Dual clutch

A dual-clutch, clutch housing technology, applied to clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

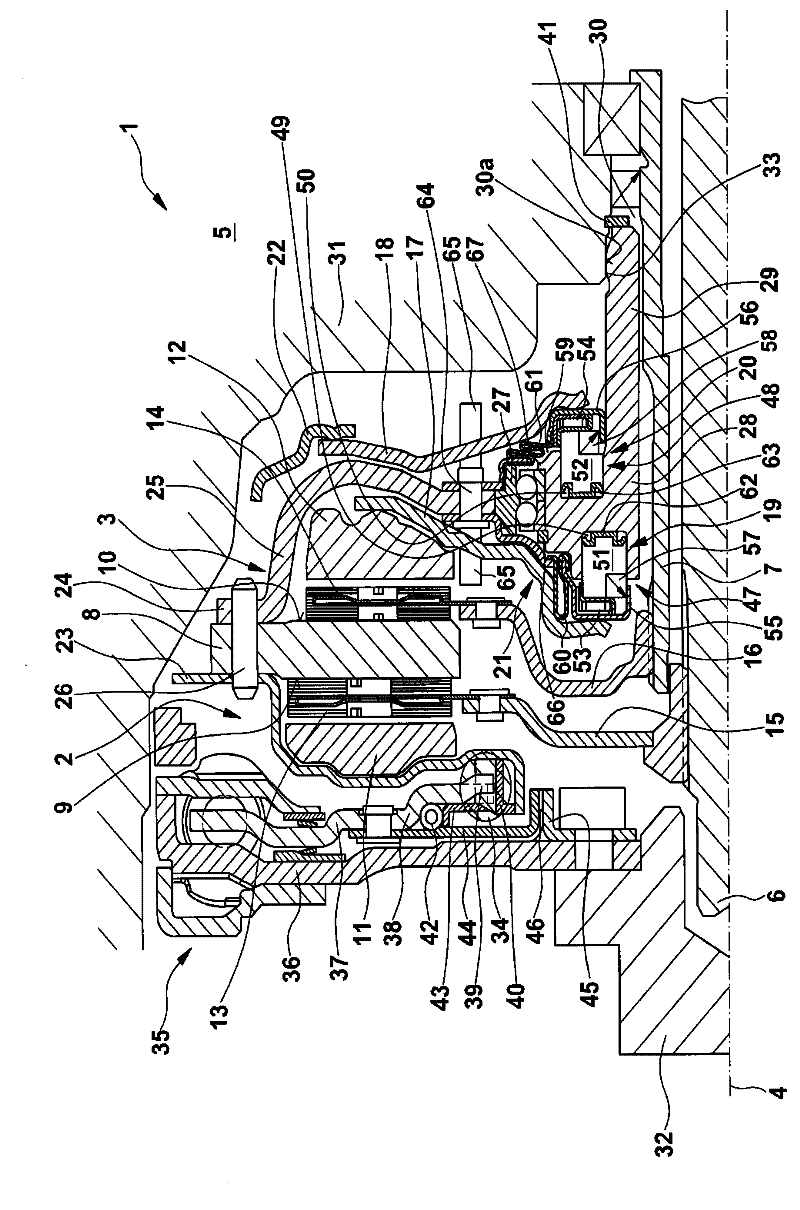

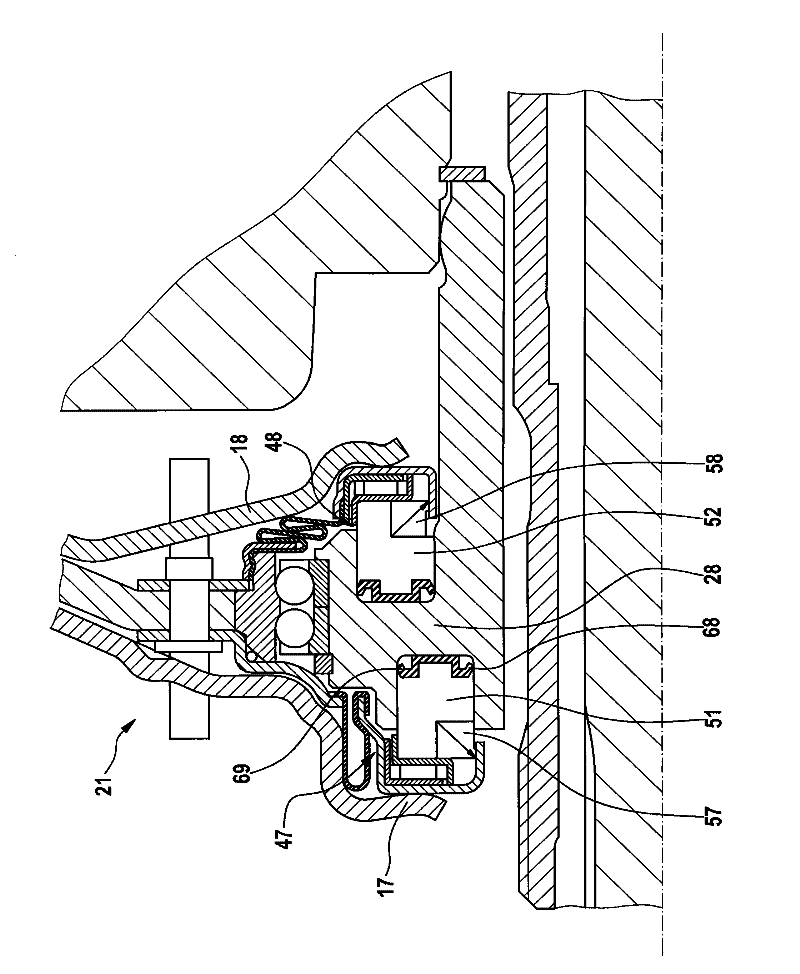

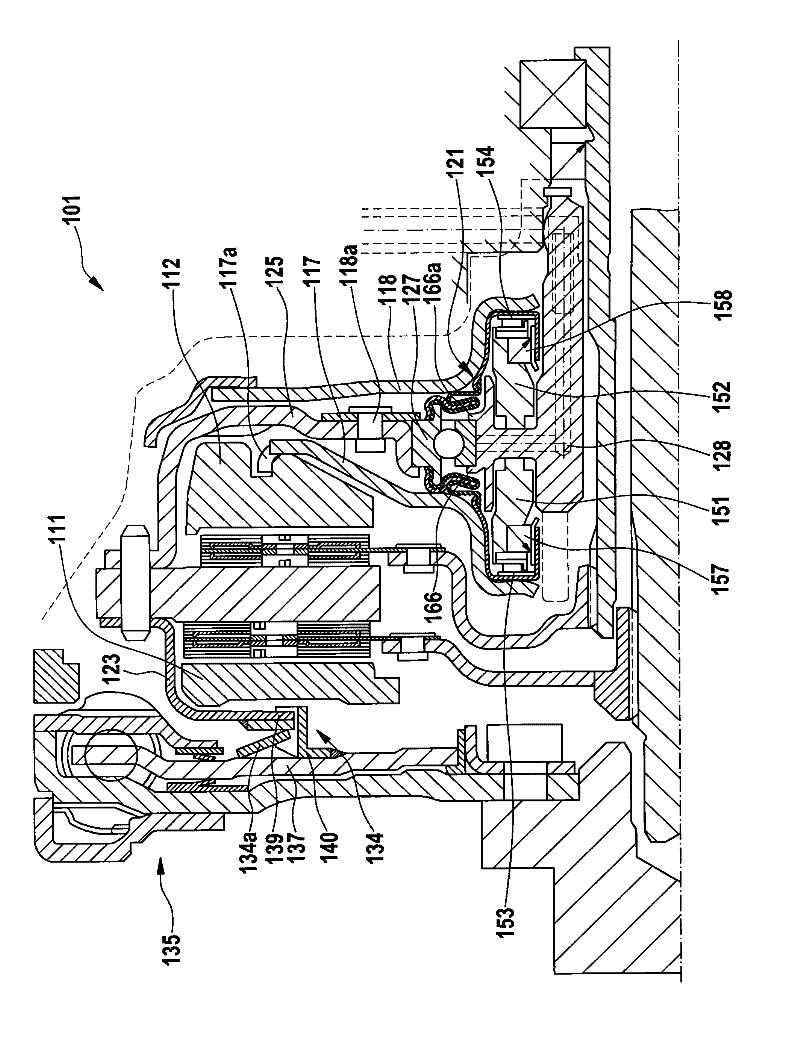

[0049] figure 1 A dual clutch 1 with friction clutches 2 , 3 arranged around a rotational axis 4 of transmission input shafts 6 , 7 of a transmission 5 is shown. The friction clutches 2, 3 are composed of a central pressure plate 8 and pressure plates 11, 12 each movable relative to a friction surface 9, 10, wherein between the friction surfaces 9, 10 and the pressure plates 11, 12 facing these friction surfaces Friction plates 13 , 14 of clutch disks 15 , 16 are arranged between the friction surfaces, and the clutch disks are each non-rotatably connected to a transmission input shaft 6 , 7 , eg toothed. In the illustrated embodiment, the pressure plates 11, 12 are acted upon by the transmission elements 17, 18, which are radially inwardly actuated by the actuating devices 19, 20 of the operating system 21 directly and without the leverage of the transmission elements 17, 18. Towards the movement, so that on the pressure plate 11, 12 by means of the transmission part 17, 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com