Rear vehicle body structure

A body and rear technology, applied in the field of rear body structure, to achieve excellent durability and improved stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]

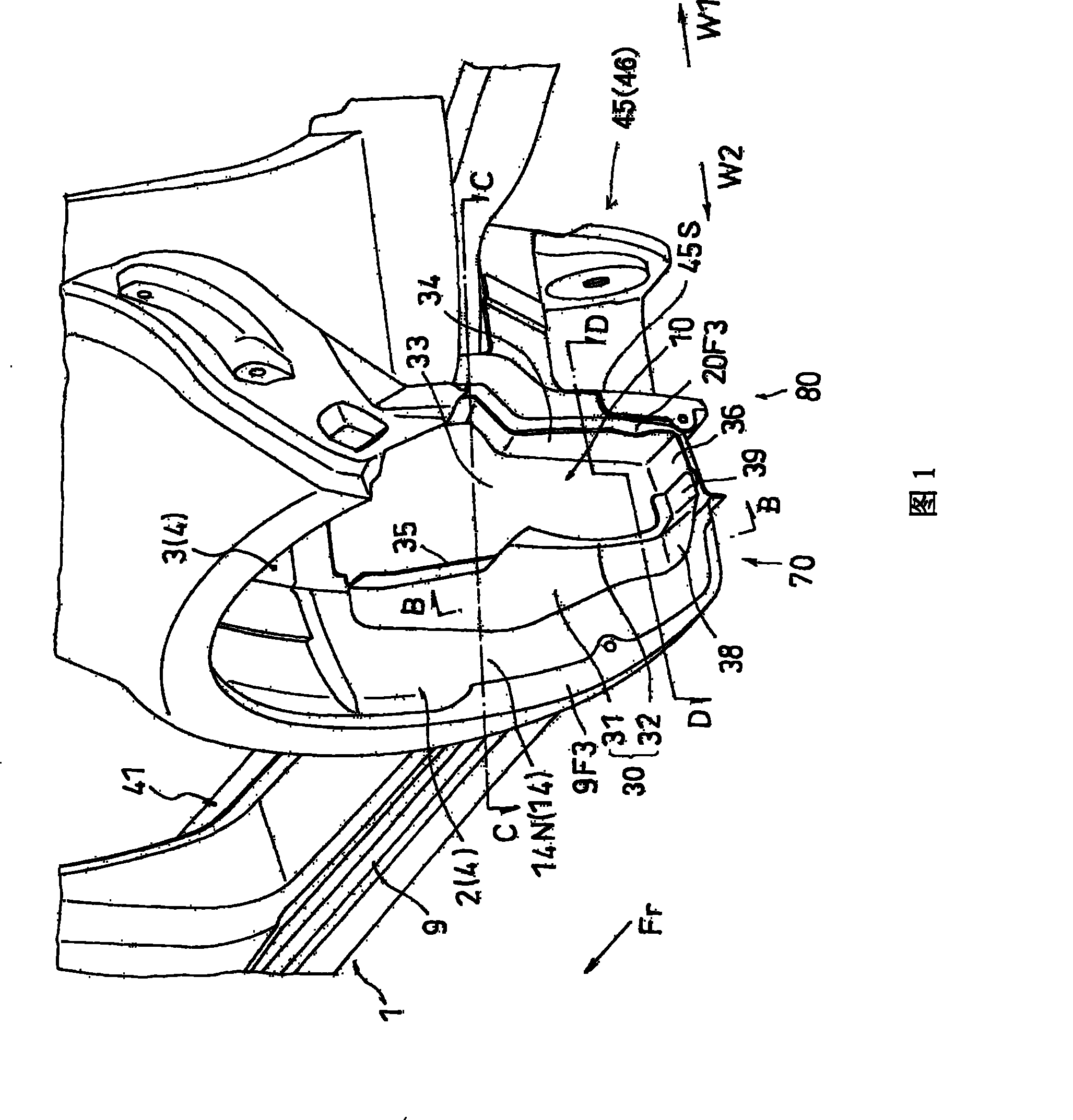

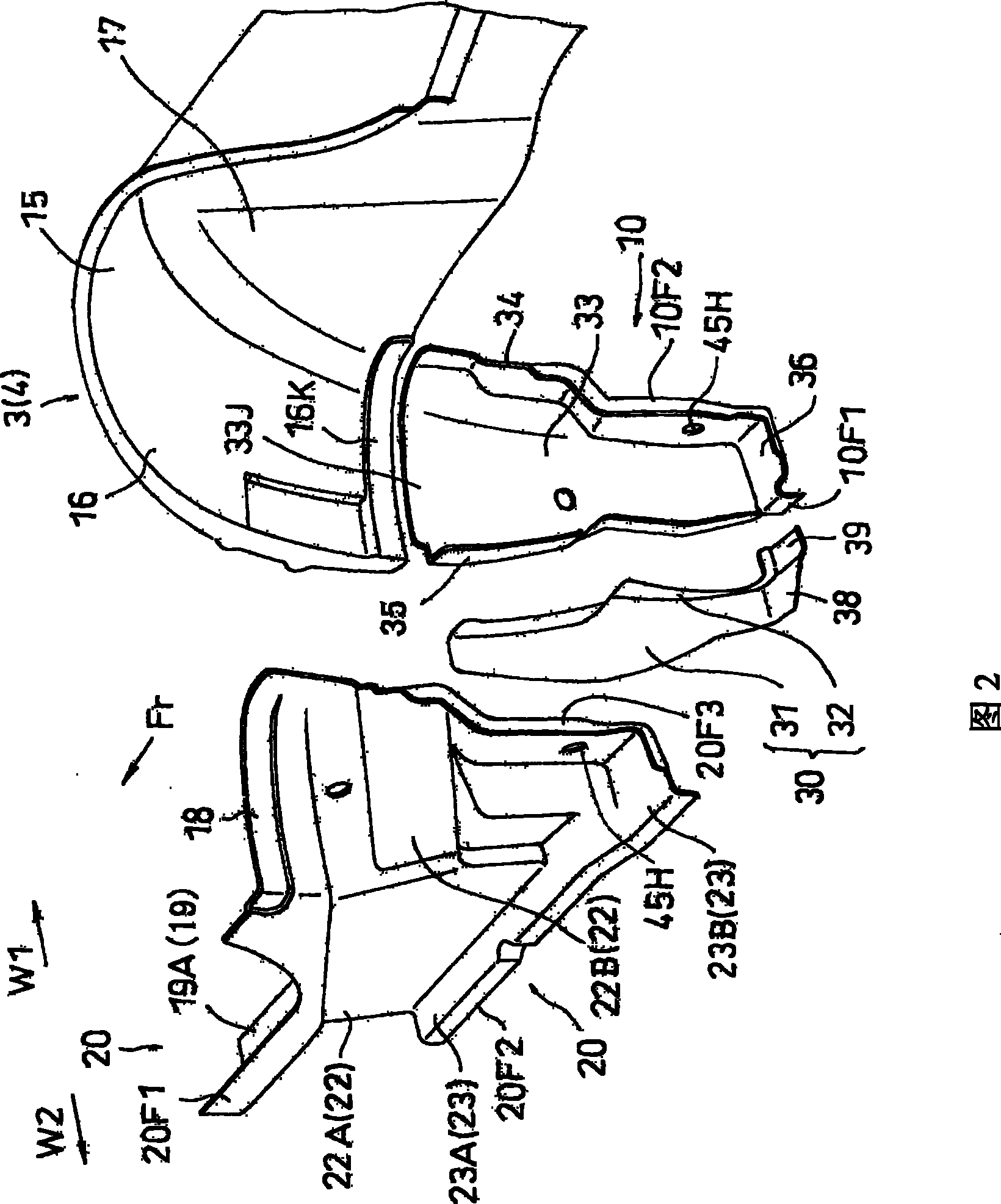

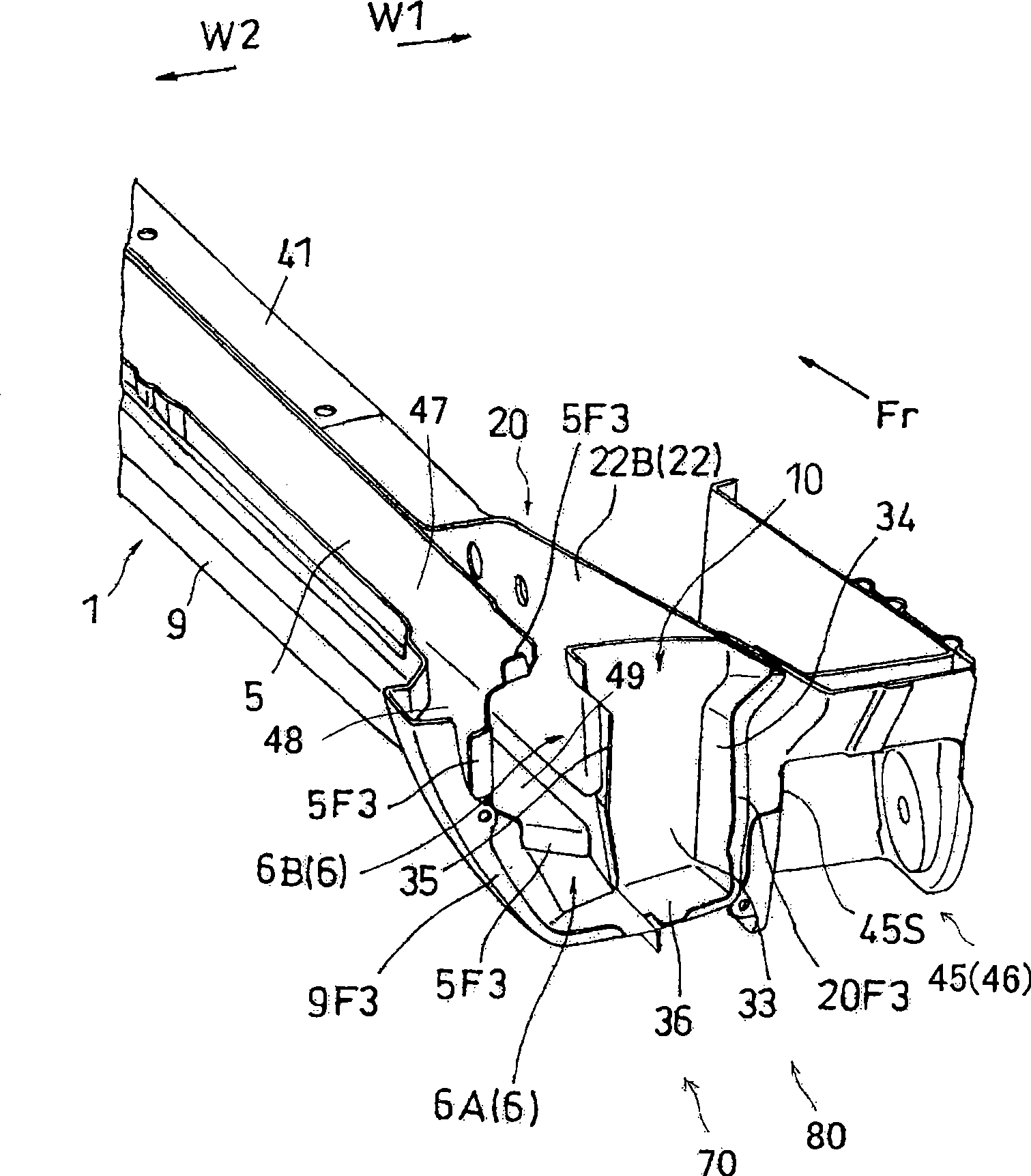

Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Figure 1 to image 3 The rear body structure of an automobile is shown. As shown in the drawings, the wheel house 4 including the wheel house outer panel 2 and the wheel house inner panel 3 is welded to the rear end (hereinafter referred to as the rear end of the vehicle in its longitudinal direction) of the side beam 1 having a closed Section (refer to Figure 12 ) and extend in the longitudinal direction of the vehicle. Side sill reinforcement members 5 that extend in the longitudinal direction of the vehicle and reinforce the side sill 1 are provided therein.

[0018]

In addition, the rear end opening 6 of the side member 1 (refer to image 3) wherein the opening portion 6A corresponding to the outer side W2 in the vehicle width direction is closed by the first front wall portion 14 of the wheel house outer panel 2 , wherein the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com