A prestressed concrete corrugated sheet pile and its preparation method

A corrugated sheet pile and concrete technology, which is applied in molds, reinforced molding, etc., can solve the problems affecting the soil and water retaining effect of sheet piles, corner damage, etc., and achieve the effects of improving water-stopping effect, high production efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

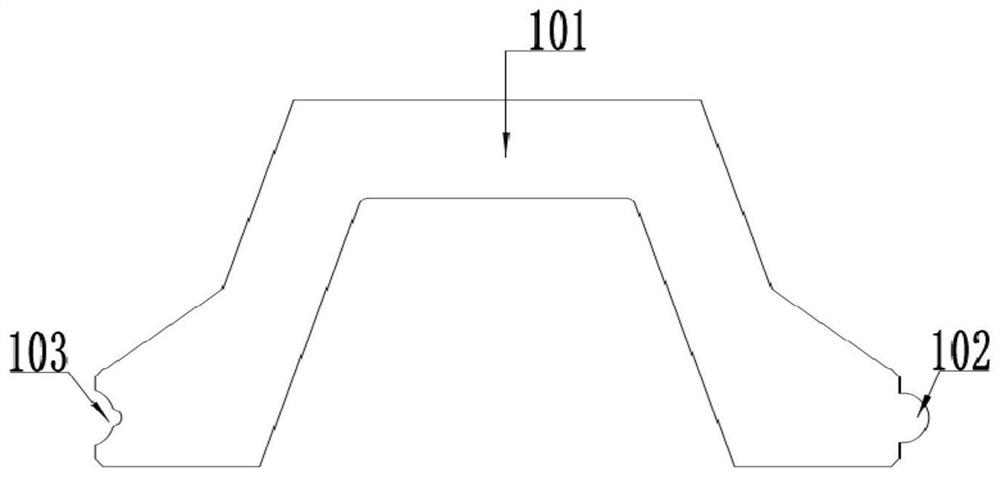

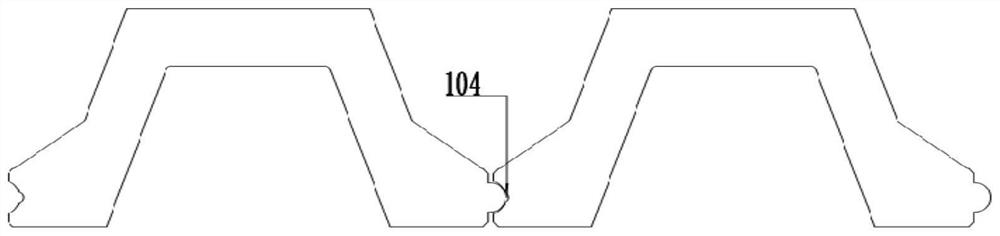

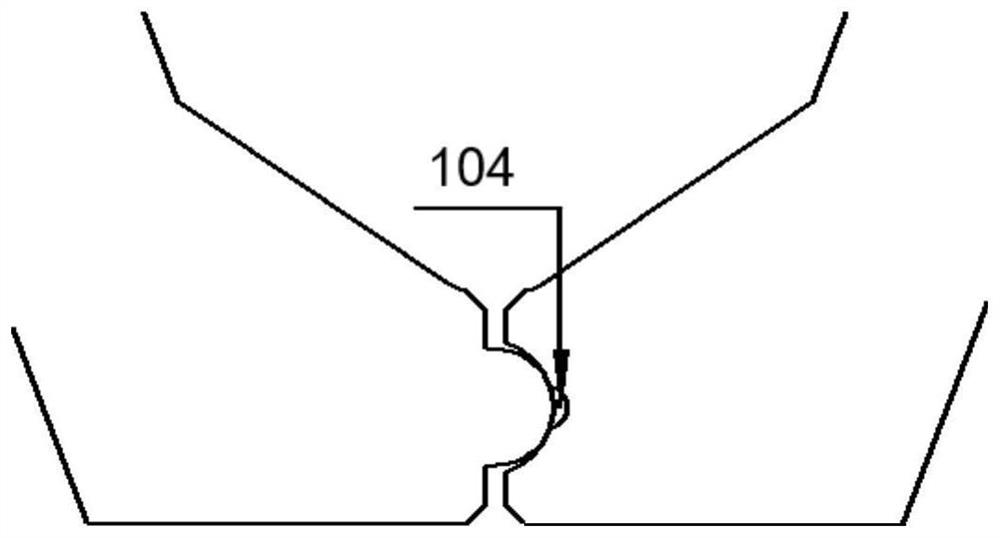

[0047] A specific embodiment of the present invention discloses a prestressed concrete corrugated sheet pile, such as Figure 1 to Figure 2 As shown, it includes a corrugated pile body 101, one side along the length direction of the corrugated pile body 101 is provided with a tenon 102, and the other side is provided with a first groove 103, and the tenon 102 can be inserted into the first recess without gap. In the groove 103 , the cross sections of the tenon 102 and the first groove 103 are both semicircular, and the tenon 102 can rotate in the first groove 103 . The concave surface of the first groove 103 is provided with a second groove 104 along the length direction of the corrugated pile body 101, and the second groove 104 can be filled with water-expandable waterproof glue; the first groove 103 has a second groove 104 A radius is greater than the second radius that the second groove 104 has, such as image 3 As shown, preferably, the second radius is 1 / 20˜1 / 8 of the fi...

Embodiment 2

[0053] This embodiment discloses the preparation method of the prestressed concrete corrugated sheet pile in the first embodiment. The preparation method uses the mold for producing the prestressed concrete corrugated sheet pile to prepare, and includes the following steps: assembling the mold to form a filled steel cage skeleton, prestressing Reinforcement and concrete mold cavity; Install corrugated sheet pile steel cage skeleton and prestressed steel bar in the mold cavity; Utilize tensioning equipment to stretch the prestressed steel bar; Concrete is poured in the mold cavity with prestressed steel bar and Vibration forming; overall maintenance of the cast concrete mold; after the specified time of maintenance, prestressed steel bars are stretched and demoulded to complete the production of prestressed concrete corrugated sheet piles.

[0054] The specific preparation process of the prestressed concrete corrugated sheet pile in this embodiment is as follows:

[0055] Make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com