Downwind aerogenerator gyrodamping and locking mechanism

A wind turbine and stop mechanism technology, applied to wind turbines, wind turbines, wind turbine components, etc. that are in line with the wind direction, can solve problems such as low efficiency, easy wear of parts, and easy swing of the wind turbine host, and achieve Improved work efficiency, simple operation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

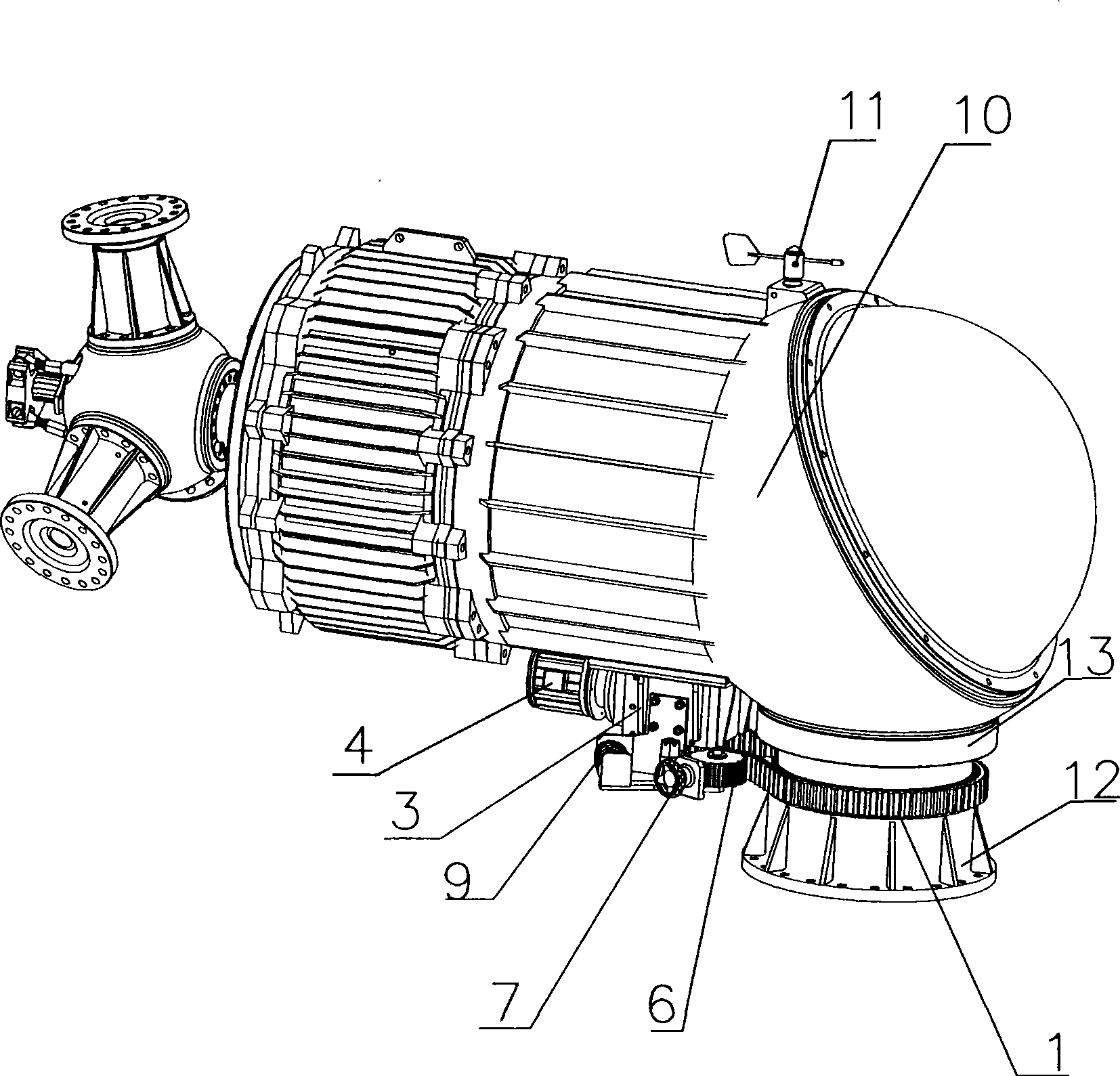

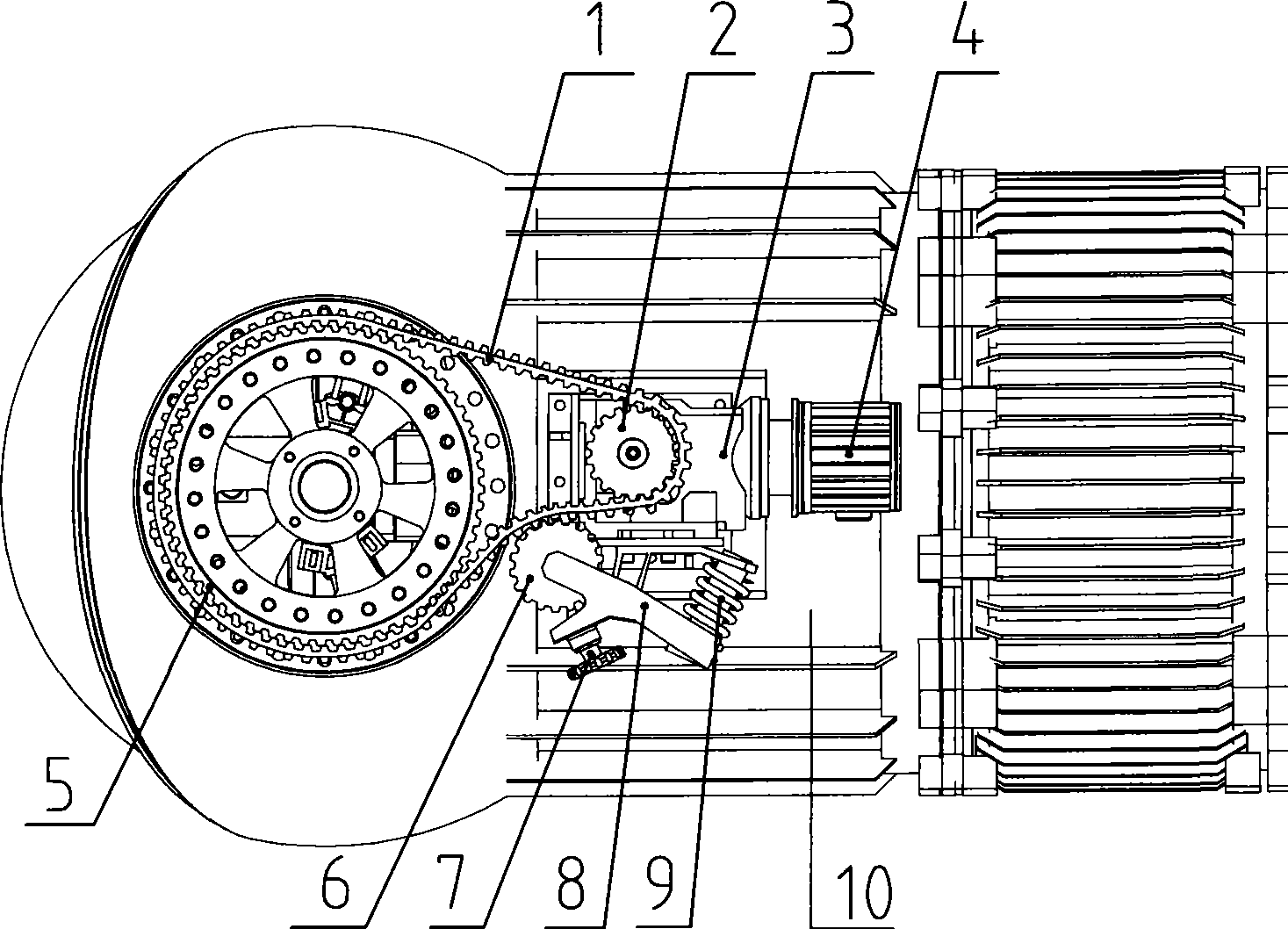

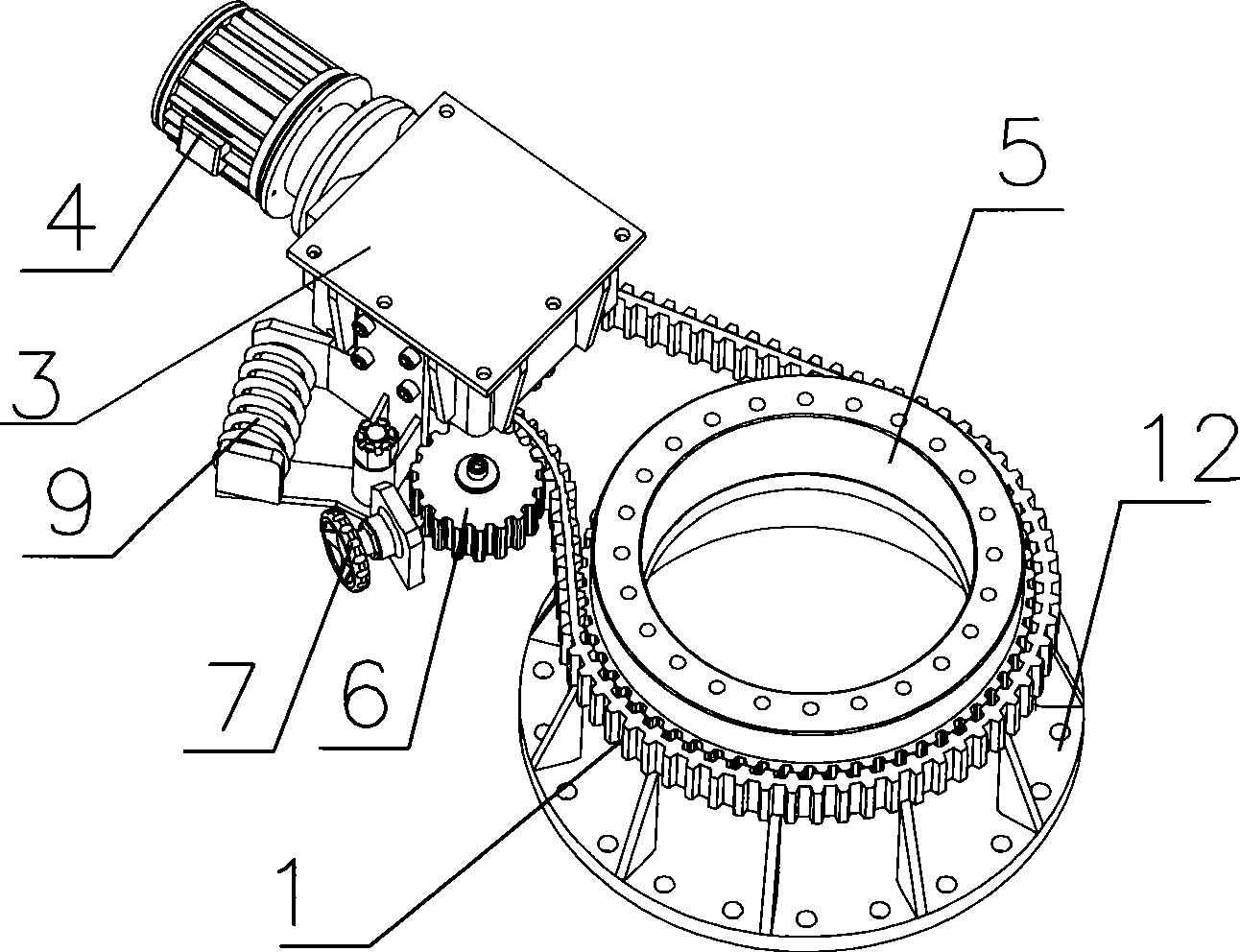

[0012] Such as figure 1 and figure 2 As shown, the rotation damping and stopping mechanism of the downwind wind turbine described in this embodiment includes an anemometer 11, a gear box 3, a motor 4, a small pulley 2, a large pulley 5, a timing belt 1 and a base flange 12. The wind direction indicator 11 is set on the top of the generator 10, the braking torque of the motor 4 increases the torque through the gearbox 3, the motor 4 is connected with the small pulley 2 through the gearbox 3, and the small pulley 2 and the large pulley 5 are synchronized through The belt 1 is connected, the tensioning wheel 6 is installed on the gearbox 3 through the bracket 8, the tensioning wheel 6 is provided with a spring 9 to increase the tensioning force, the large belt wheel 5 and the base flange 12 are fixed by bolts, and the base flange 12 is connected with generator 10 through slewing bearing 13. In the actual running process, the small pulley 2 revolves and rotates around the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com