Device for lifting elevator component

A technology of parts and elevators, which is applied to lifting equipment, elevators, transportation and packaging in mines, can solve problems such as reduced operating efficiency, heavy burden on operators, and difficulties, and achieve good results in operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

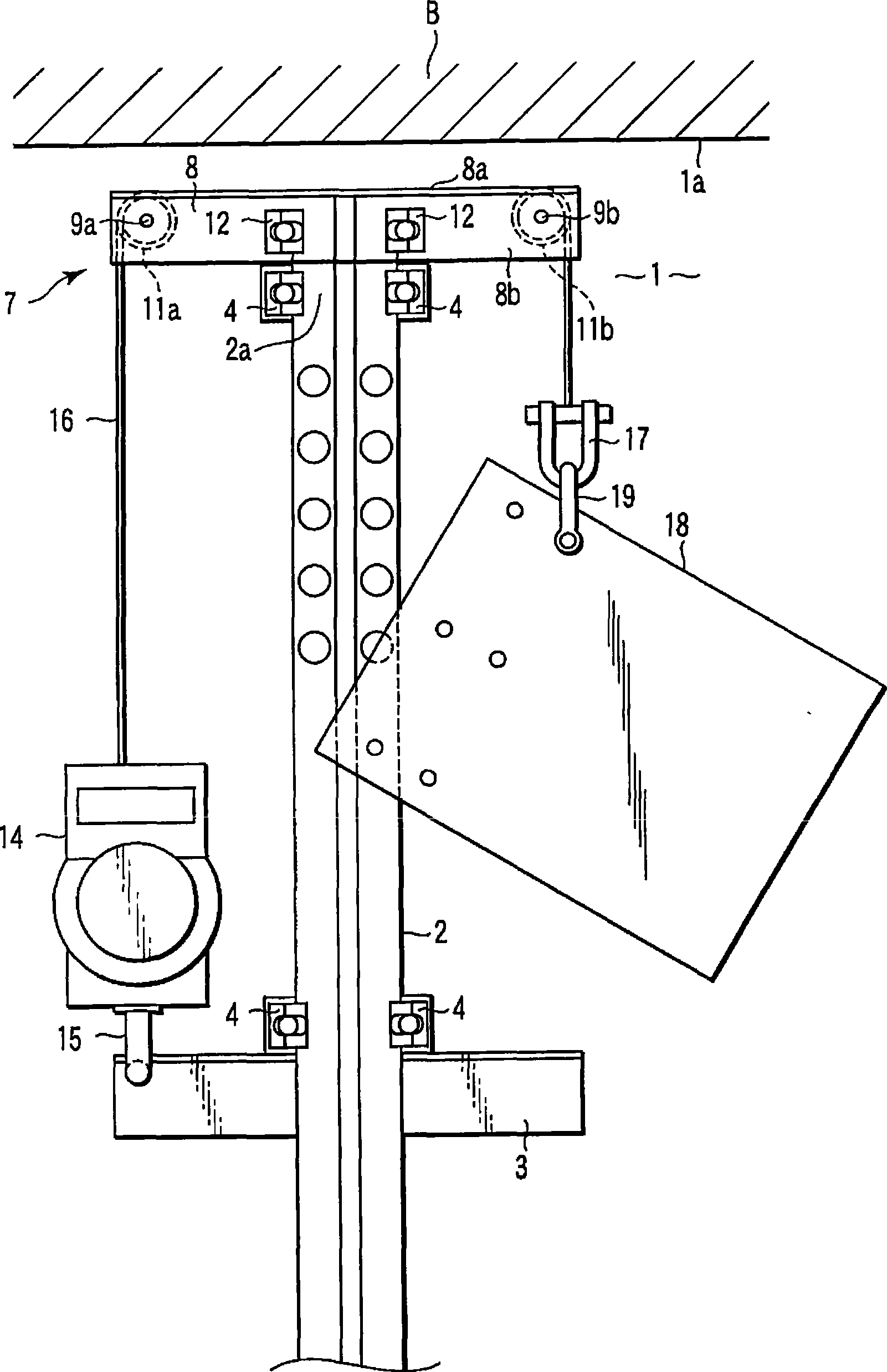

[0027] like figure 1 As shown, a building B as a structure has an elevator passage 1 . A guide rail 2 for guiding the elevator car to go up and down is arranged inside the hoistway 1 . The guide rail 2 is erected vertically along the lifting passage 1. A bracket 3 is fixed on the wall of the lifting passage 1 , and the guide rail 2 is supported on the bracket 3 through a plurality of rail clamps 4 .

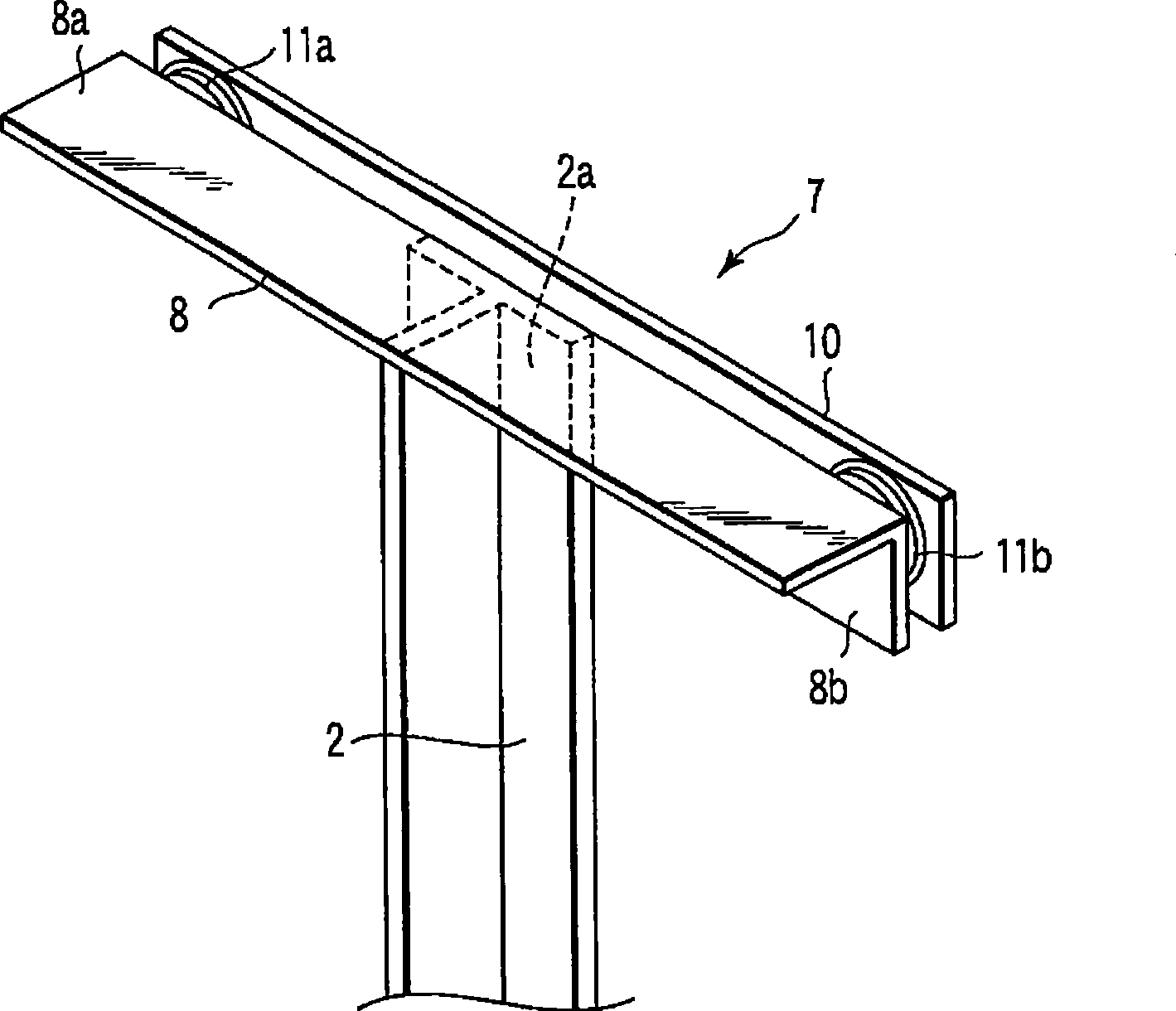

[0028] The top 2 a of the guide rail 2 is close to the ceiling surface 1 a of the lift passage 1 . A pulley device 7 is mounted on the top 2 a of the guide rail 2 . The pulley unit 7 has a first support plate 8, a second support plate 10, and a pair of pulleys 11a, 11b.

[0029] like figure 2 As shown, the first support plate 8 extends perpendicularly to the guide rail 2 in the horizontal direction. The first support plate 8 is made of, for example, an angle steel having an L-shaped cross section having a horizontal plate 8 a and a vertical plate 8 b. The second support p...

no. 3 approach

[0056] According to the third embodiment of the present invention, the lateral movement of the tether part 18 is restricted by the guide member 35 which moves along the guide rail 2 . Therefore, swinging of the tether member 18 when the tether member 18 is pulled up along the lifting passage 1 can be suppressed. In this way, the tether member 18 can be hoisted safely to the vicinity of the top of the lifting passage 1 in a stable posture.

[0057] Figure 7 A fourth embodiment of the present invention is shown.

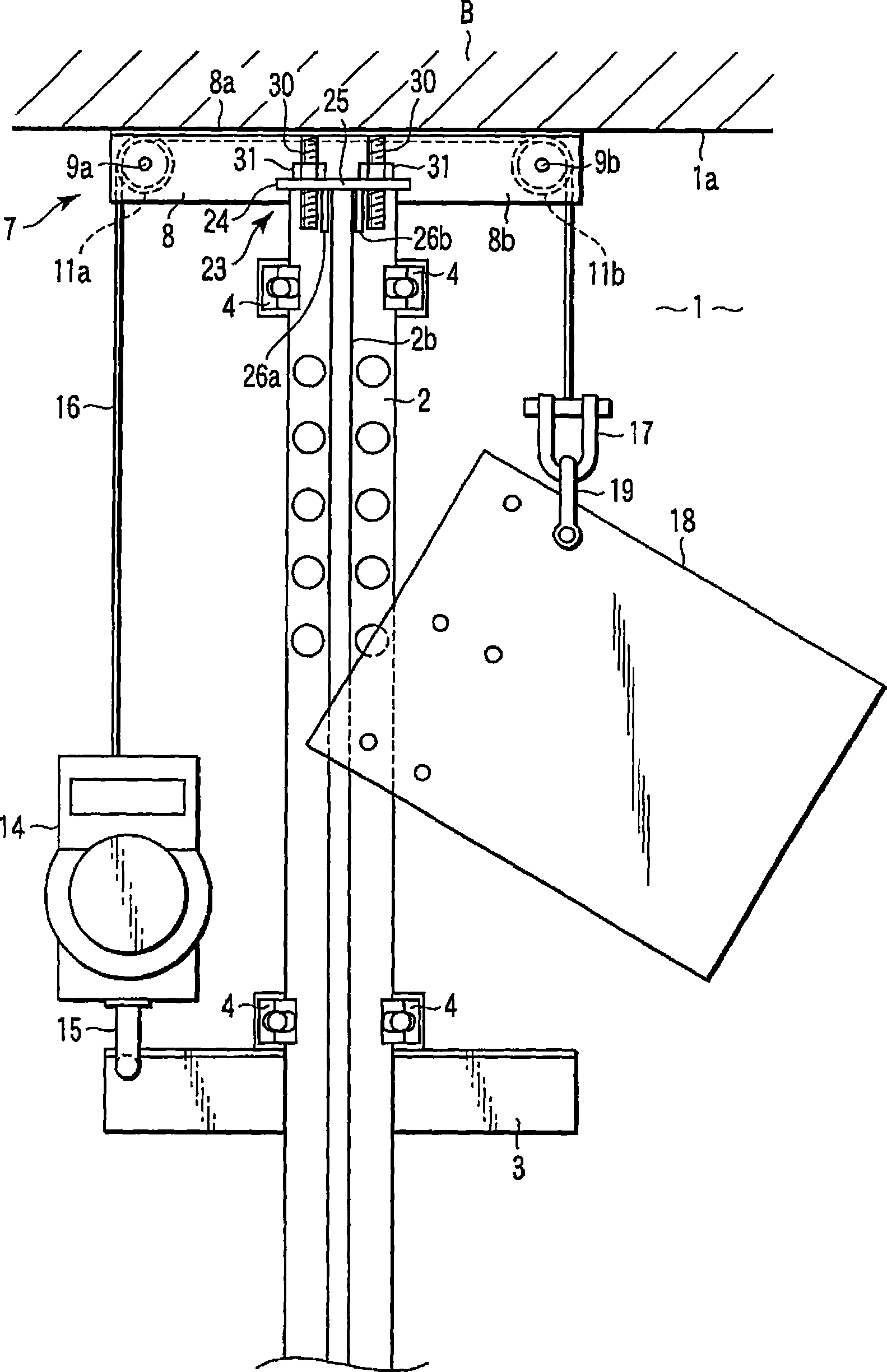

[0058] In the fourth embodiment, the first pulley unit 7 is attached to the top portion 2a of the guide rail 2 by the screw jack 23 similar to the second embodiment. The first pulley device 7 basically has a structure similar to that of the pulley device 7 of the first embodiment.

[0059] Specifically, the first pulley unit 7 has a pulley 11a at one end of the first and second support plates 8,10. The pulley 11a is rotatably supported by the first and second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com