Method for manufacturing a mixer-settler and a mixer-settler

A technology of mixing clarifier and wet method, applied in chemical instruments and methods, separation methods, solvent extraction, etc., to achieve the effect of favorable solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

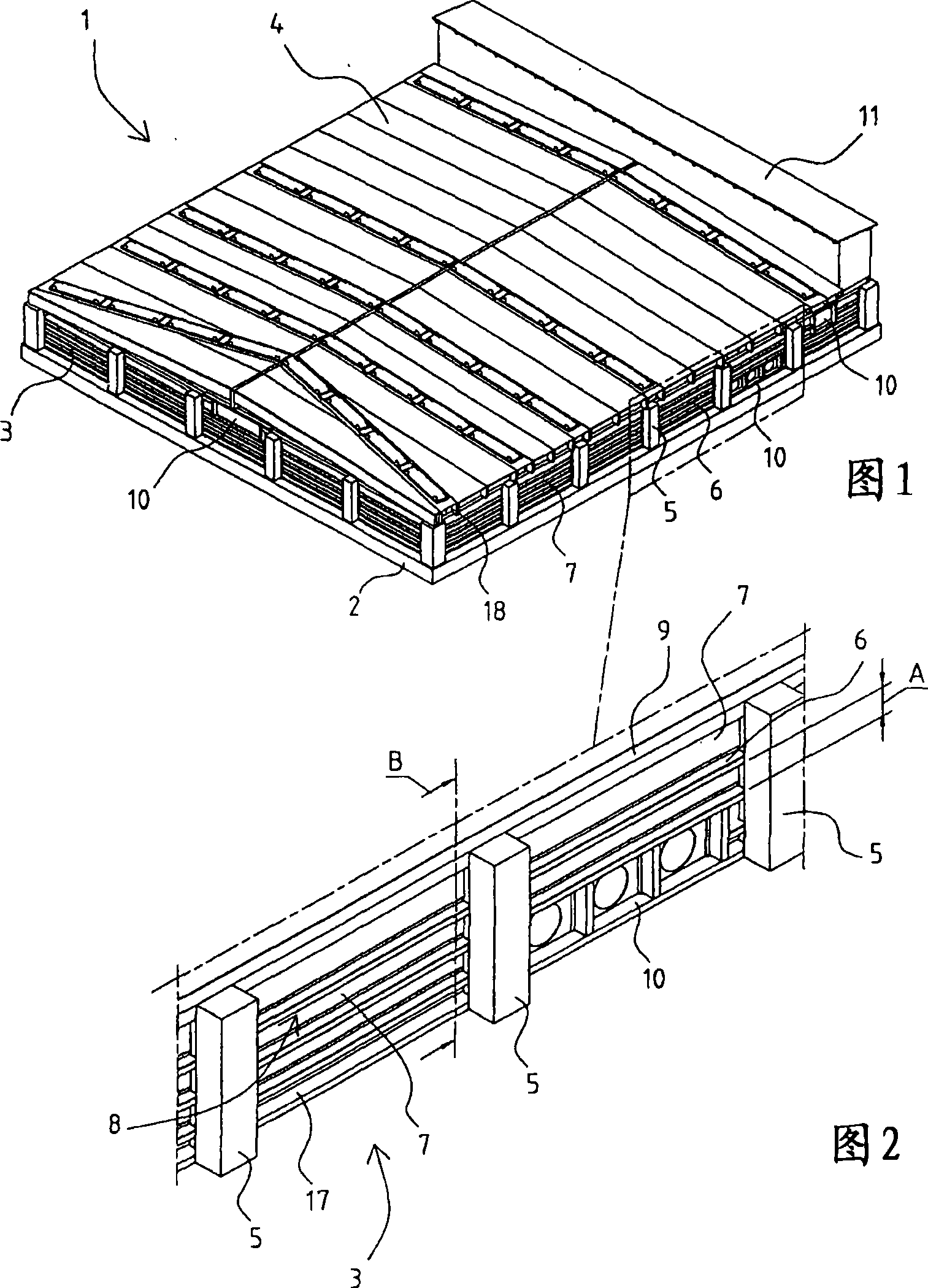

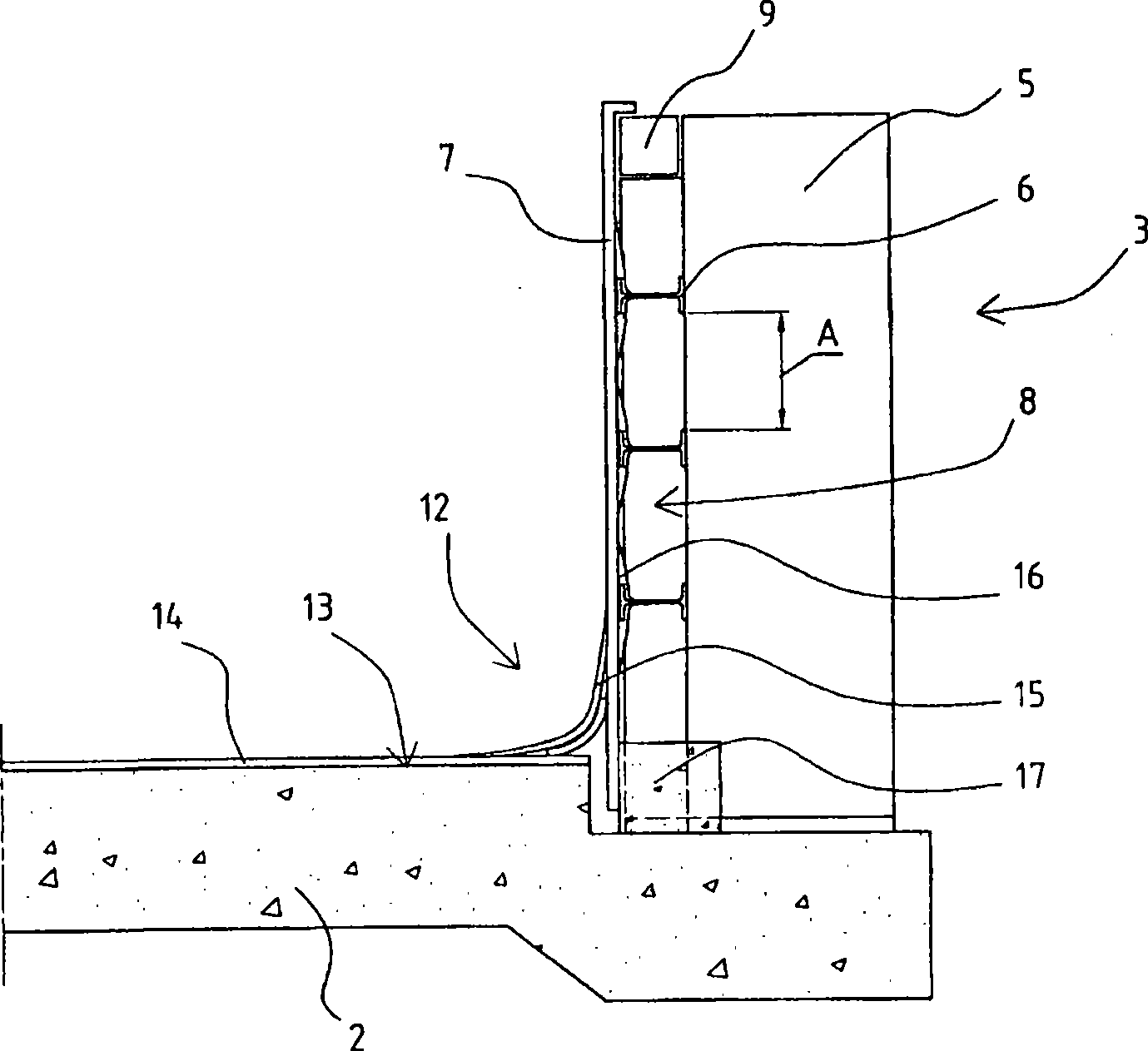

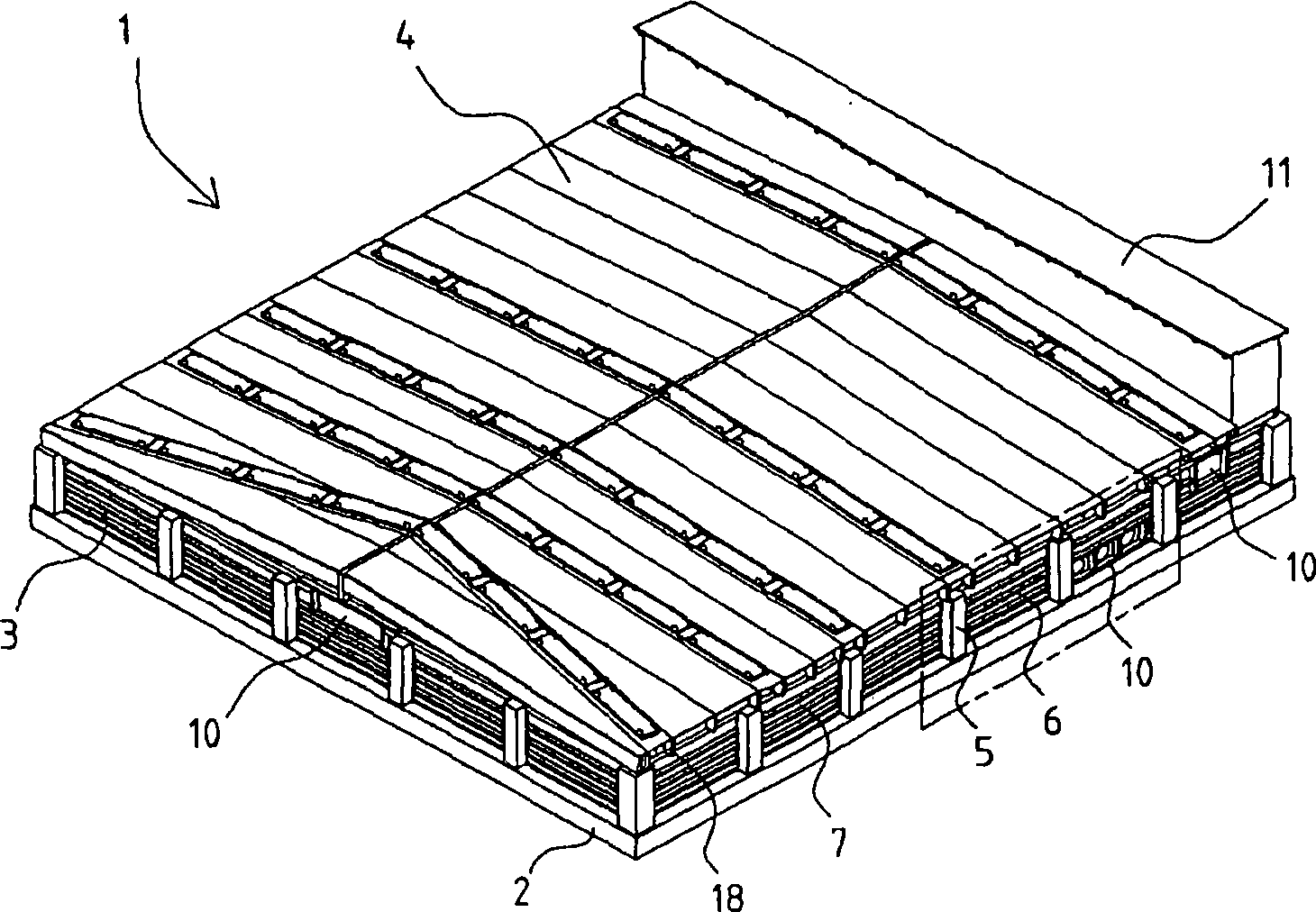

[0021] Figures 1, 2 and 3 show the structure of a mixer-settler according to the invention. image 3 is the cross-section of Figure 2 seen at point B. The solution treated in the mixer-settler 1 is flowed during the treatment in order to separate the desired metals from the solution. The concrete floor 2 of the mixer-settler is therefore cast to be inclined in the direction of solution flow so that the floor is higher at the end where the solution is fed into the mixer-settler. As regards the structure of the mixer-settler 1, the requirements imposed by the circulation of the extraction solution must be considered and the mixer-settler must be both chemically and structurally resistant. A mixer-settler 1 with an approximately rectangular sharp bottom is made of a vertical wall structure 3 in contact with the solution, a concrete cast sloping floor 2 and a cover structure 4 . The wall structure 3 is connected to the base plate 2 through vertical support columns 5 , and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com