Self-floating transportation method of bridge box girder

A transportation method and box girder technology, applied in the field of bridge manufacturing, can solve problems such as high road requirements, difficulty in meeting transportation requirements on ordinary roads and intersections, and unsuitable for long distances

Active Publication Date: 2009-05-20

天津第三市政公路工程有限公司 +1

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Difficulties in land transportation: Car transportation can only be carried out on the premise of dividing the beam into sections, even after segmentation, the requirements for vehicle beams are very high; the requirements for roads are high, and ordinary roads and intersections are difficult to meet the transportation requirements; traffic control is required to cooperate and it is not suitable for long distances; Even if it is transported to the site, how to get off the car and install it is also a problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

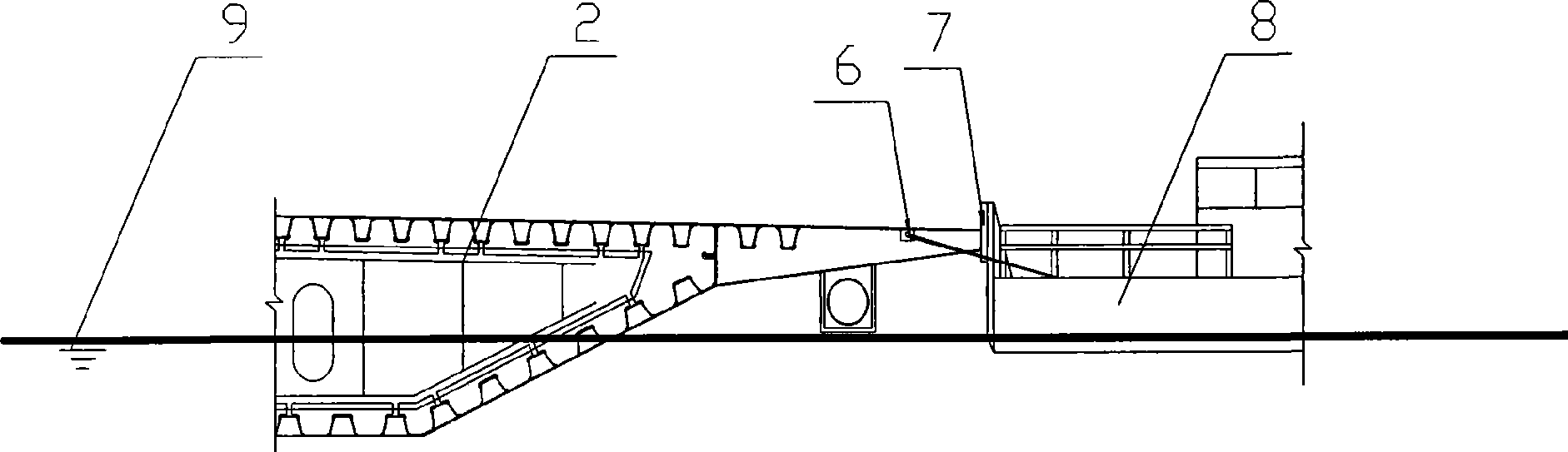

[0026] A method for self-floating transportation of bridge box girders, including water launching and riverway transportation, wherein box girder self-floating transportation adopts the method of box girder sealing, ramp launching, and power boat transportation of self-floating box girders.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

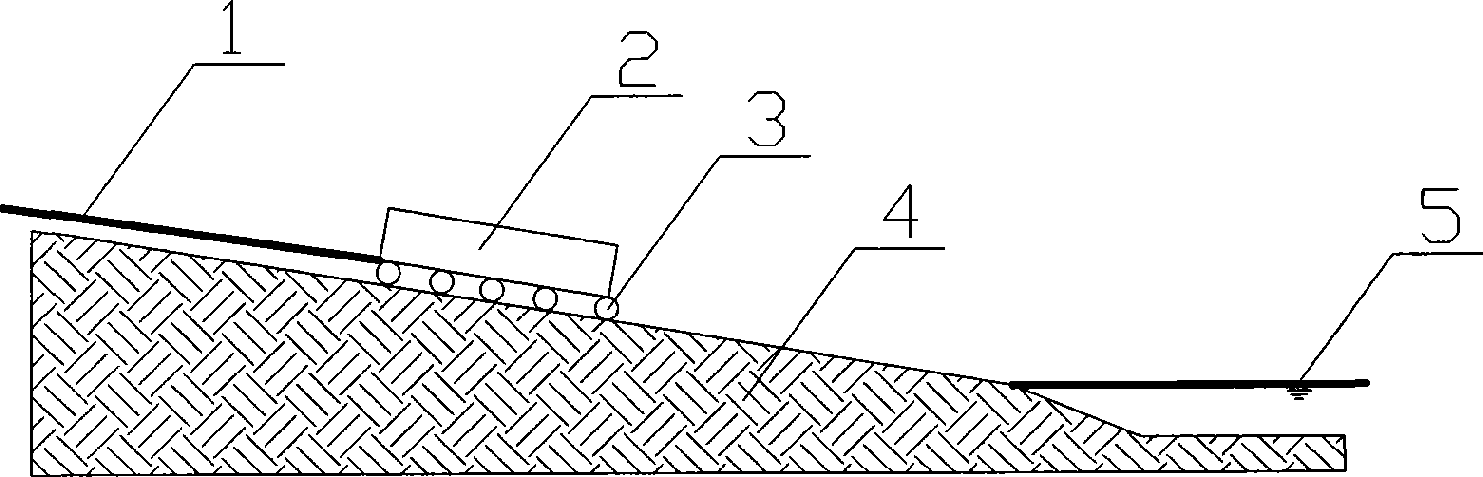

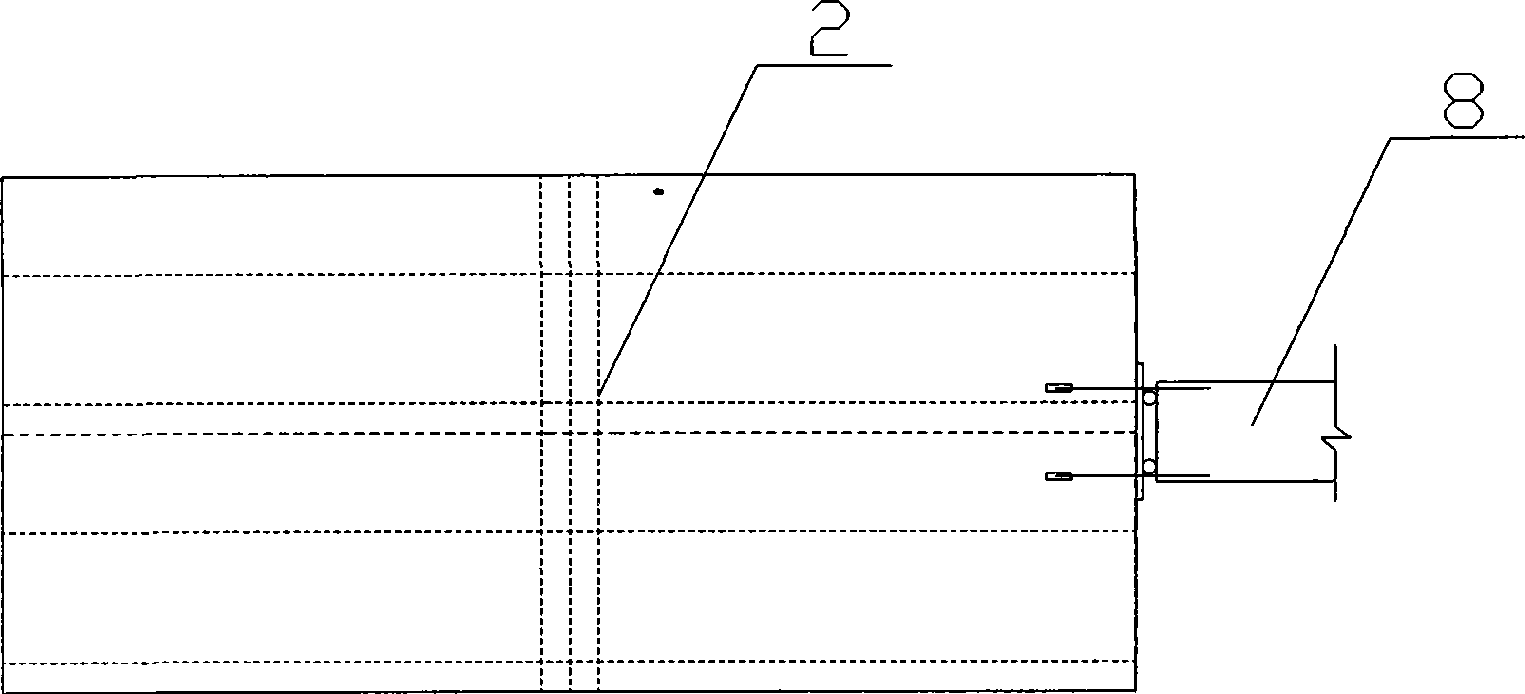

The invention relates to a self-floating transportation method of a bridge box girder, belonging to the field of bridge manufacturing technology. The transportation method comprises the steps of launching and riverway transportation, and is characterized in that the self-floating transportation of the box girder adopts box girder sealing, ramp launching and a method for transporting the self-floating box girder by a power boat; the box girder sealing adopts a steel plate for hole-sealing welding, the steel plate is used for seal-welding a hole and an opening on a diaphragm plate of the box girder; air pockets are distributed at the bottom of the box girder, air charging leads the air pockets to upbear the box girder; the ramp launching adopts a windlass for tightening steel wire ropes so as to control the glissade of the box girder, the air pockets are charged with air alternately, the box girder is moved and launching is carried out along the ramp; and after connection with a self-floating steel box, the power boat carries out transportation in riverways. The method has the advantages of being simple, convenient and practicable, saving time and labor, having low cost and being applicable to the self-floating transportation of steel box girder with large size and weight and the like.

Description

technical field [0001] The invention belongs to the technical field of bridge manufacturing, in particular to a self-floating transportation method for bridge box girders. Background technique [0002] At present, long-span bridges mostly adopt the form of steel structure box girders. The processing and production of steel structure box girder has high requirements on the site, and the available steel structure box girder processing site is often far away from the construction site. Because the processing site occupies a huge area, there is no available site in the bustling urban area. Even if the bridge is located in a newly developed area that is not prosperous, the vast majority of bridge steel box girders cannot Carry out the processing of the box girder at the position. The steel structure box girder has the characteristics of large volume and heavy weight, and the transportation of the steel structure box girder has become one of the key factors restricting the const...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G51/01E01D21/00

Inventor 贾明浩闫学成胡跃陈勇吴冬田少刚

Owner 天津第三市政公路工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com