Vibration absorption bonding apparatus

A lap joint device, vibration isolation technology, applied in the direction of circuit layout on the support structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

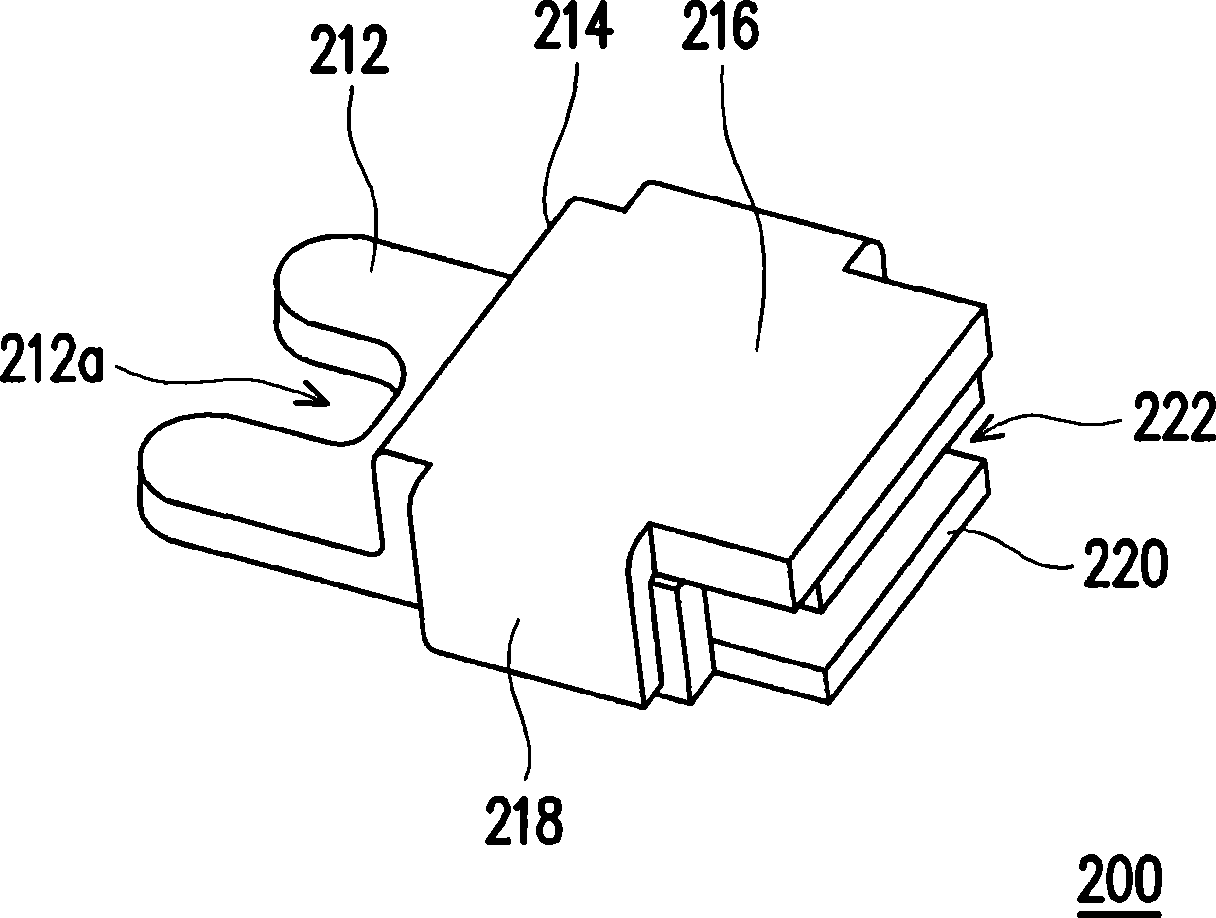

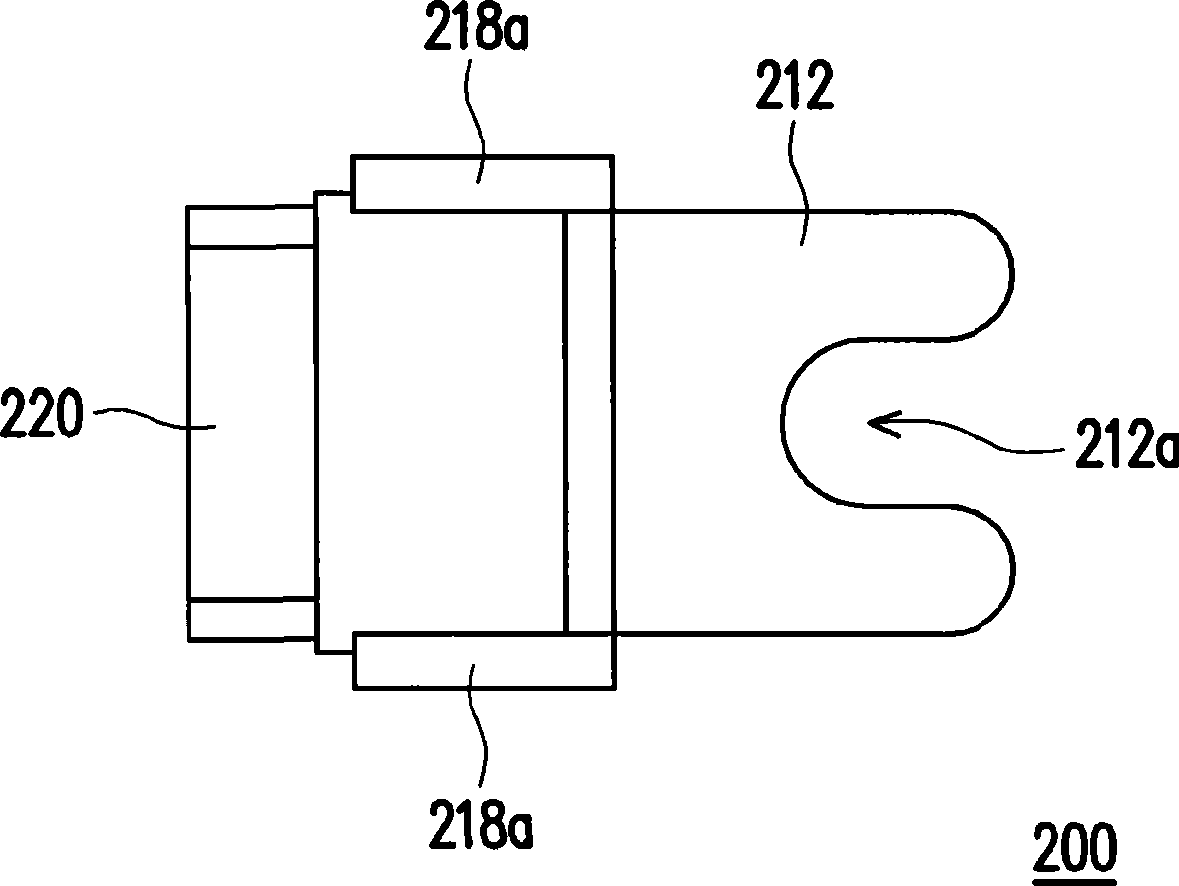

[0018] Figure 2A and Figure 2B It is a top view and a bottom view schematic diagram of a vibration isolation lap joint device according to an embodiment of the present invention, and image 3 It is a schematic diagram of the partial structure of the first structure and the second structure of the vibration isolation lap joint device in FIG. 2 . The vibration isolation lapping device 200 includes a lapping sleeve 210 and a vibration isolator 220 for fixing the first structure 230 on the second structure 240 . The lap sleeve 210 has a lower plate portion 212 , a vertical wall 214 , an upper plate portion 216 and two side plate portions 218 . The lower plate portion 212 has a notch 212 a, and the vertical wall 214 is connected between the lower plate portion 212 and the upper plate portion 216 . The two side plate portions 218 are connected to the upper plate portion 216 and form a receiving groove for receiving the vibration isolator 220 .

[0019] Please refer to image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com