Outer frame of backlight module unit

A technology of backlight module and outer frame, applied in optics, nonlinear optics, components of lighting devices, etc., can solve the problems of up and down displacement of optical film, increase manufacturing cost, operator fatigue, etc., and achieve easy assembly and The effect of disassembly, improving product quality and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

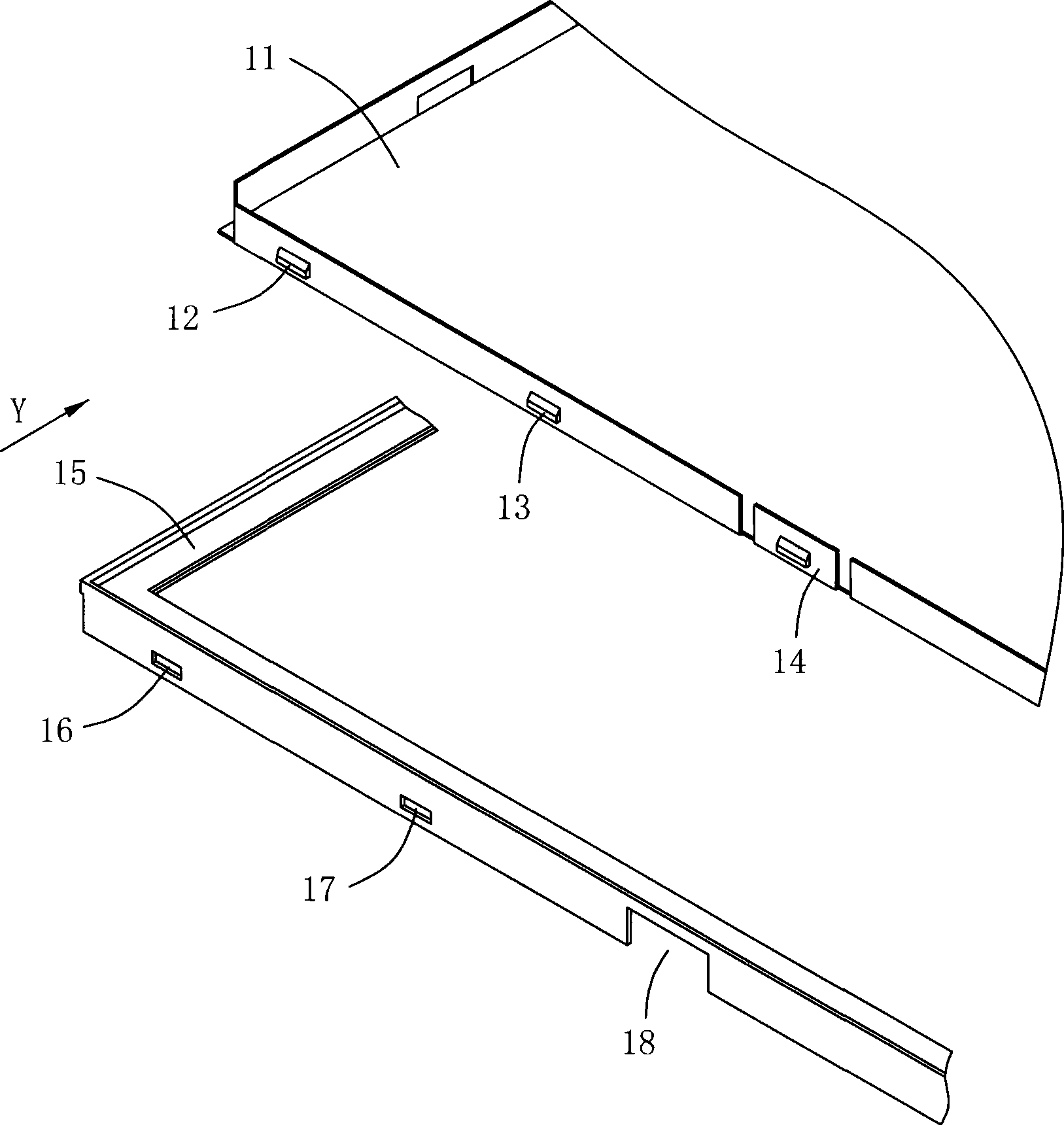

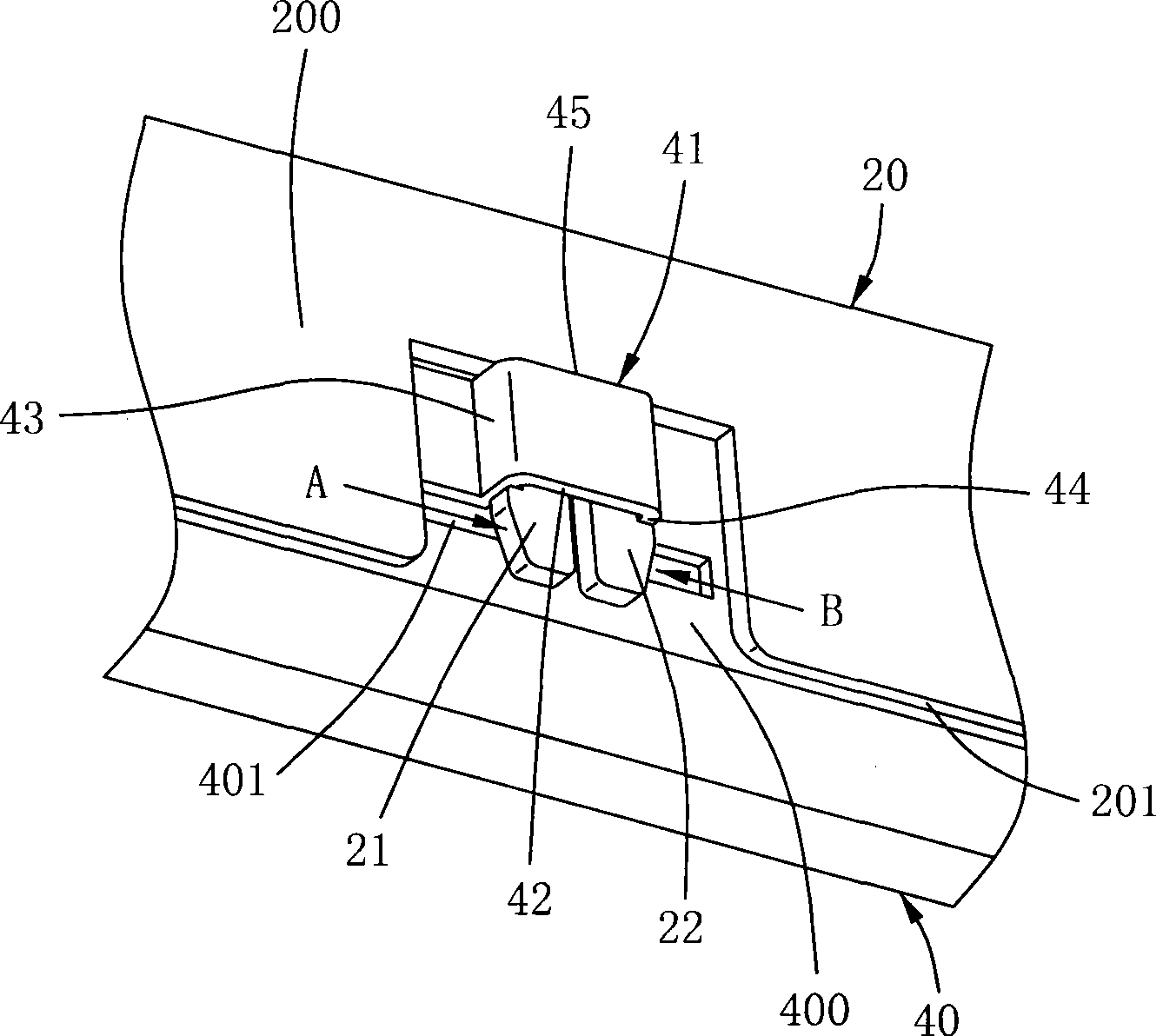

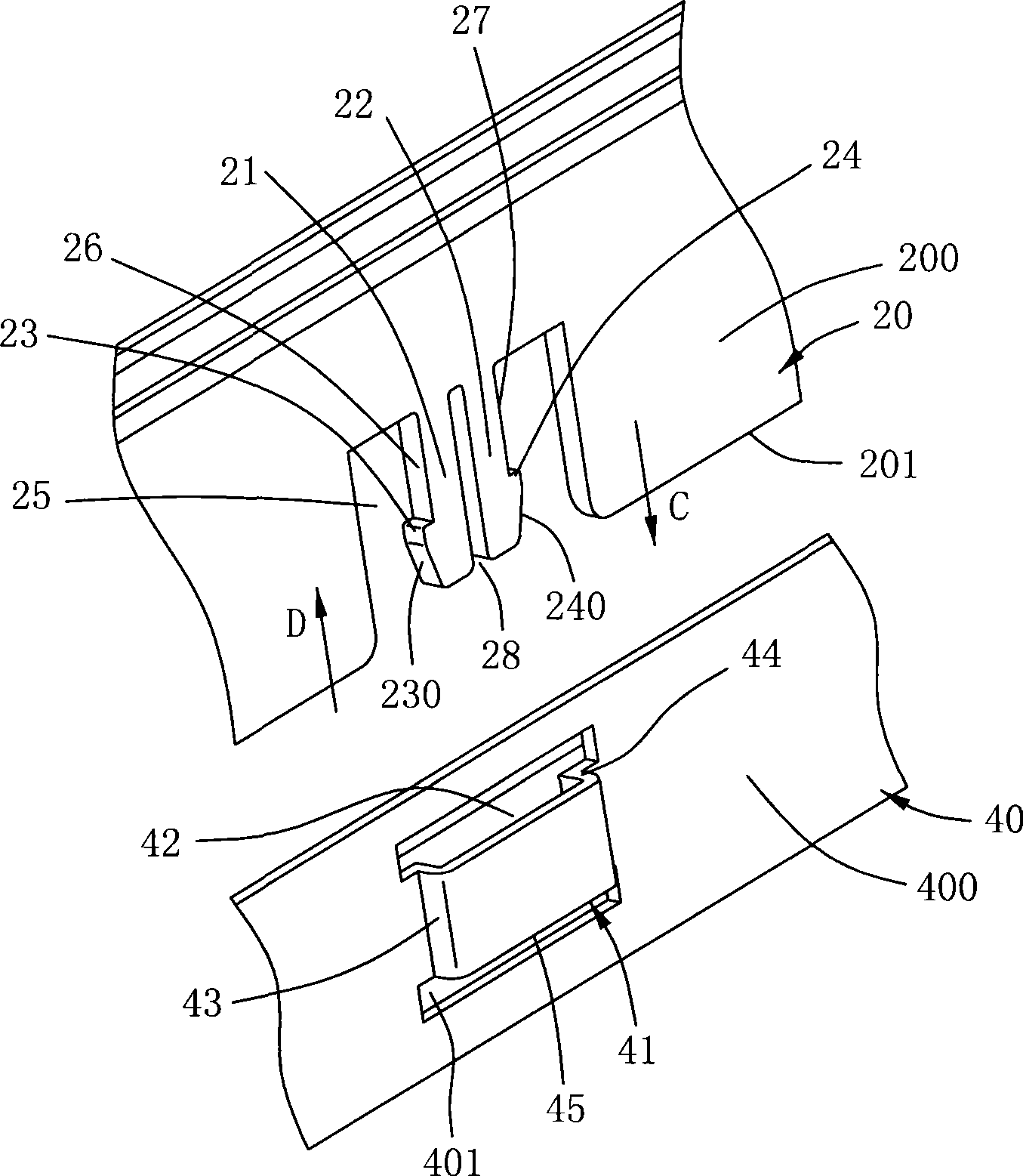

[0016] Please refer to figure 2 , image 3 As shown in FIG. 4 , according to the present invention, an outer frame of a backlight module is provided, which includes a plastic frame (first frame) 20 and a backplane (second frame) 40 . The plastic frame 20 has at least one first hook 21 and one second hook 22, and the backboard 40 has at least one buckle portion 41, the first hook 21 and the second hook 22 can be connected with the buckle portion 41 of the backboard. Interposed and matched with each other to achieve the purpose of fixing the plastic frame 20 and the back plate 40 .

[0017] The plastic frame 20 is made of plastic material. The plastic frame 20 has a first folded edge 200 and at least one firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com