Self-adapting stabilized contact electric resistance measuring apparatus

A resistance measurement and self-adaptive technology, applied in measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as poor measurement contact, reduce the difficulty of preparation and processing, avoid point contact, and ensure uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The measuring device of the present invention is illustrated by measuring the resistivity of a carbon product for aluminum. The sample is a cylinder with a diameter of 50 mm and a length of 130 mm.

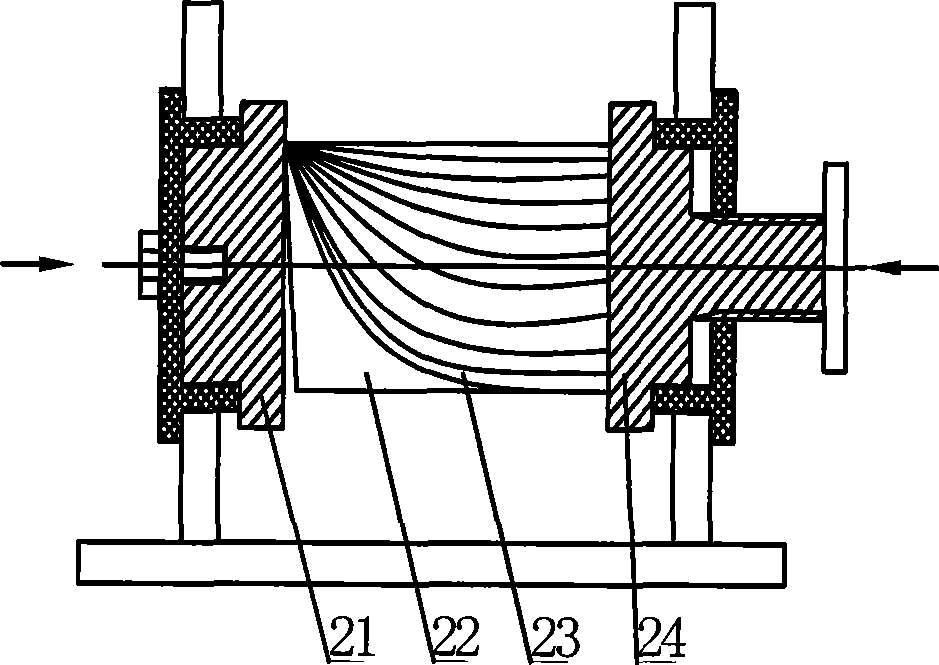

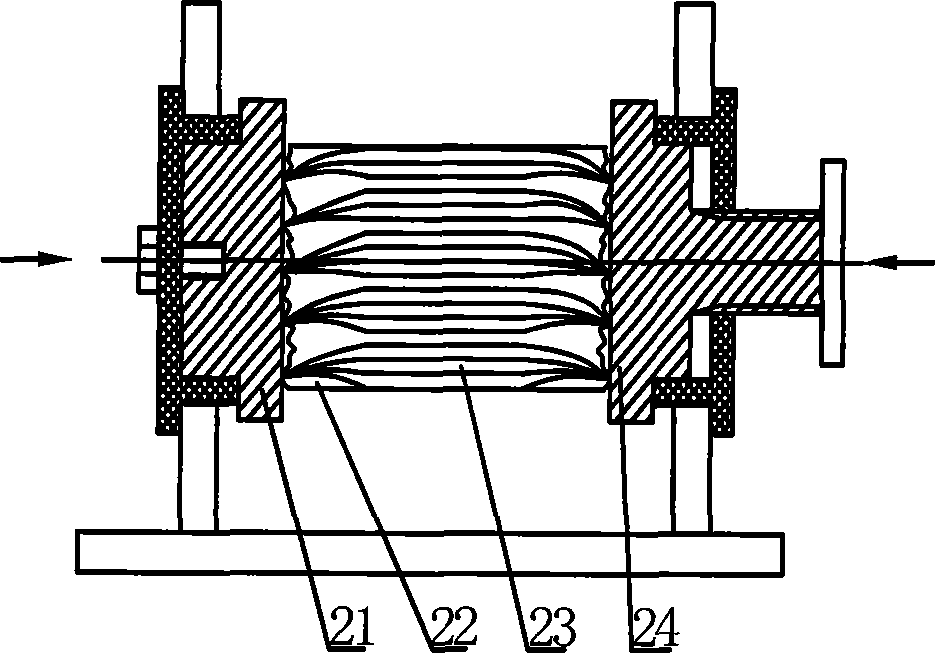

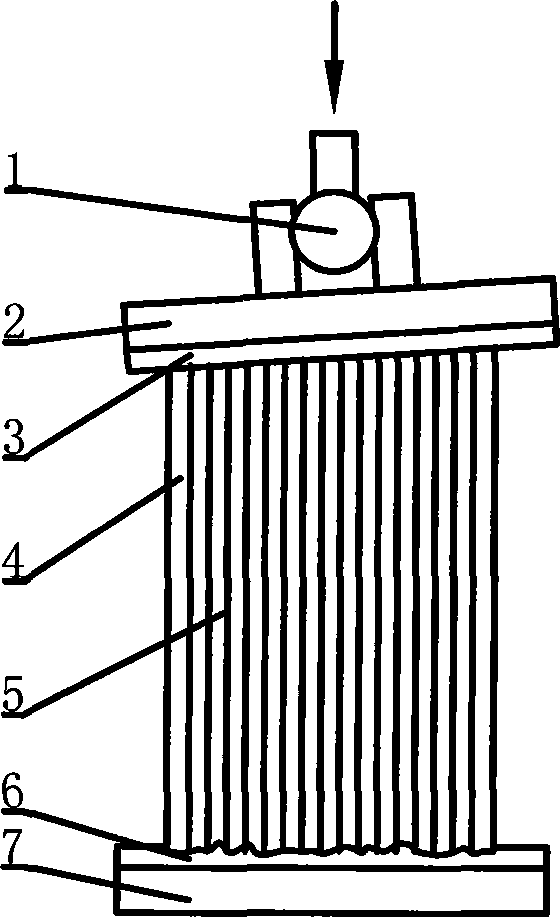

[0023] The measurement is carried out using the measuring device of the present invention. During operation, the upper and lower conductive substrates are in contact with the two end surfaces of the sample, and the pressure drop of the two cross-sections at a certain distance is measured after the current is turned on, and the resistivity of the sample is calculated. image 3 , 4 Shown is a schematic diagram of the structure and operation of an adaptive and stable contact resistance measuring device of the present invention. The device of the present invention includes an upper conductive substrate 2 and a lower conductive substrate 7, and a universal joint is installed on the top of the upper conductive substrate 2. Axis 1. The working surfaces of the upper conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com