Method for preventing dripping and leaking and employed structure thereof

An anti-drip and effective technology, applied in the field of anti-drip, can solve the problems of fatigue wear, seepage, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

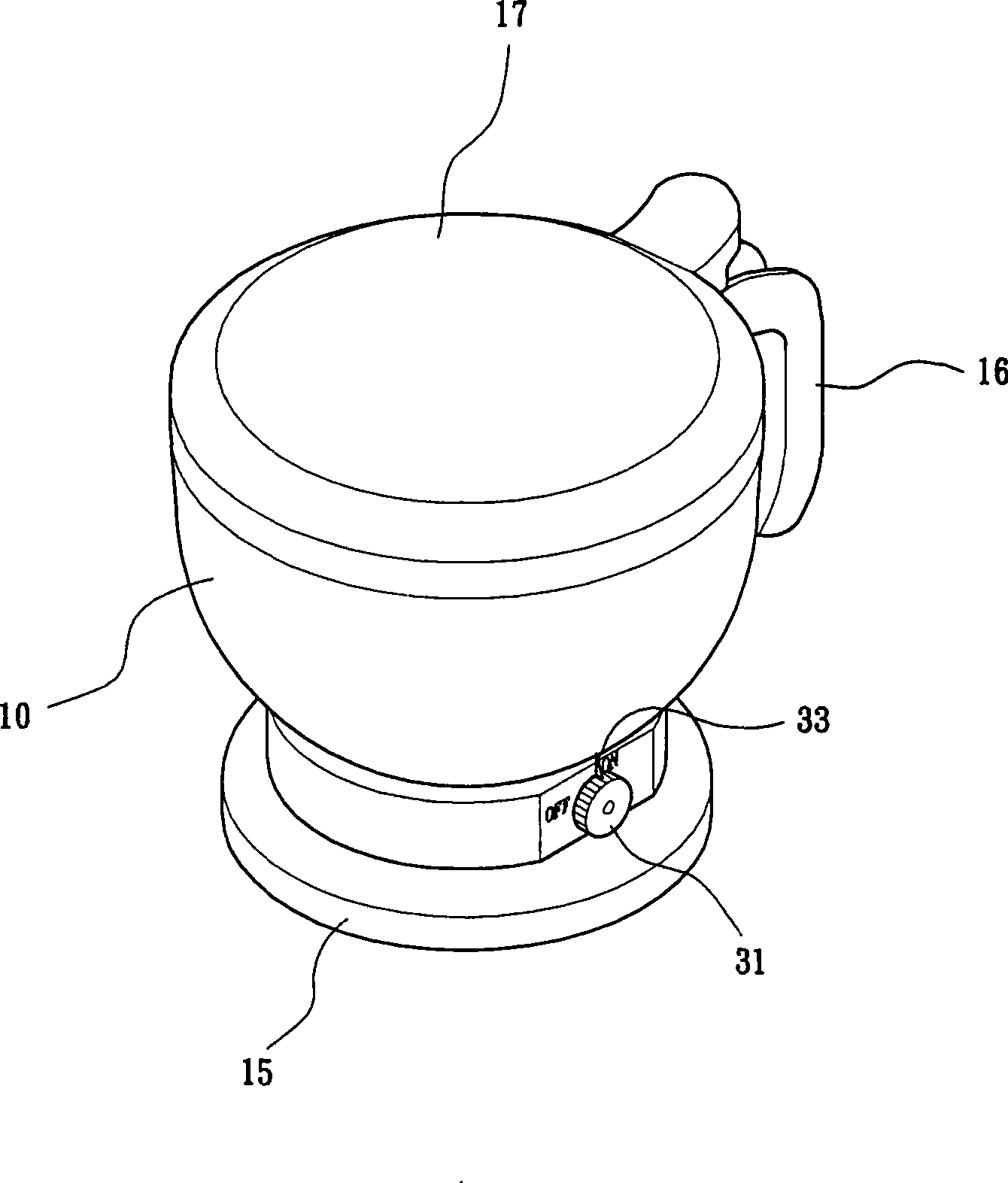

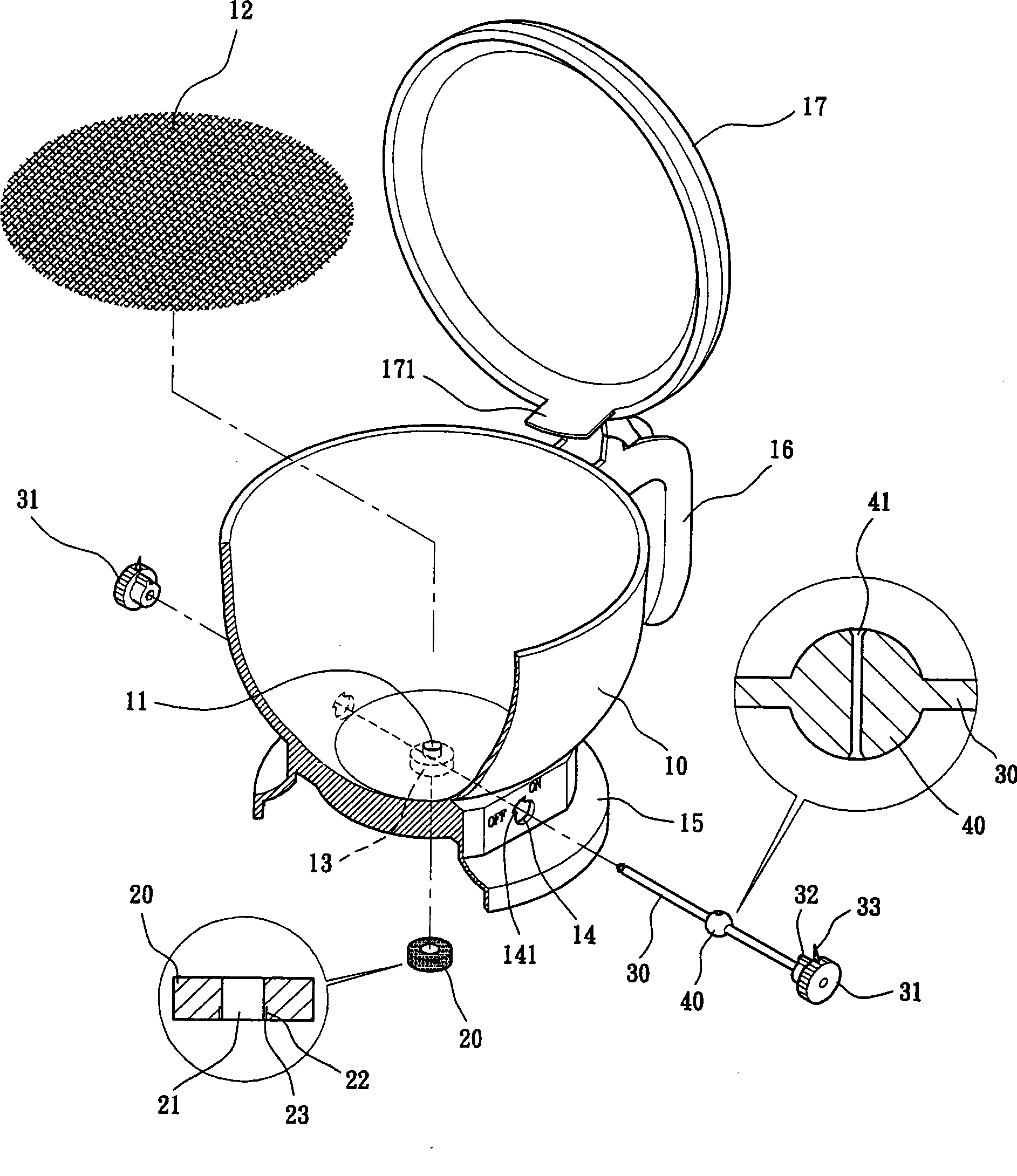

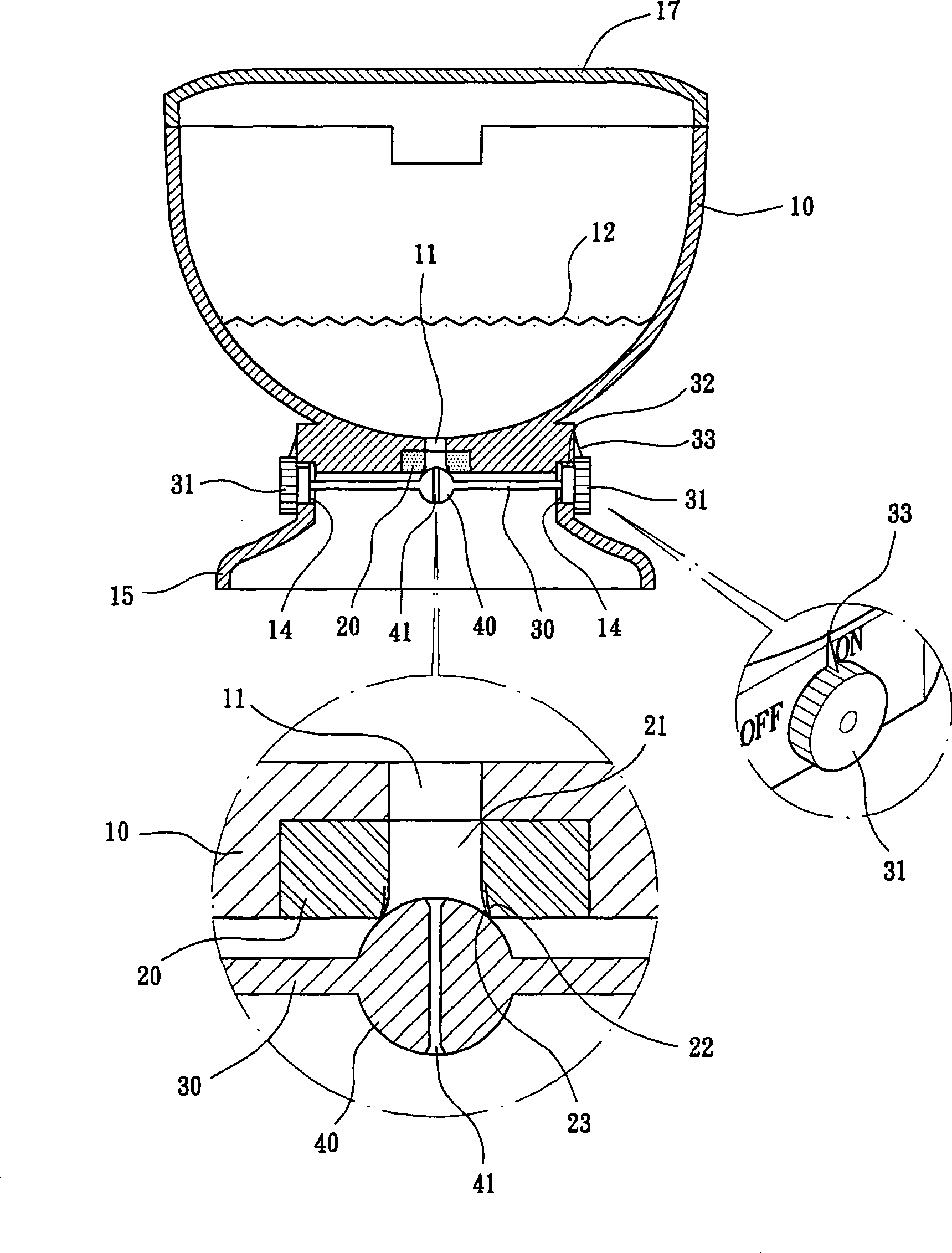

[0042] see figure 1 , figure 2 , image 3 As shown, the anti-drip structure of the present invention includes a container 10, a water stop body 20, a rod body 30, and a blocking body 40; The blocking body 40 is pressed tightly against the water-stopping body 20, thereby having the effect of completely preventing water leakage. The following will explain in detail:

[0043] The container 10 can be filled with other infusions such as coffee powder or tea leaves, and a water outlet 11 is provided at the inner bottom; a filter screen 12 is inserted inside the container 10 to filter impurities in the infusion; the water outlet 11 is provided with a groove 13 to hold A water stop 20 is provided; two corresponding perforations 14 are opened under the container 10, so that the two ends of the rod body 30 can be sleeved therein, and a gap 141 with a predetermined radian is opened at the edge of the perforation 14; a protruding wall extends below the container 10 15, so that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com