Novel apparatus used for film engraving and dotting of thin-film solar cell

A technology of solar cells and thin films, applied in circuits, electrical components, laser welding equipment, etc., can solve the problems of inconsistent marking quality, repeated lines, repeated points, etc., to avoid marking errors, automatic and accurate alignment, and realize alignment bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

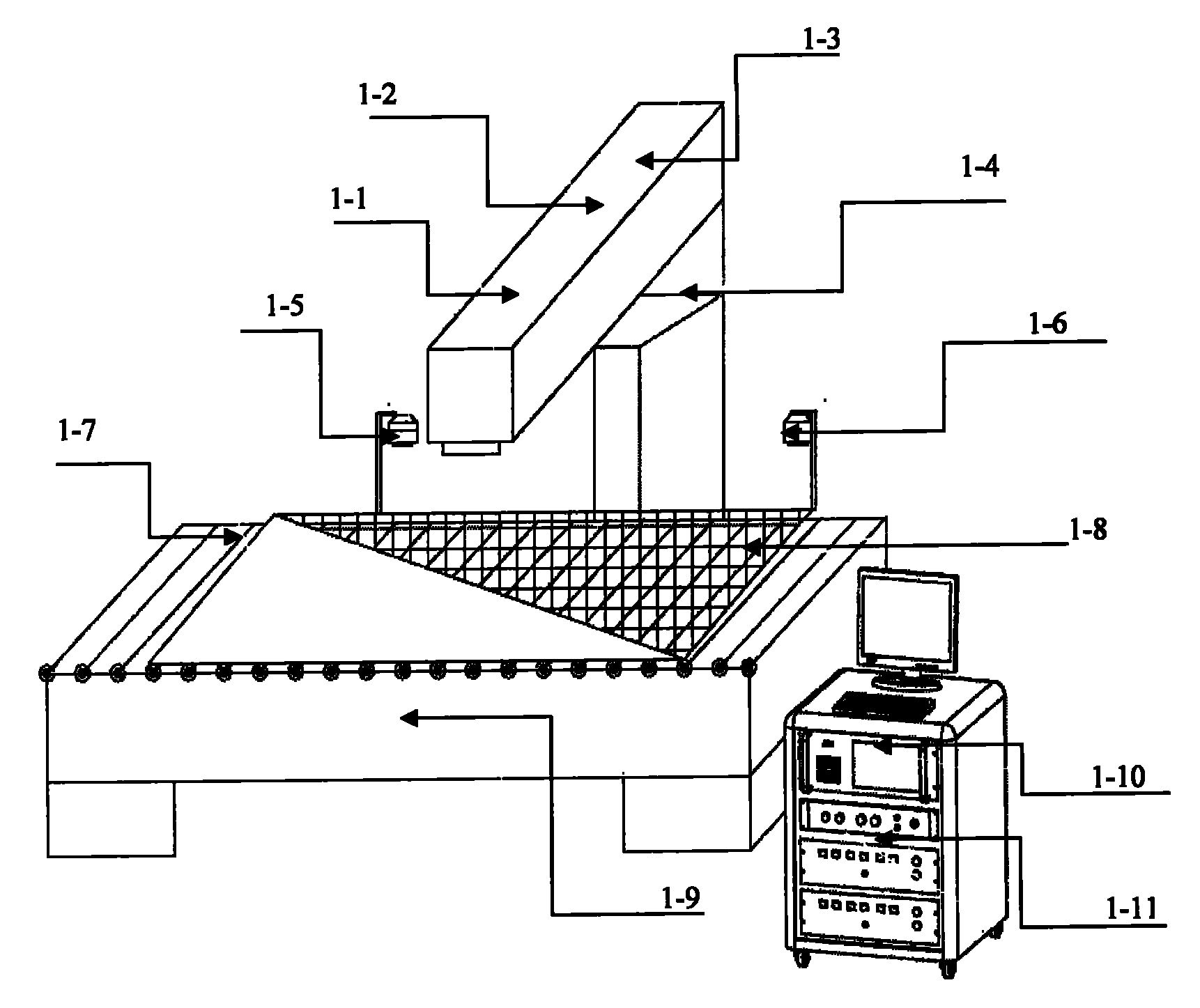

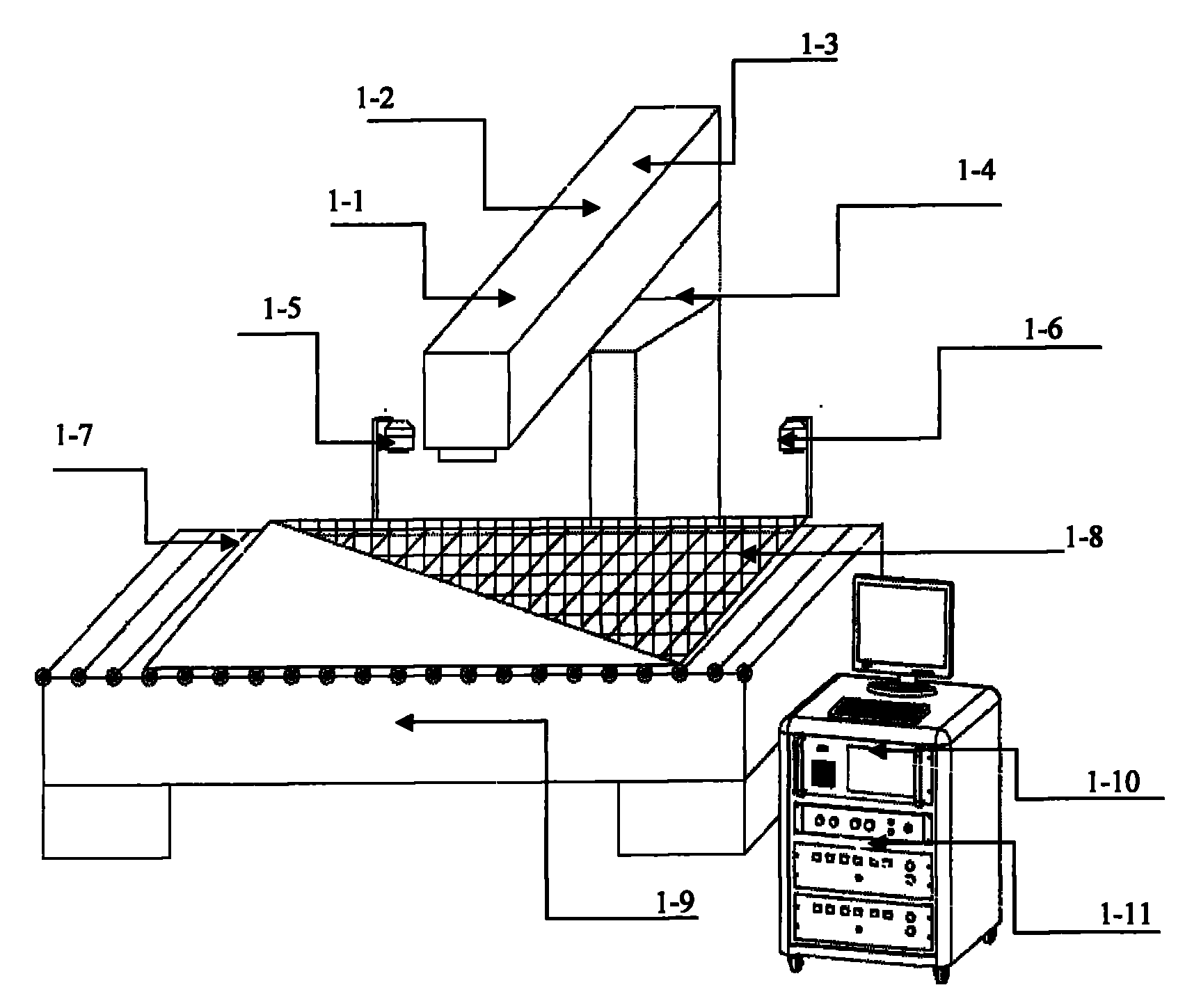

Embodiment 1

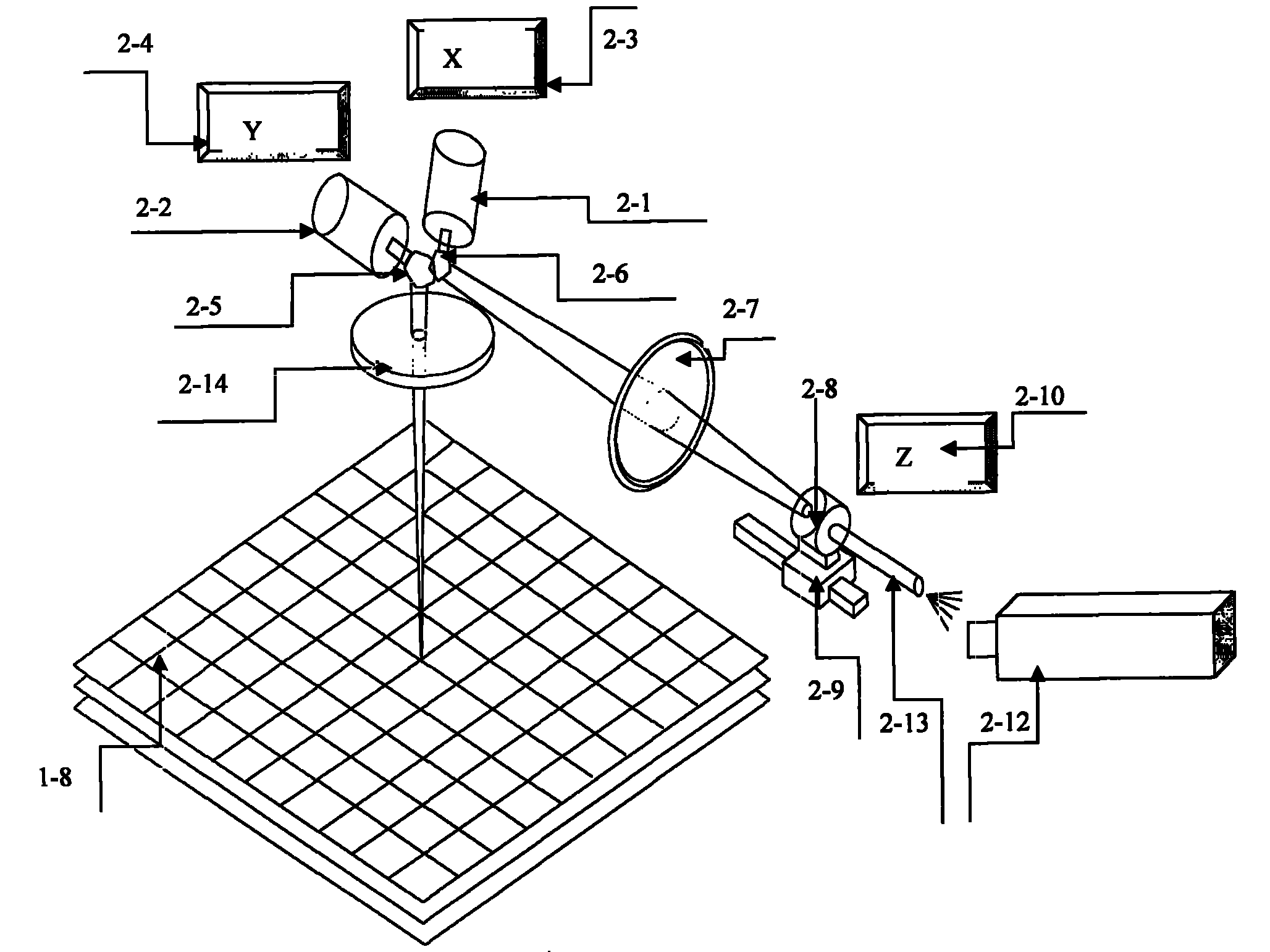

[0034] Example 1: Marking and producing thin-film solar cell substrates 1-8 with a cell spacing of 20mm in length and 10mm in width, and a width of 1000mm×1000×0.8mm. Front electrode pattern production: Place the transparent conductive film of ITO, ZNO or SNO2 with the size of 1000mm×1000×0.8mm face up into the first marking area in Figure 1, the auxiliary roller feeding mechanism 1 on the mirror table 1-9 -7, under the control of the industrial computer 1-10, we use the In-Sight 5400 series vision sensor of Cognex Corporation (COGNEX) as an independent vision system to deploy in this application environment, and cooperate with its vision software to implement The automatic alignment function, industrial computer 1-10 data analysis allows the laser generator 1-3 to accurately position the object. In a standard application environment, the entire response time of image evaluation is about 180 milliseconds, and its resolution is 640*480 pixel units.

[0035] The automatic camera p...

Embodiment 2

[0039] Example 2: Marking and producing thin-film solar cell substrates with a cell spacing of 30mm in length and 10mm in width, and a width of 1200mm×800×0.6mm.

[0040] Front electrode pattern production: place the transparent conductive film of size 1200mm×800×0.6mm face down into the first marking area in Figure 1, the auxiliary roller feeding mechanism 1-7 on the mirror table 1-9, in the industrial control The control of the machine 1-10 moves forward slowly, the same as the above steps. After the solar film substrate reaches the specified position, the automatic camera positioning subsystem 1-6 realizes the search for the positioning line on the transparent conductive film surface, and immediately stops it when found Feeding mechanism 1-7. After positioning, we use a digital laser sensor to detect the height of the current thin-film solar panel surface to the vibrating lens, and directly go to the marking software through the corresponding interface to modify the current re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com