Thermoelectric generator with micro-electrostatic energy converter

A technology for thermoelectric generators and electrostatics, applied in the direction of electrochemical generators, thermoelectric device junction lead materials, thermoelectric devices that only use the Peltier or Seebeck effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

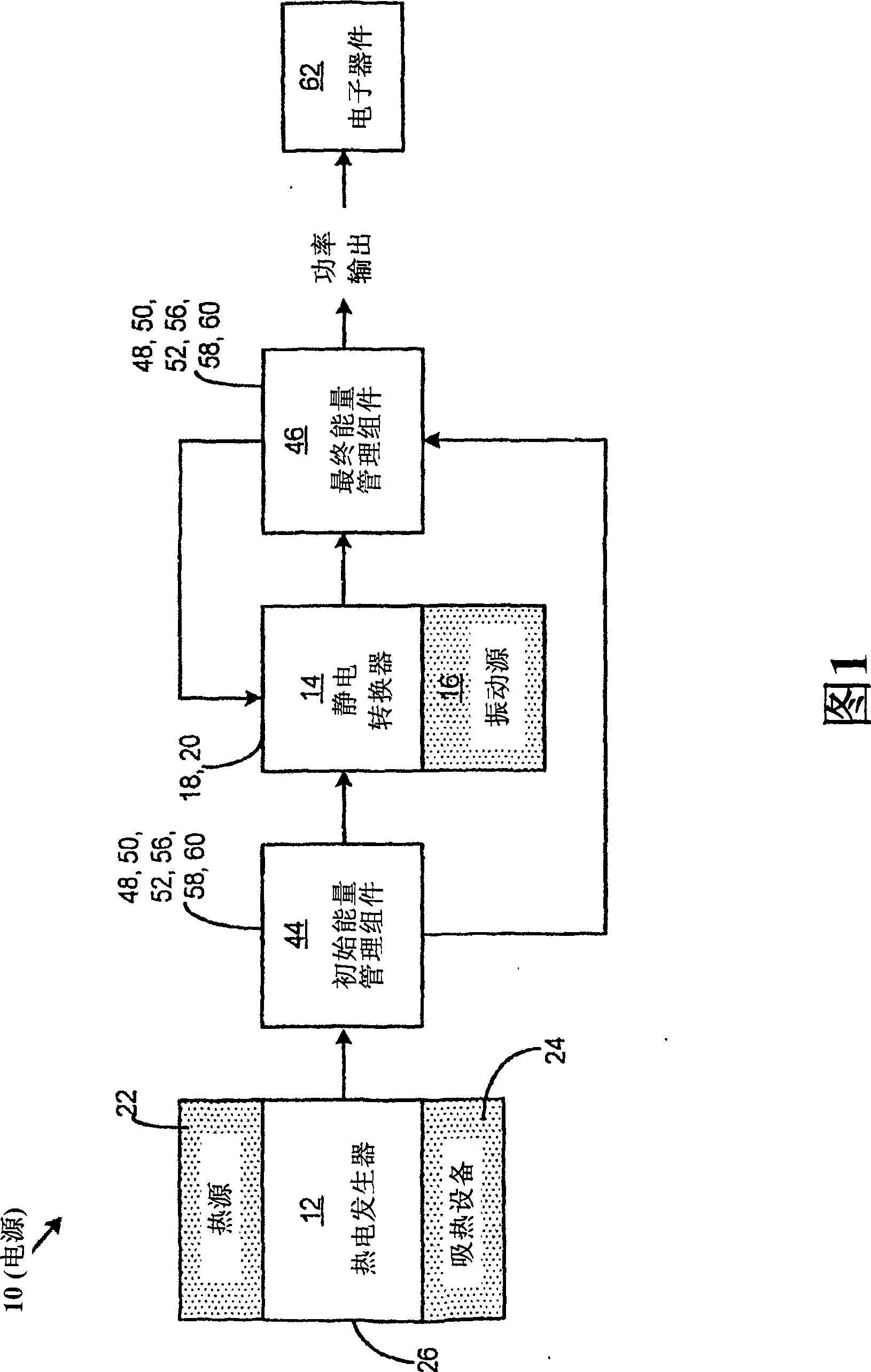

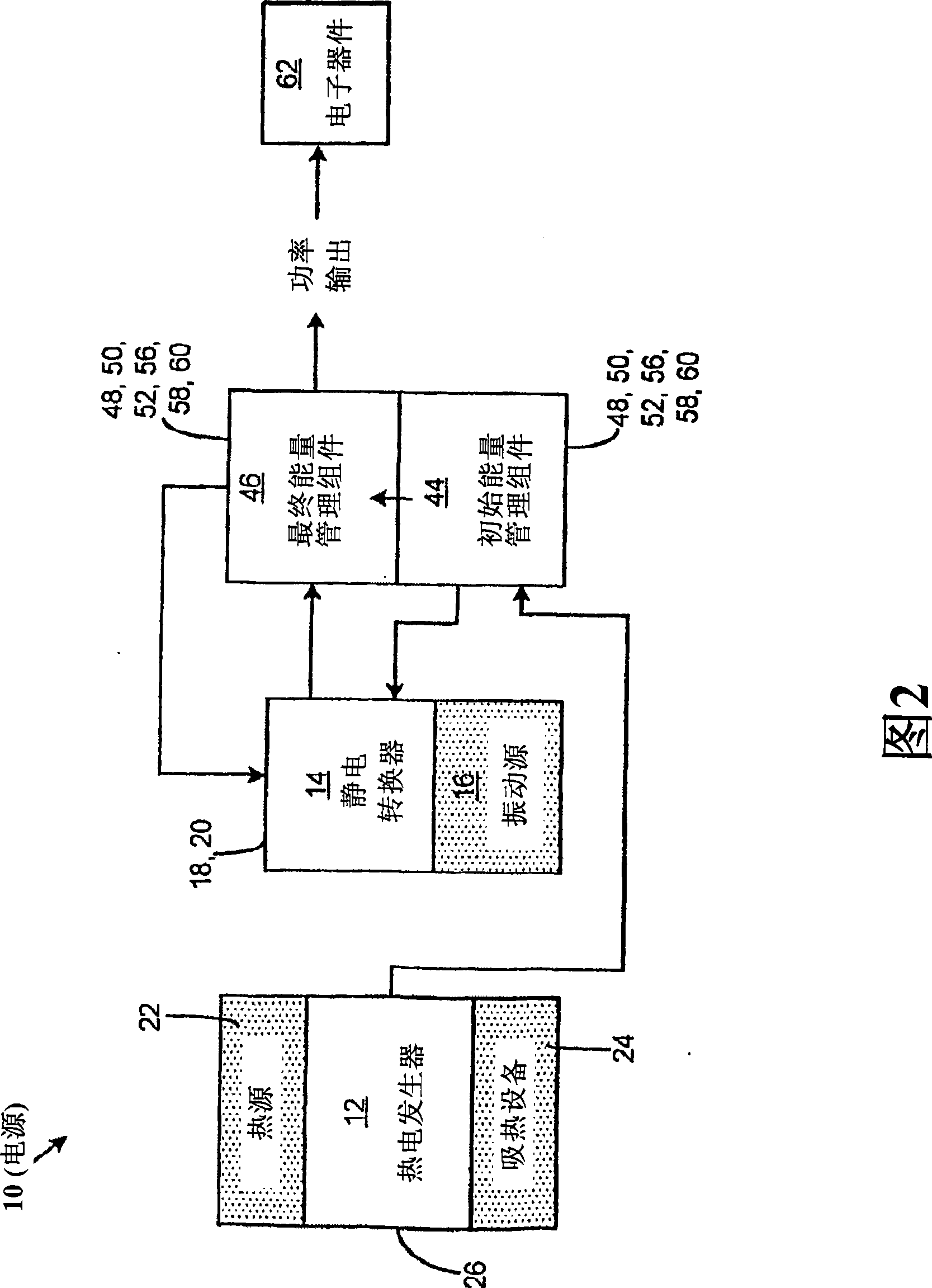

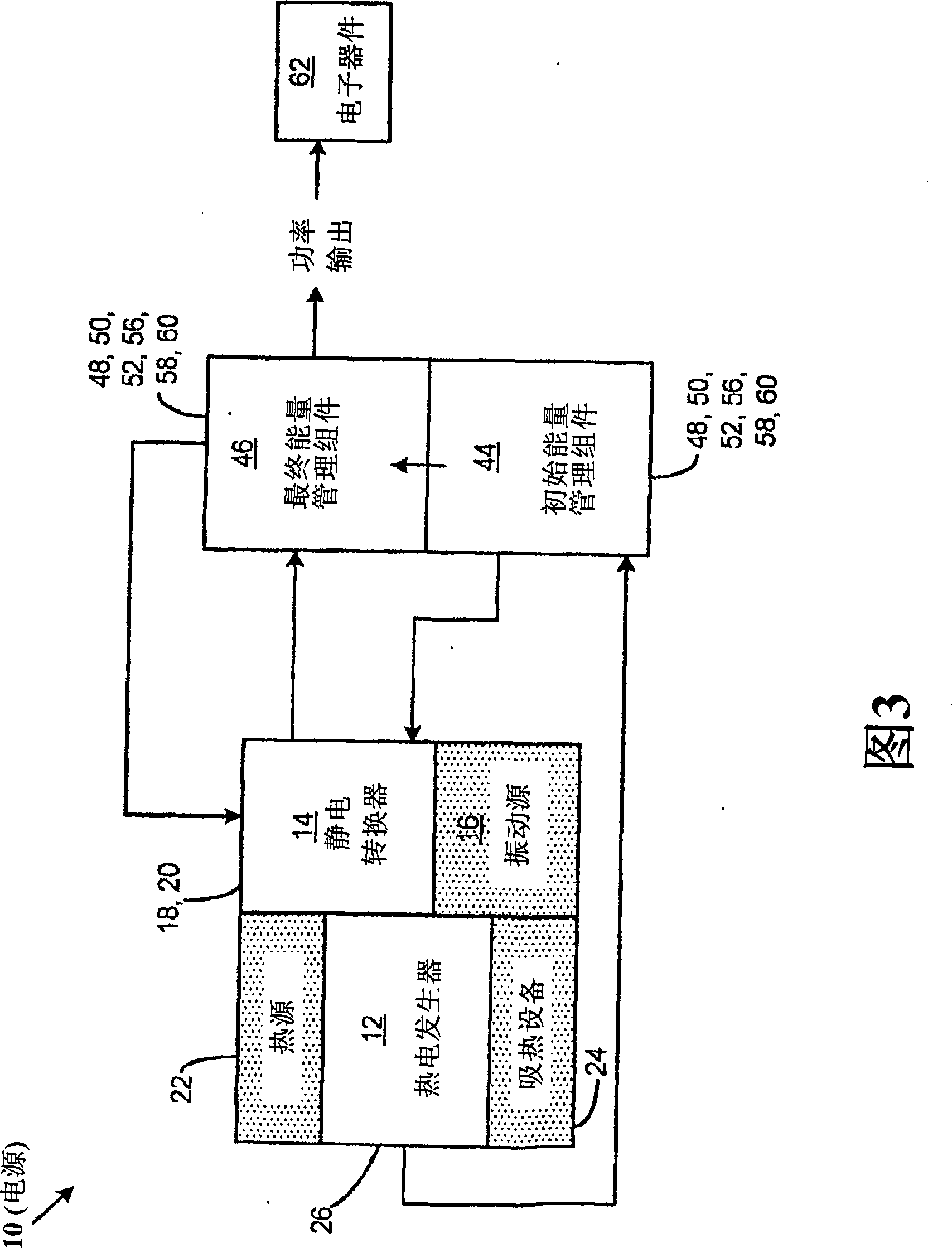

[0025] Reference is now made to the drawings, which are used to illustrate preferred embodiments of the invention and not to modify the invention. As shown in FIG. 1 , it is a schematic diagram of a power source 10 specifically for converting mechanical energy into electrical energy. Advantageously, the power supply 10 of the present invention is used to generate a relatively stable and continuous electrical power supply sufficient for the power required by microelectronic devices and sensor systems.

[0026] In the broadest sense, the power supply 10 includes a thermoelectric generator 12 , an initial energy management component 44 , an electrostatic converter 14 and a final energy management component 46 . The thermoelectric generator 12 is used to generate electrical activation energy of a sufficiently high voltage in response to a temperature gradient acting across the thermoelectric generator 12; an initial energy management assembly 44 is connected to the thermoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com