Coil inserting method and coil inserting device

A coil insertion and coil installation technology, applied in the direction of prefabricated winding embedded in the motor, laying solid insulation, etc., can solve the problems of reduced motor efficiency and long coil circumference, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Implementation form 1

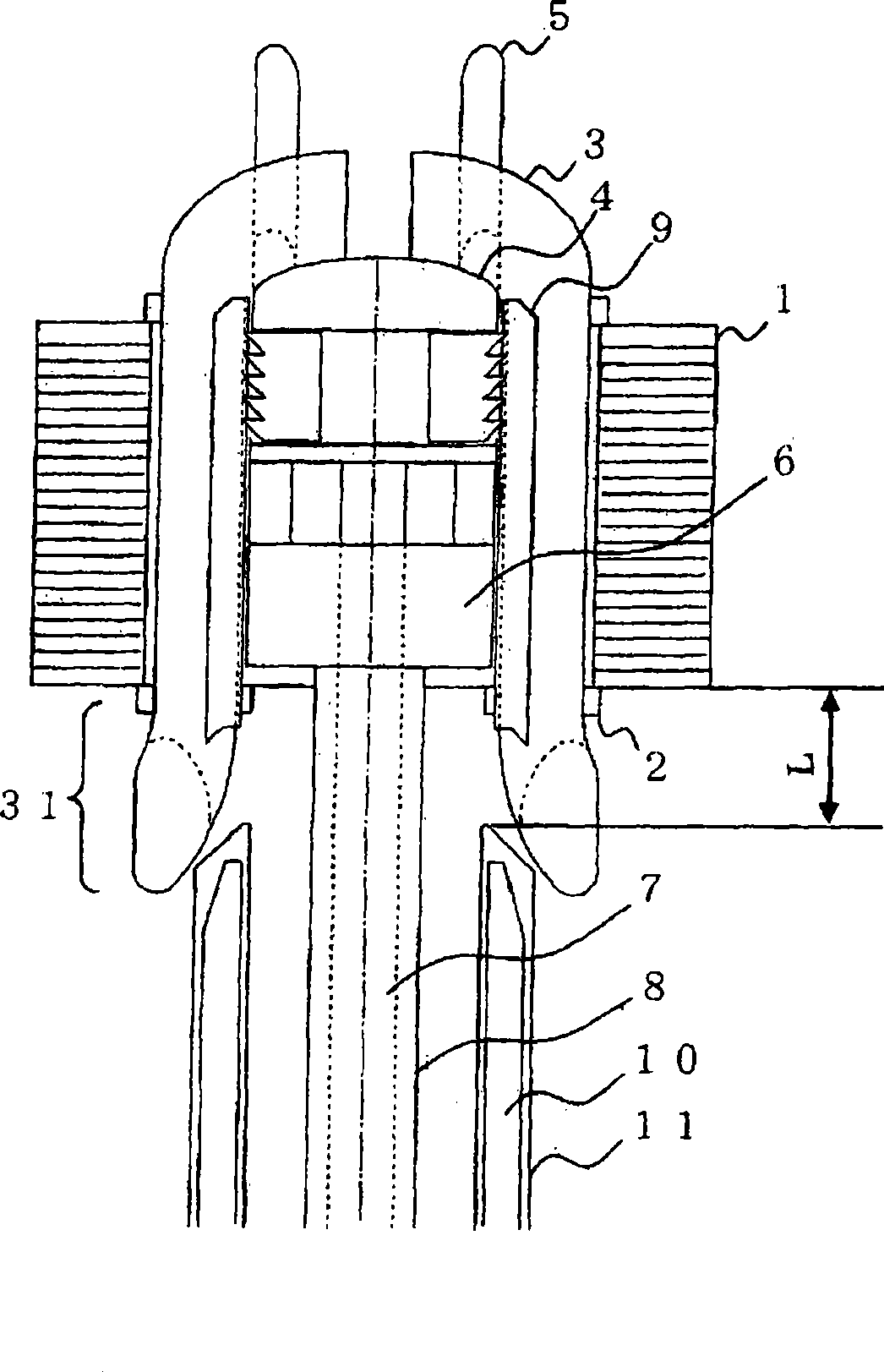

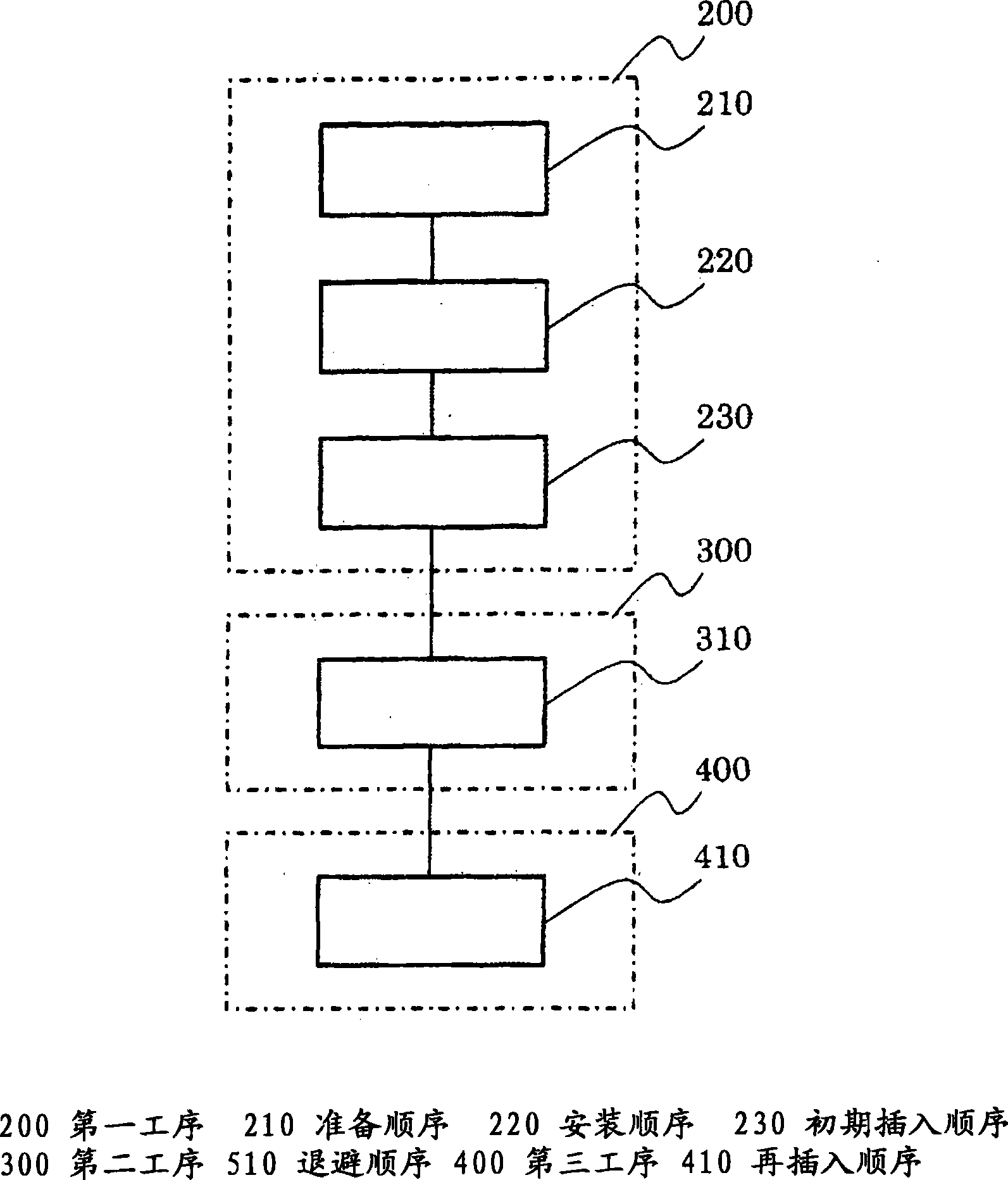

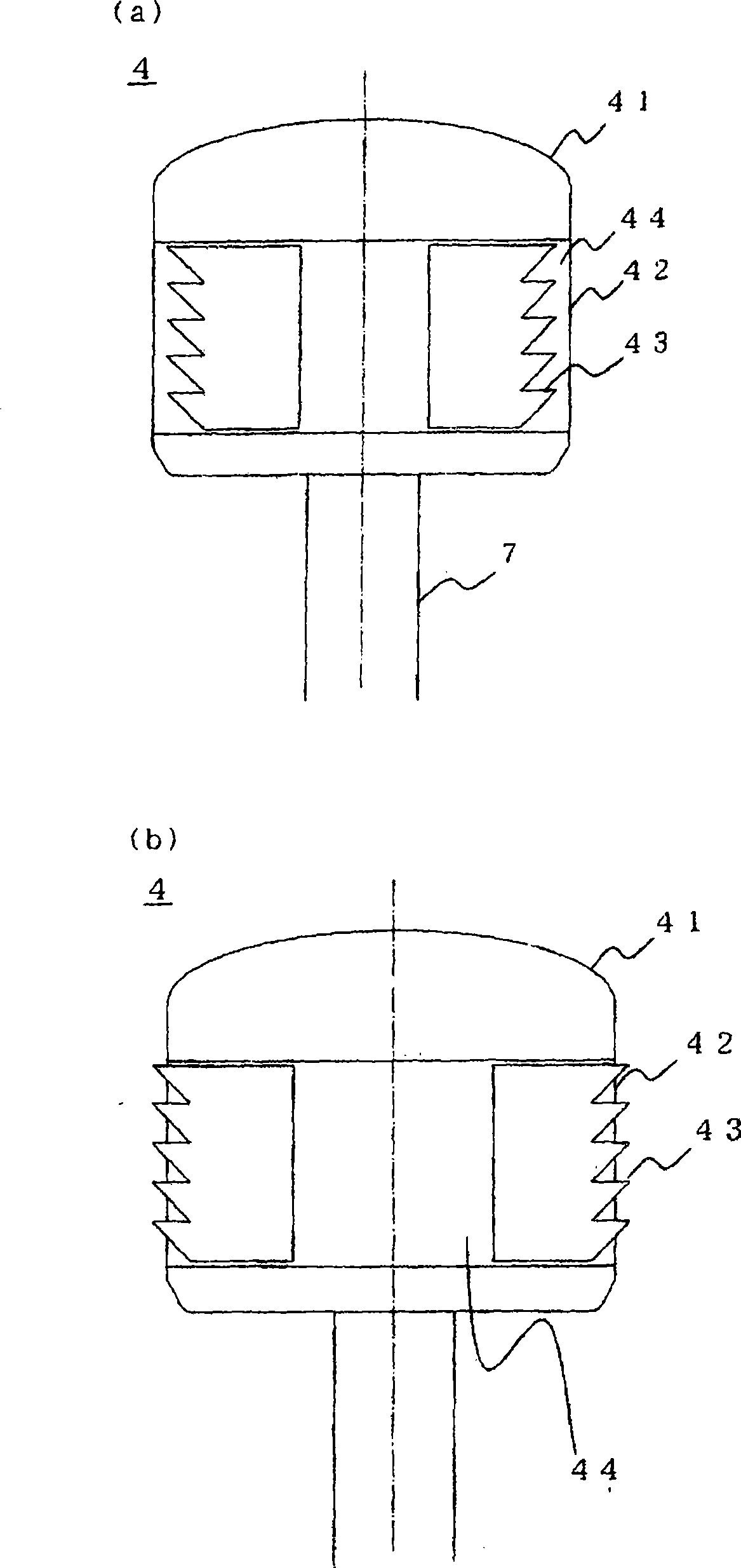

[0035] According to the invention of Embodiment 1, using the coil insertion device equipped with the blade, the separator, the slot wedge pusher, and the slot wedge guide, the wound coil and each slot insertion unit of the coil are bundled and insulated. When the slot wedge is inserted into the slot of the iron core constituting the motor, the coil insertion end of the iron core is separated from the front end of the slot wedge guide by a predetermined distance during the coil insertion process, and then the coil insertion process is continued.

[0036] figure 1 It is a diagram showing a method of inserting a coil into a core slot using the coil inserting device according to Embodiment 1 of the present invention, and shows a state when the coil insertion is completed. Here, the slot refers to a space formed by a stator core for winding a coil and forming a magnetic pole, and a plurality of teeth that are protruding protrusions protruding in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com