Connection structure of suspension bracket

A connection structure and support arm technology, which is applied in the field of suspension support arm connection structure, can solve the problems of unsatisfactory requirements and universality, and achieve the effects of improving service life, reducing shear force, and firm and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

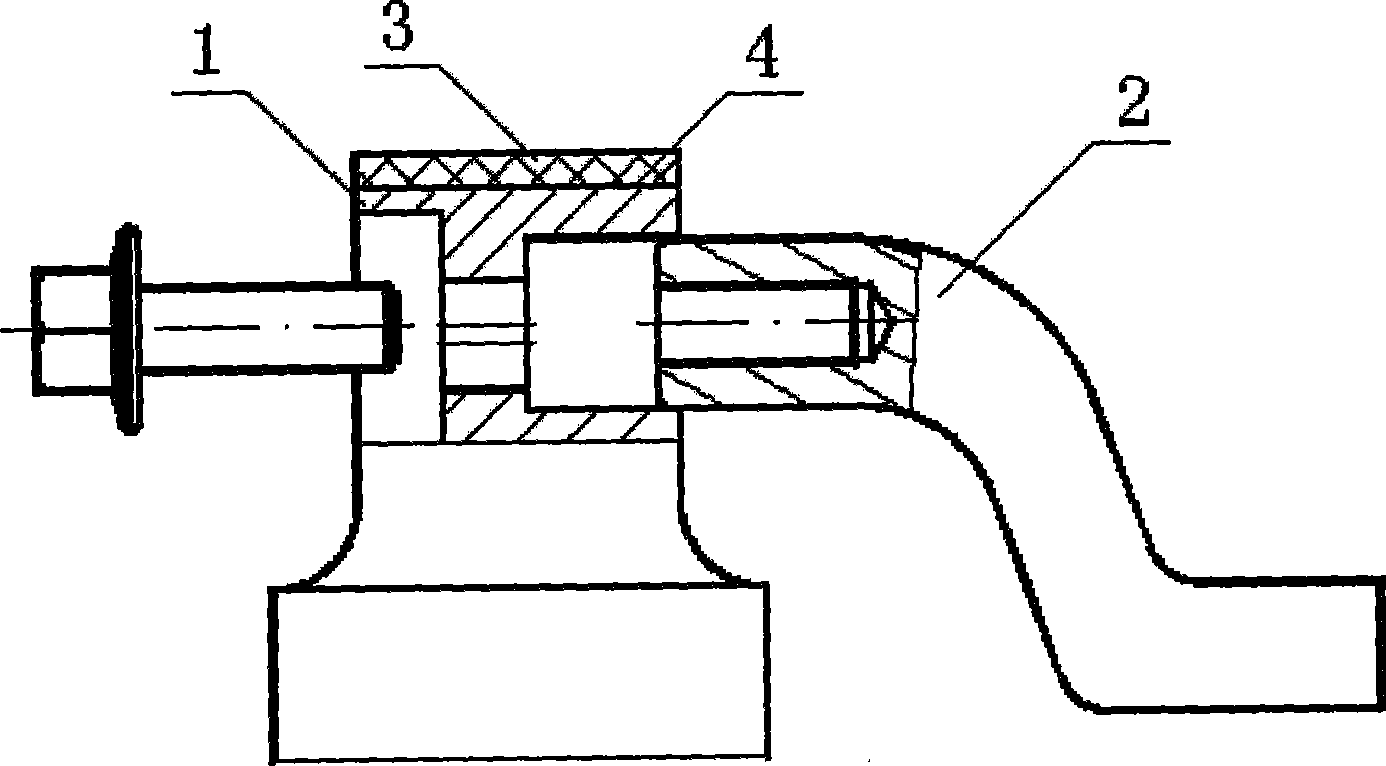

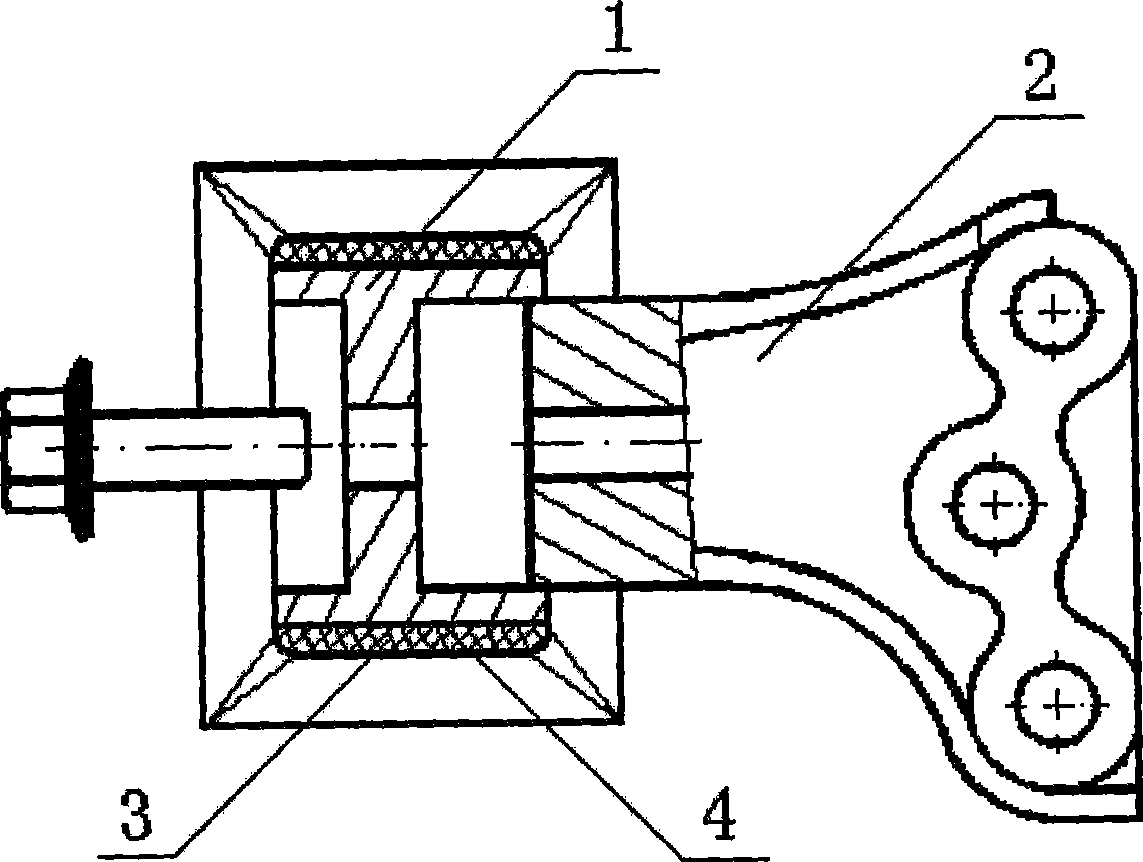

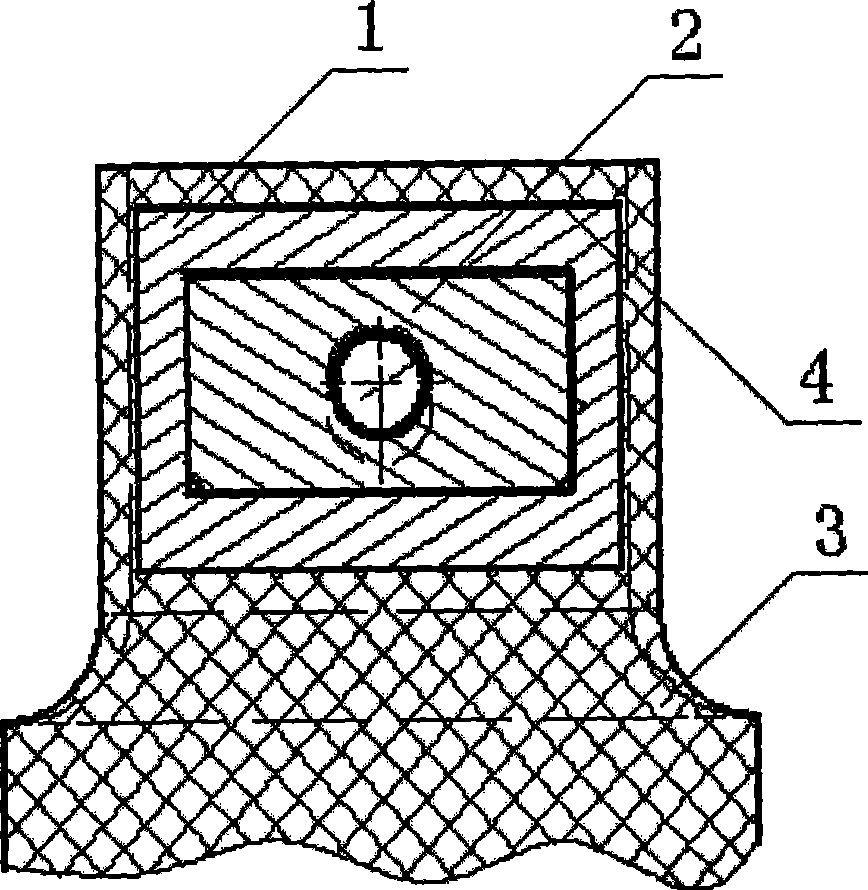

[0019] figure 1 Shown is a schematic structural view of the suspension arm of the present invention, figure 2 Shown is a top view, image 3 Shown is left view. Depend on Figure 1~3 It can be seen from the combination that the connection structure of the suspension support arm includes an inner block, a support arm and a rubber body. The inner block 1 and the support arm 2 are of a split structure, and the inner block 1 is provided with an "I"-shaped stepped through hole. , the support arm 2 is press-fitted to one end of the inner block 1, and it is connected flexibly. The corresponding support arm 2 can be replaced according to different suspension installation points. It is only required to make the assembly size of the support arm 2 and the inner block 1 A uniform size can meet the requirements. The connecting part of the embedded block 1 and the supporting arm 2 is a rectangular structure. A certain amount of interference is reserved on the side of the connecting body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com