Automatic strain measurement and monitoring system and method thereof

A technology of strain measurement and monitoring system, which is applied in the field of strain monitoring system and its management, can solve problems such as difficulty in installing and using the strain monitoring system, affecting the application of strain monitoring technology, and difficulty in realizing field monitoring objects, so as to improve data collection efficiency and Accuracy, easy installation and use, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be described in detail below.

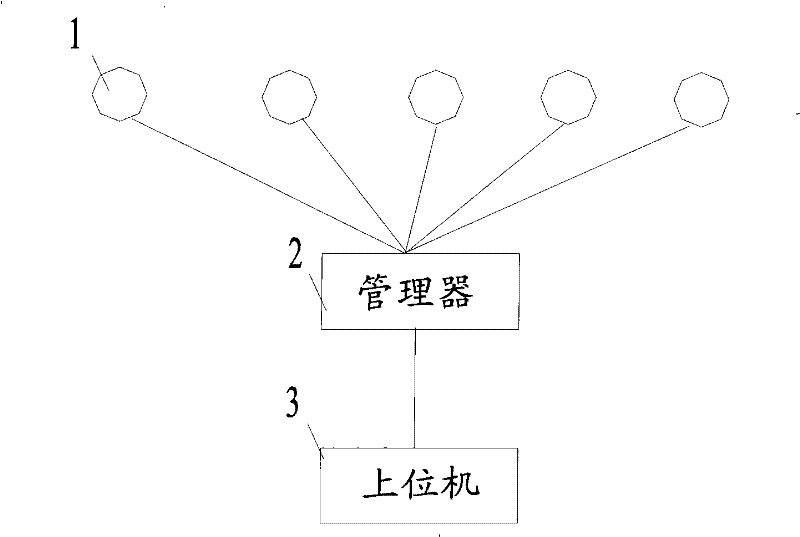

[0048] see figure 1 , the automatic strain measurement and monitoring system of the present embodiment includes a collector 1, a manager 2 and a host computer 3, wherein the collector 1 is used to collect the strain data of the monitored object and transmit it to the manager 2; the manager 2 is used for Receive the strain data transmitted by the collector 1 and transmit it to the host computer 3 to control and manage the collector 1; the host computer 3 is used to send control signals to the manager 2 and receive the strain data transmitted by the manager 2.

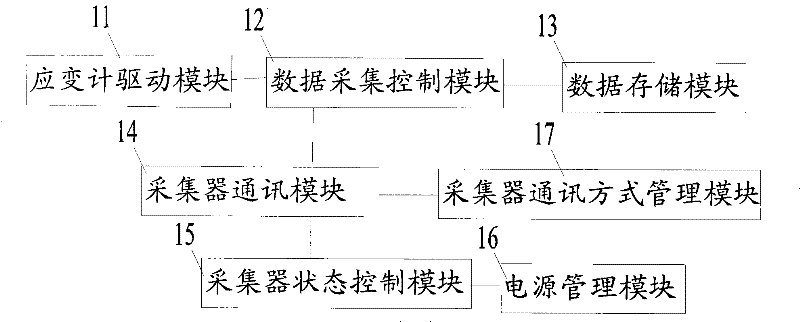

[0049] see figure 2 , the collector 1 includes a strain gauge driver module 11, a data acquisition control module 12, a data storage module 13, a collector communication module 14, a collector state control module 15, a power management module 16 and a communication mode management module 17, and the strain gauge driver module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com