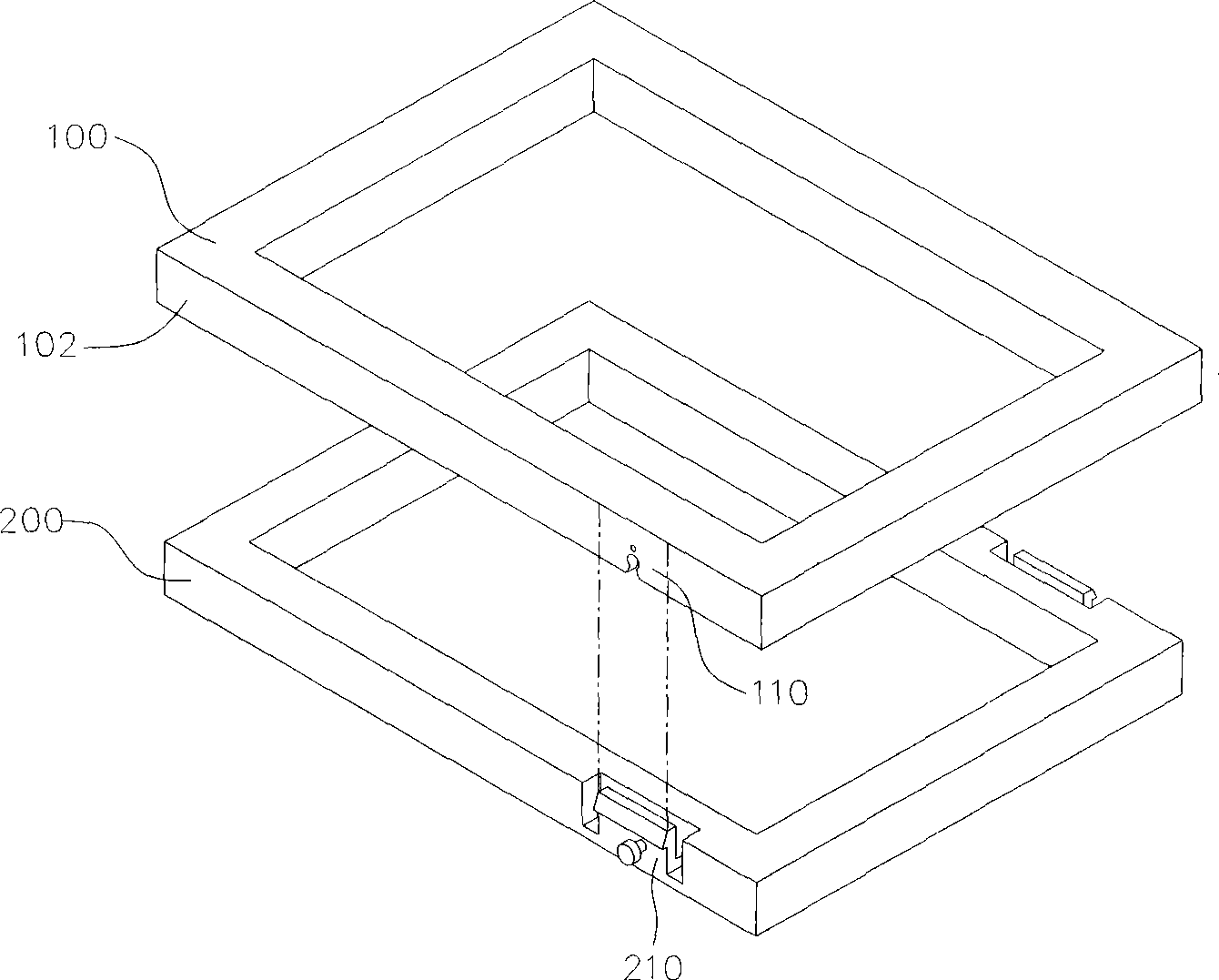

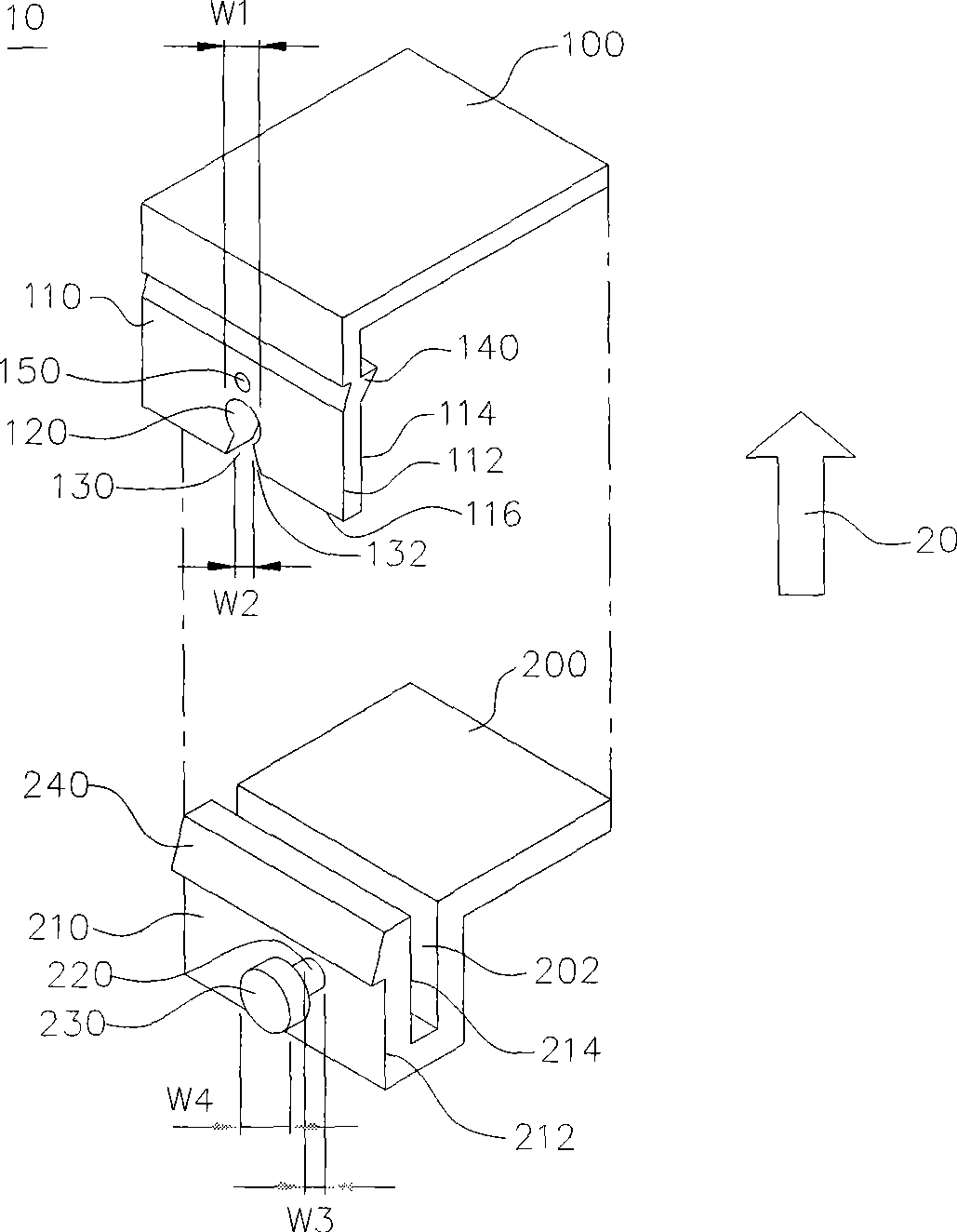

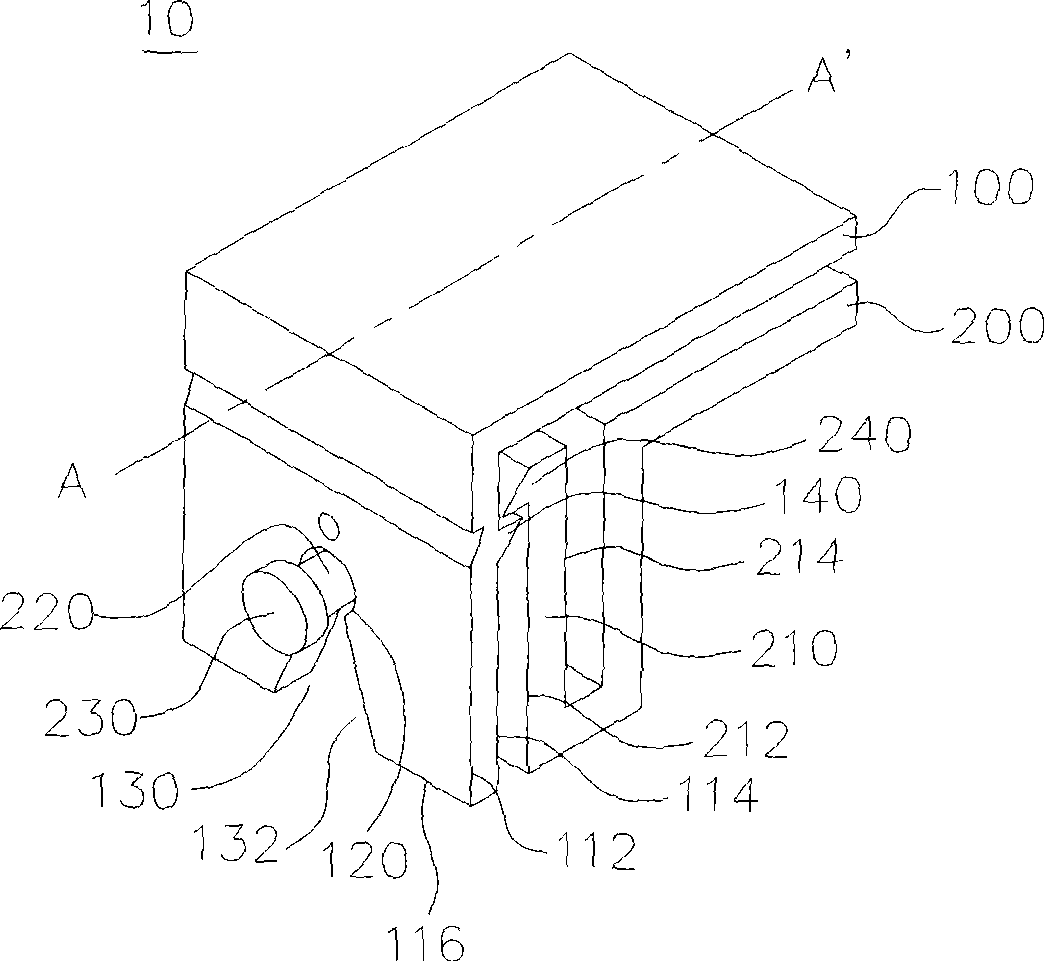

[0050] Please refer to figure 1, which is an exploded view of a display module frame 10 according to an embodiment of the present invention. The display module frame 10 at least includes an outer frame 100 and an inner frame 200 . The outer frame 100 and the inner frame 200 can be connected to each other and assembled. In an embodiment of the present invention, the outer frame 100 can be sleeved outside the inner frame 200 . The inner wall of the outer frame 100 adjoins or adheres to the outer wall of the inner frame 200 .

[0051] The outer frame 100 may be a casing, a frame, or a front bezel of a display, and the like. The inner bezel 200 may be a frame, a front bezel, a back bezel, or the like. In the embodiment of the present invention, the outer frame 100 is a front frame, and the inner frame 200 is a frame or a plastic frame.

[0052] Please also refer to figure 1 , Figure 2A , Figure 2B and Figure 2C . Figure 2A is like figure 1 A partial exploded view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com