Part dismantling drawing system and method

A part and part numbering technology, applied in the field of parts dismantling system, to improve the efficiency of dismantling, save time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

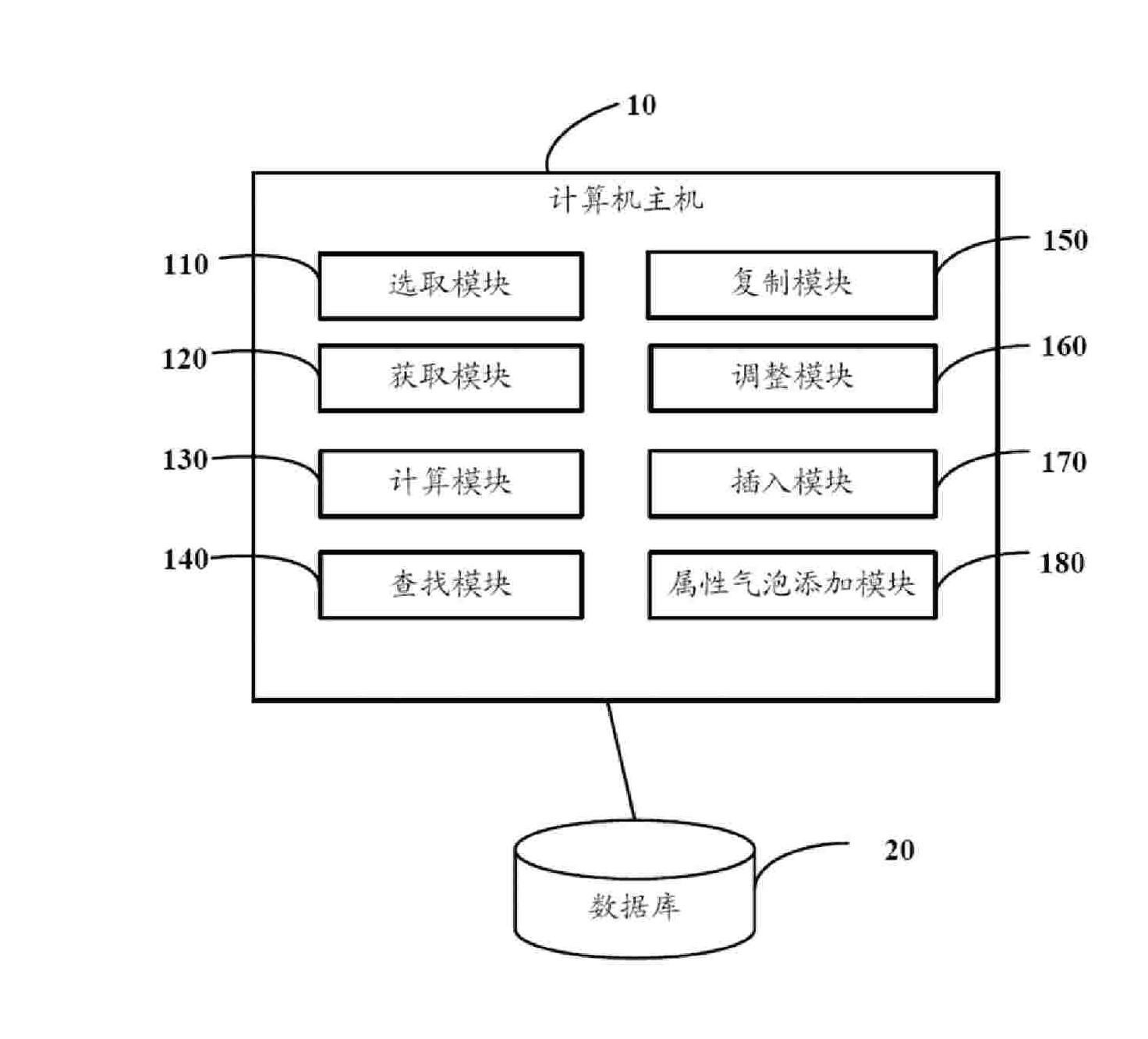

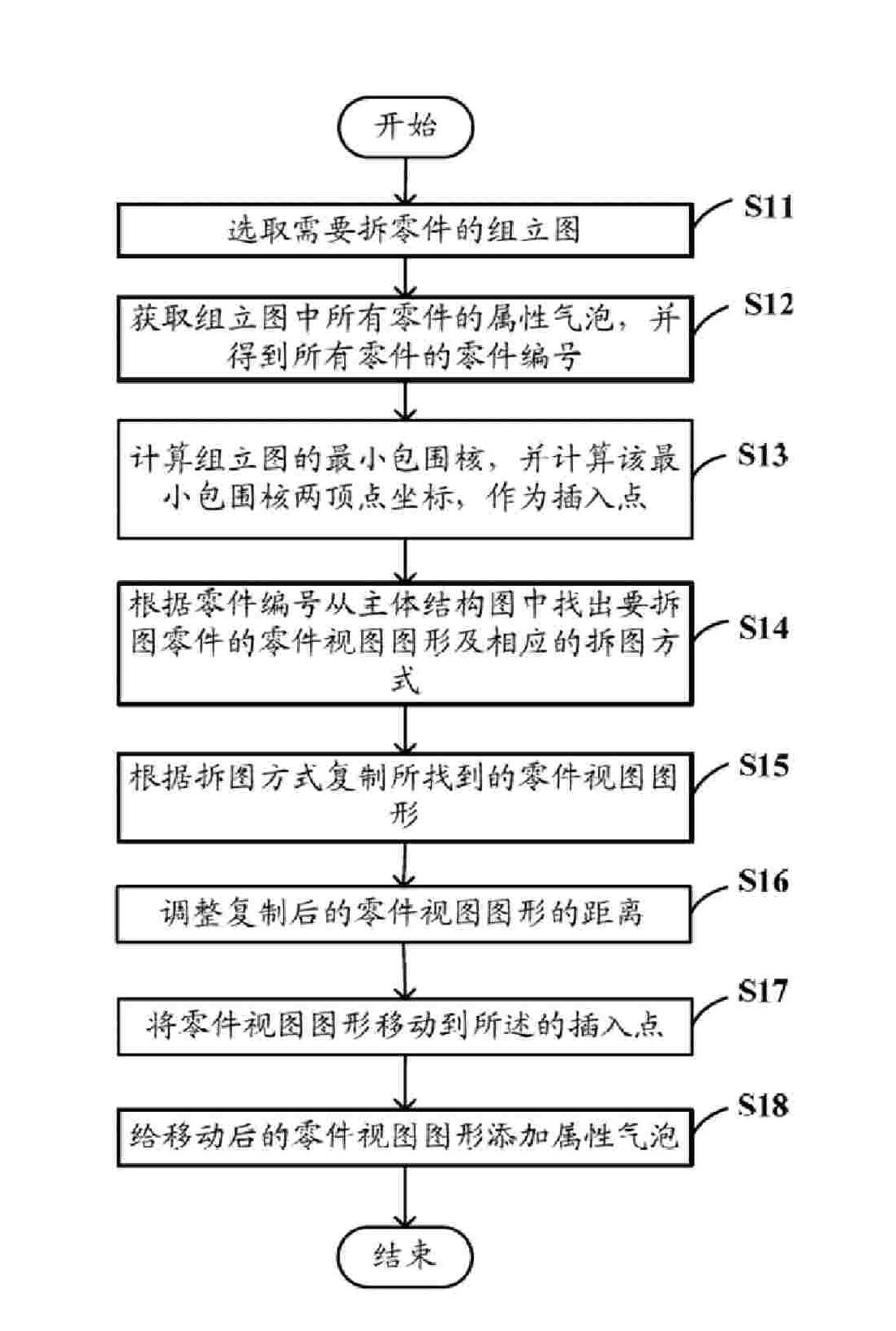

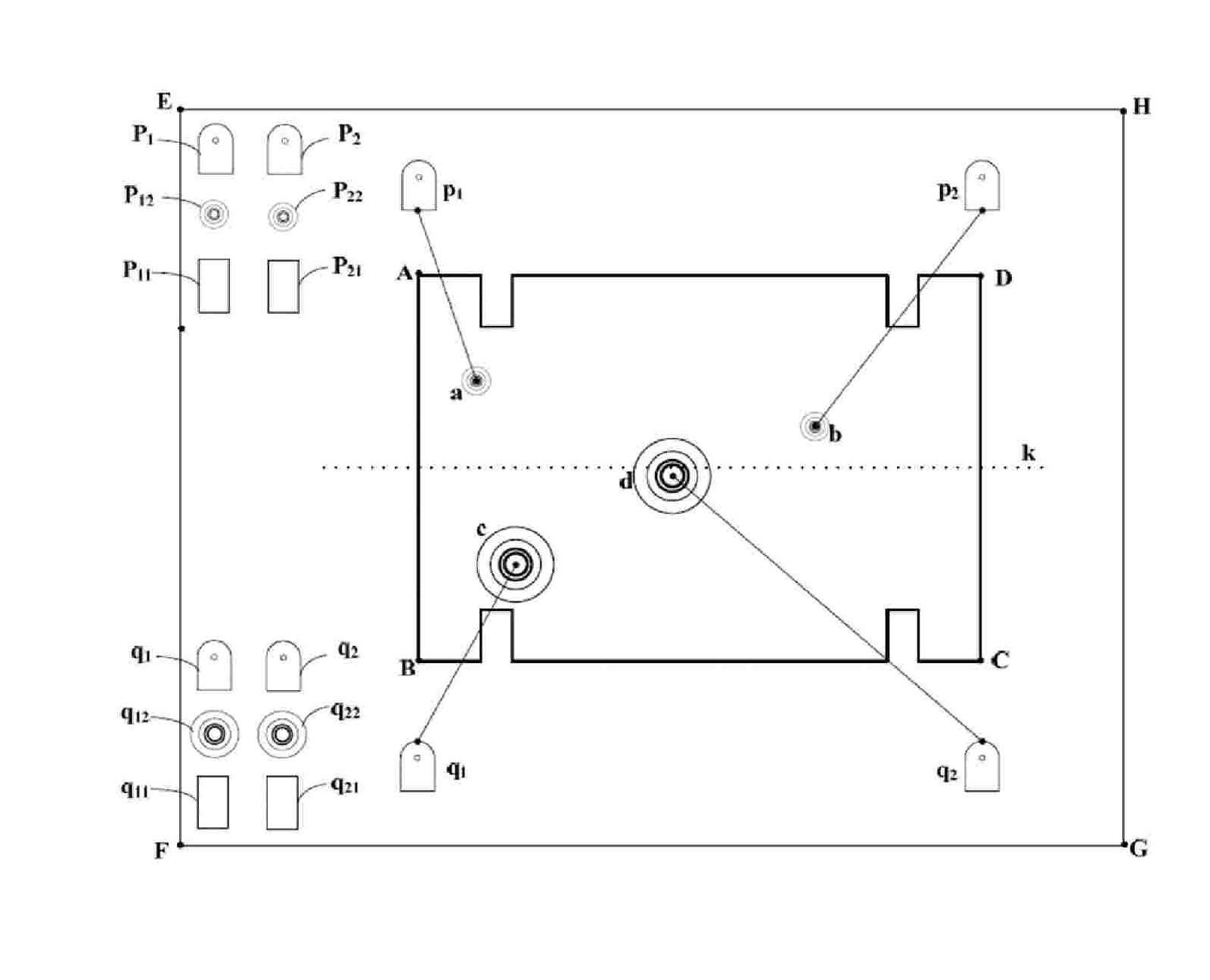

[0016] Such as figure 1 As shown, it is a structure diagram of a preferred embodiment of the parts dismantling system of the present invention. The part drawing system of the present invention runs in the main computer 10, and the main computer 10 is connected with a database 20, and the database 20 is used to store the mold assembly diagram and the main structure diagram in the mold design. The main structure diagram includes a front view, a bottom view and a right view. The mold assembly diagram is a diagram formed by taking out some required parts from the main structure diagram of the mold and combining them together. The host computer 10 mainly includes a selection module 110 , an acquisition module 120 , a calculation module 130 , a search module 140 , a copy module 150 , an adjustment module 160 , an insertion module 170 and an attribute bubble addition module 180 .

[0017] The selection module 110 is used to select the mold assembly drawings that need to be disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com