Method for radial flow chromatogram to remove protein in crude polysaccharide

A crude polysaccharide and protein technology, applied in the field of removing protein from crude polysaccharides, can solve the problems of large consumption of organic solvents, injury to operators, long operation cycle, etc., and achieve convenient follow-up processing, less environmental pollution, and short operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

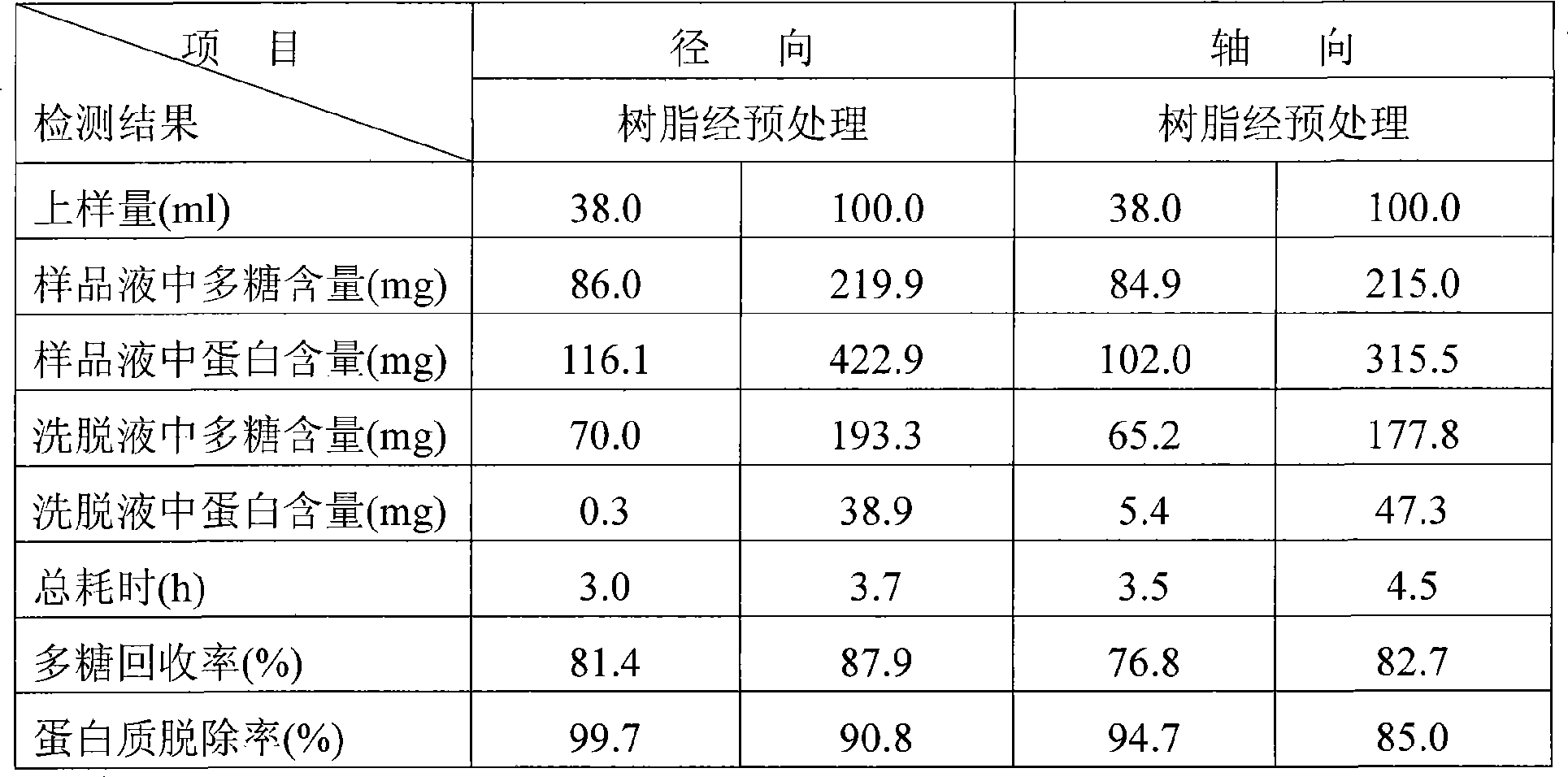

Image

Examples

Embodiment 1

[0026] Take the dried and crushed rapeseed meal, add water according to the ratio of rapeseed meal to water mass ratio of 1:20, extract at 95℃ for 2 hours, filter, concentrate the filtrate, precipitate the concentrate with alcohol, centrifuge, and take the precipitate Rapeseed crude polysaccharide is obtained by vacuum freeze-drying.

Embodiment 2

[0028] Take the dried and crushed rapeseed meal, add water according to the ratio of rapeseed meal to water mass ratio of 1:30, extract at 100°C for 4 hours, filter, concentrate the filtrate, precipitate the concentrate with alcohol, centrifuge, and take the precipitate Rapeseed crude polysaccharide is obtained by vacuum freeze-drying.

Embodiment 3

[0030] (1) Instruments and reagents:

[0031] Radial flow chromatography column (volume 250ml, Sepragen, USA), constant flow pump (BT00-300M, Baoding Lange Constant Flow Pump Co., Ltd.), beaker;

[0032] C104E, C107E weakly acidic cation exchange resins (provided by Deqing Bolaite (China) Co., Ltd.);

[0033] Rapeseed crude polysaccharide (obtained in Examples 1 and 2), Ganoderma lucidum polysaccharide (provided by Zhejiang Yisheng Fungus Development Co., Ltd.);

[0034] Hydrochloric acid solution, sulfuric acid solution, sodium hydroxide and potassium hydroxide are all analytically pure.

[0035] (2) The specific operation process is as follows:

[0036] 1. Resin pretreatment: Soak the C104E cation exchange resin provided by Deqing Bleachlight (China) Co., Ltd. in a 3% hydrochloric acid solution for 4 hours, wash with pure water to neutrality, and then place the resin in a 2% NaOH solution Soak for 2 hours, wash with pure water to neutral, and finally soak the resin in 3% hydroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap