Method and apparatus for improving uniformity of large-area substrates

A large-area, uniform technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problem that the influence of SiN film thickness uniformity and film property uniformity cannot be detected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

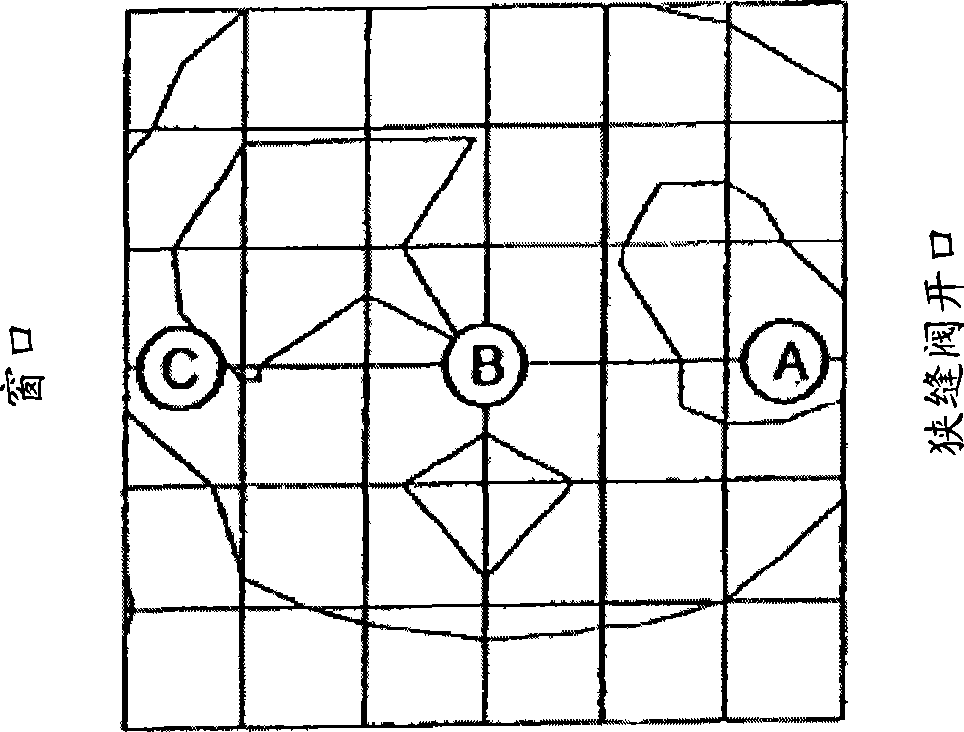

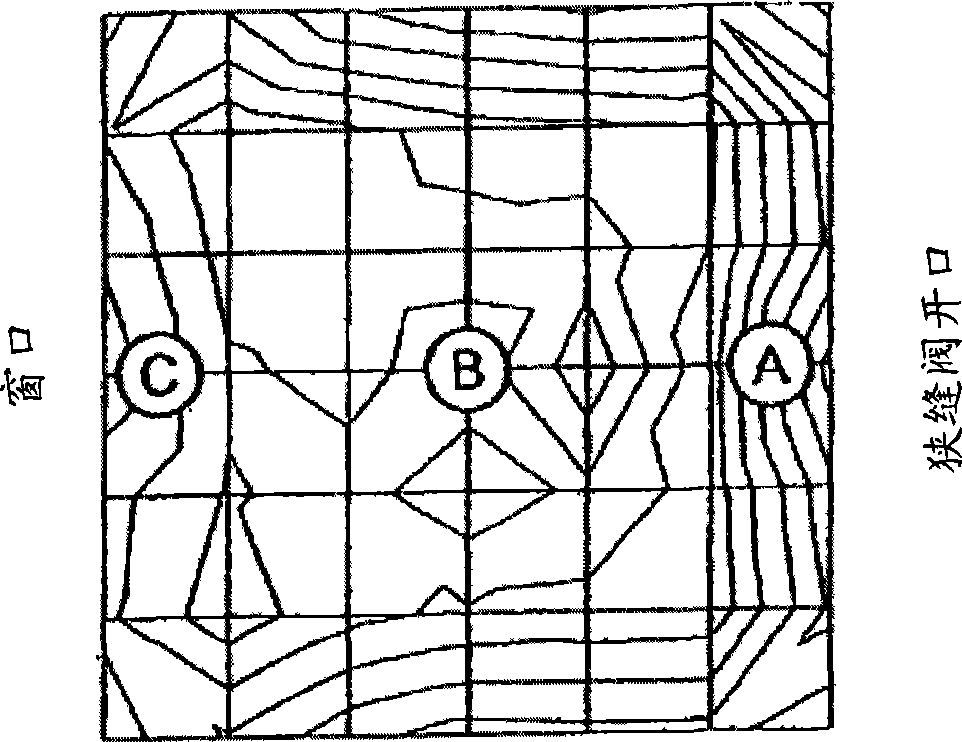

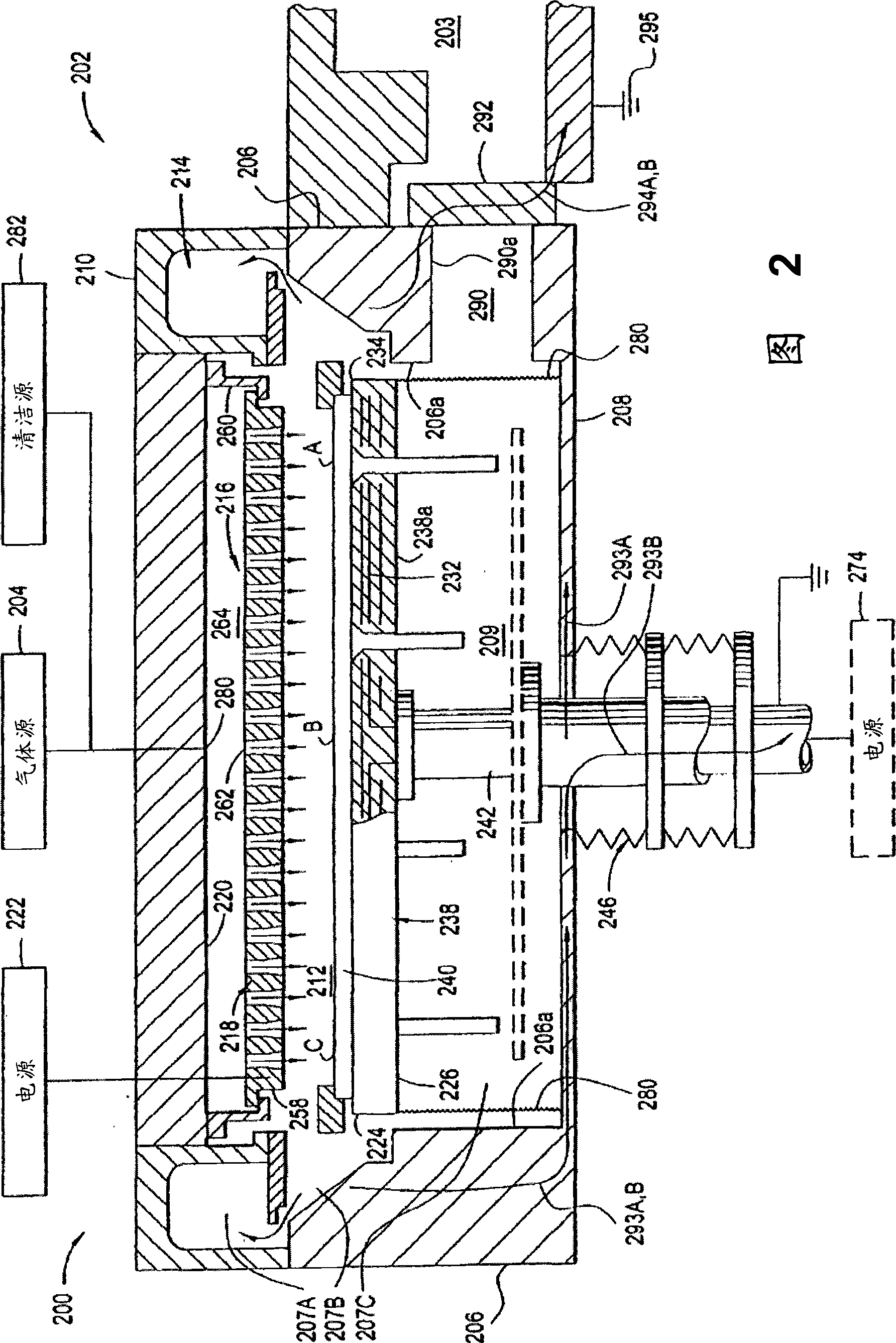

[0074] The present invention provides methods and equipment for improving the uniformity of films deposited on large-area substrates (especially films deposited in a PECVD system).

[0075] In one embodiment, the plasma processing chamber is constructed to be asymmetric with respect to the substrate during processing to compensate for the non-uniformity of plasma density in the chamber. In another embodiment, the plasma processing chamber is adapted to establish a neutral current shunt path, which can reduce the current, wherein the current flows through the characteristic structure in the chamber that generates the magnetic field. In another embodiment, the present invention provides a method of depositing a uniform film on a large area substrate in a plasma processing chamber. By establishing a neutral current shunt path, the chamber is constructed to be electrically symmetric during processing. The neutral current shunt path can substantially reduce the neutral current, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com