Tridimensional stretching and perforating net surface

A hole net and three-dimensional technology, which is applied in medical science, bandages, etc., can solve the problems that there is no three-dimensional stretched perforated mesh surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

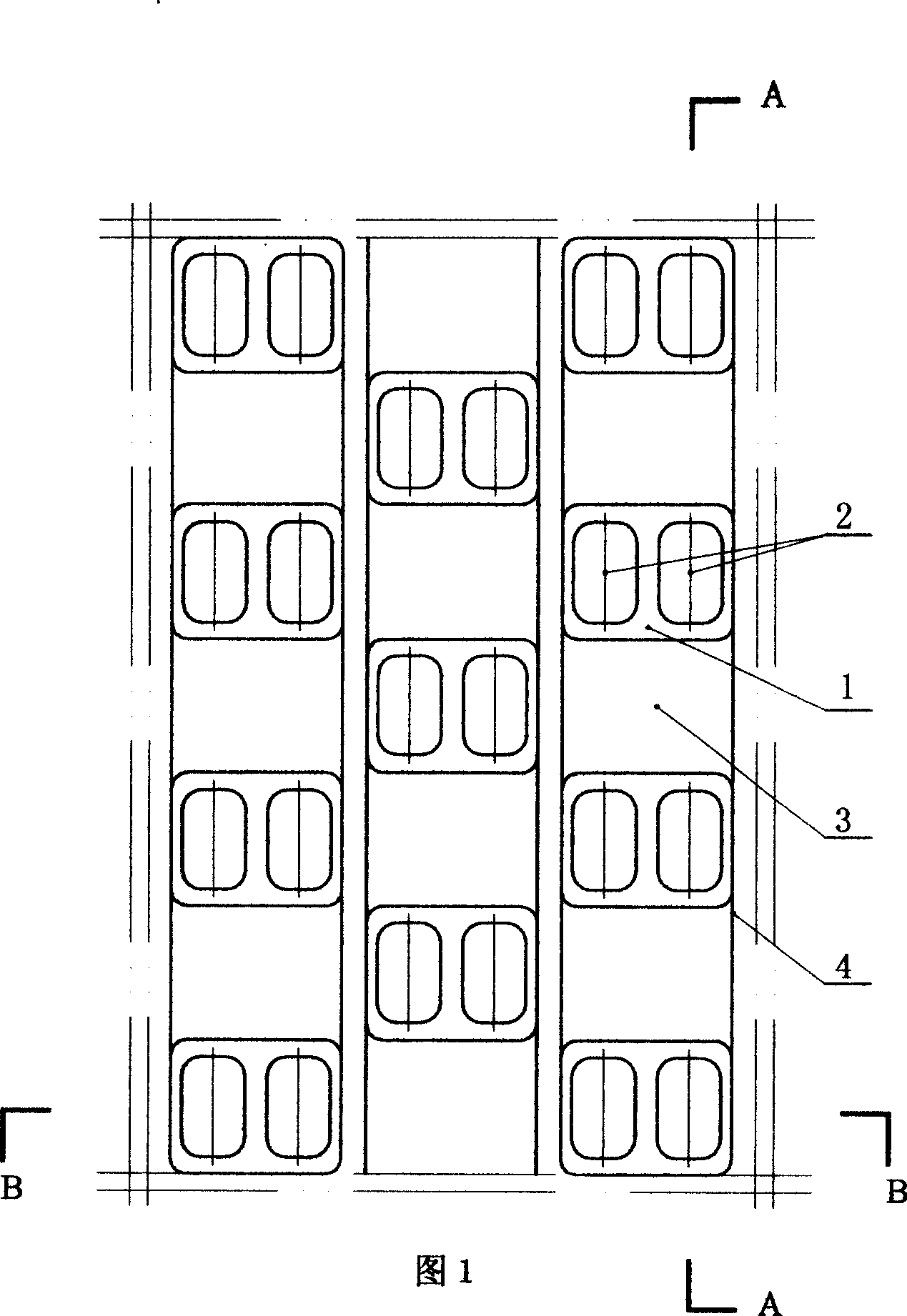

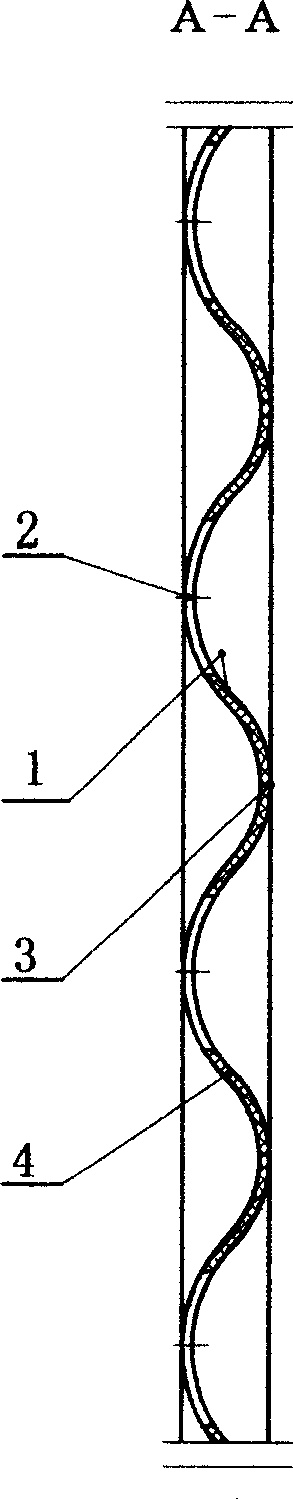

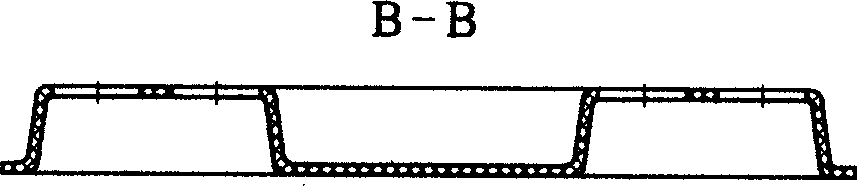

[0010] The present invention is by Fig. 1, figure 2 , image 3 give.

[0011] The present invention is composed of arc-shaped groove 1, combined hole 2, arc-shaped convex top 3 and mesh surface material 4.

[0012] The arc-shaped grooves 1 are arranged at intervals between adjacent columns or in the same row or in a horizontal arrangement at intervals (displaced at intervals in FIG. 1 ).

[0013] The combination hole 2 is N through holes, which are arranged at the bottom of the arc-shaped groove 1. There is a certain distance between the through holes and the through holes. The N through holes are arranged horizontally in the same row, and the number of the through holes is one or two. or N (two in Figure 1).

[0014] The arc-shaped convex top 3 is located in the blank area between the arc-shaped grooves 1. The arc-shaped convex top 3 and the arc-shaped groove 1 are smoothly connected, and the arc-shaped convex top 3 reduces the contact with the human skin. contact area, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com