LCD module and method for measuring contact electric impedance between circuit boards therein

A liquid crystal display module, contact impedance technology, applied in the measurement of resistance/reactance/impedance, measurement device, measurement of electrical variables, etc., can solve the problems of labor-intensive cost, dependence on labor, inaccurate judgment results, etc., to improve reliability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

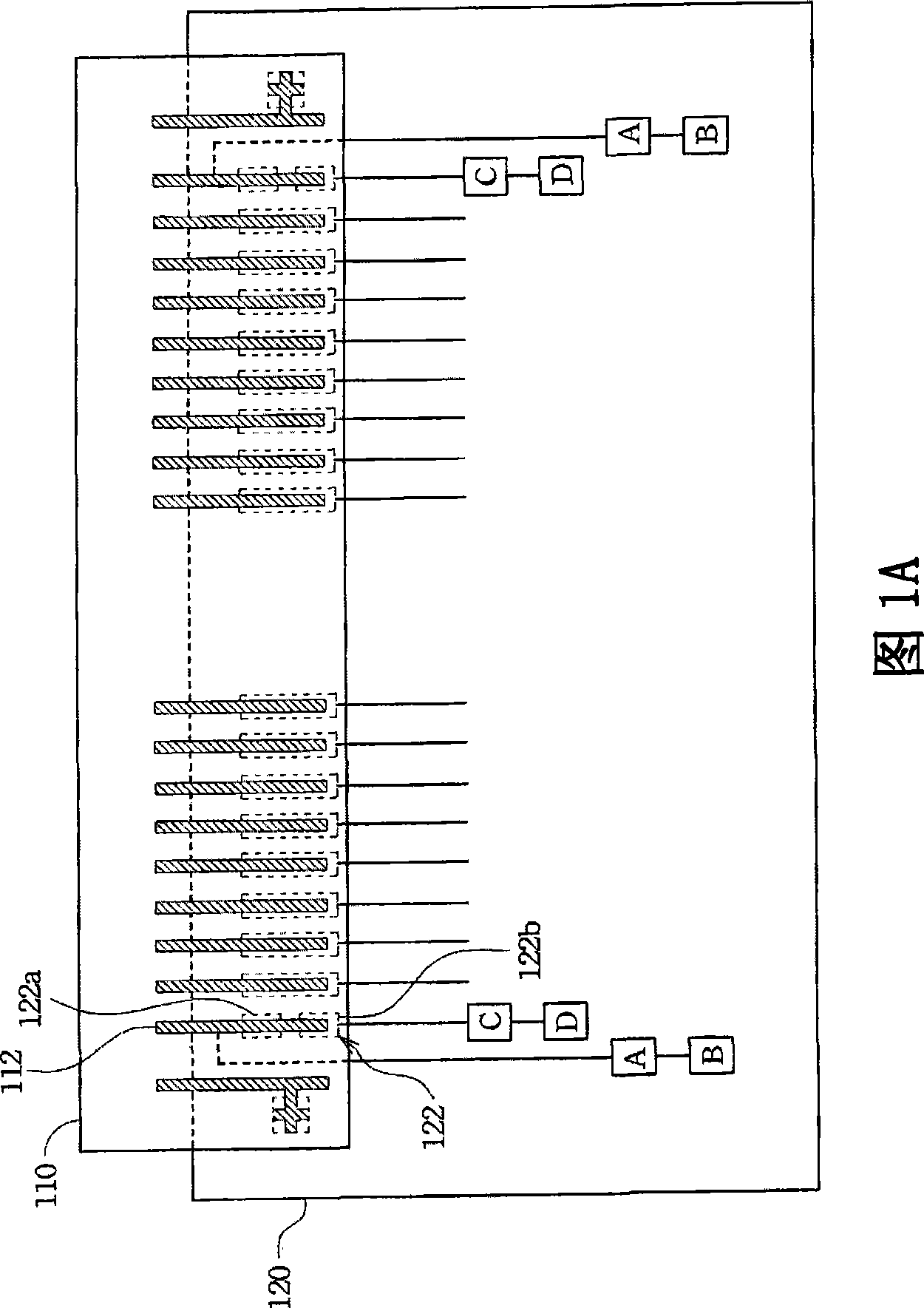

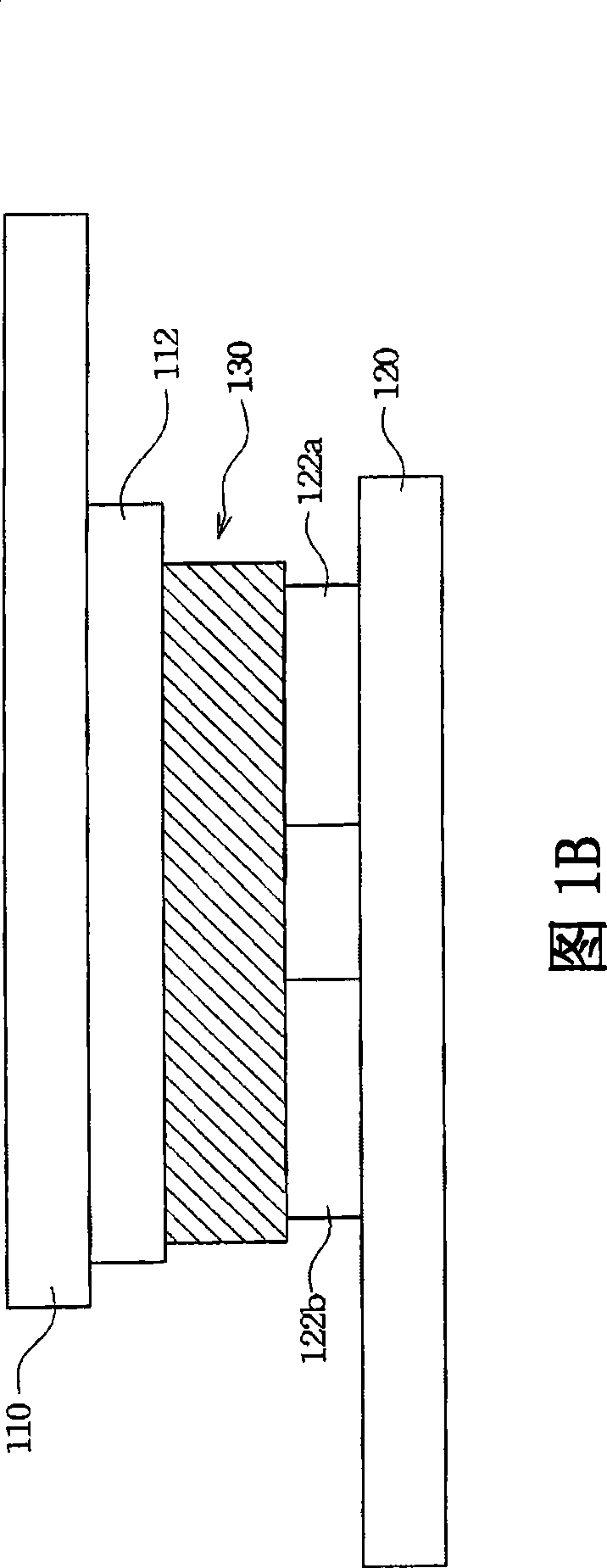

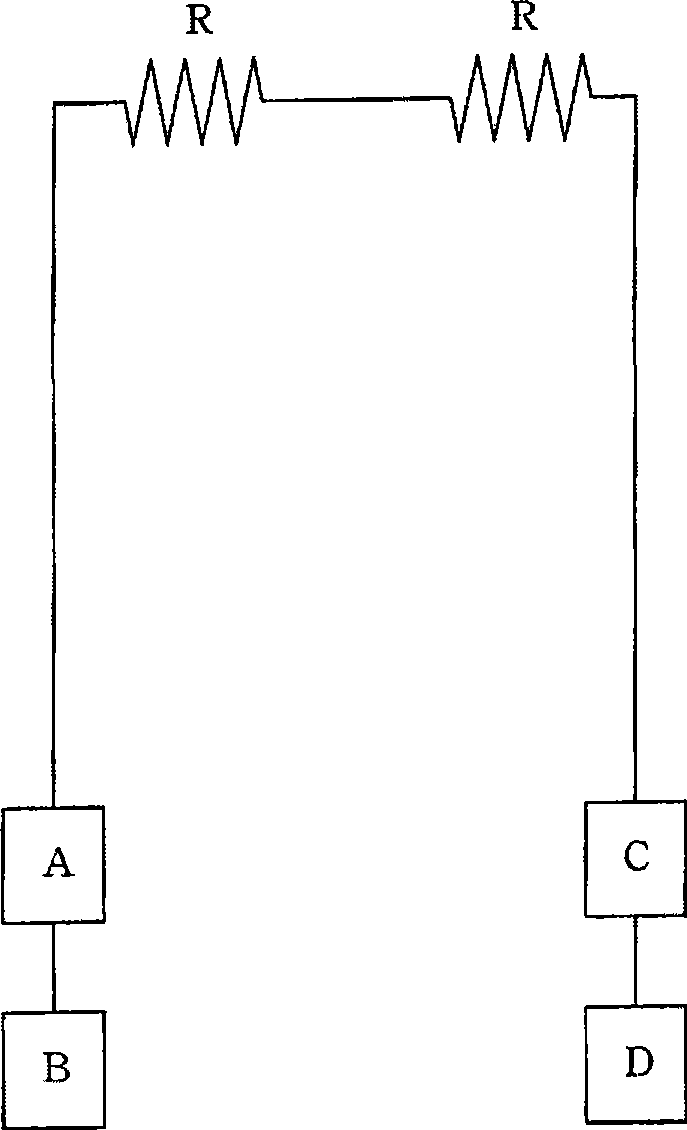

[0030] FIG. 1A is a schematic diagram illustrating the pressing of a circuit board in a liquid crystal display module according to an embodiment of the present invention. The liquid crystal display module includes a flexible circuit board (FPC) 110 and a printed circuit board (PCB) 120. The flexible circuit board 110 is provided with a first wire 112, and the printed circuit board 120 is provided with a second wire 122, and The second wire 122 is electrically connected to the first wire 112. In addition, the printed circuit board 120 may be provided with soldering pads A, B, C, and D, wherein the soldering pad A is electrically connected to the first wire 112, and the soldering pad C is electrically connected to the second wire 122 for supplying with a detection device (such as: A probe or a three-meter or related detection device) is electrically contacted to determine whether the second wire 122 is actually electrically connected to the first wire 112, and the bonding pads B and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com