Pipe bender with mandrel driving mechanism

A driving mechanism and pipe bending machine technology, which is applied in the field of pipe bending machines, can solve problems such as low processing efficiency, affecting the quality of pipe fittings, vibration, etc., and achieve the effects of improving pipe bending efficiency, reducing length, and improving pipe bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

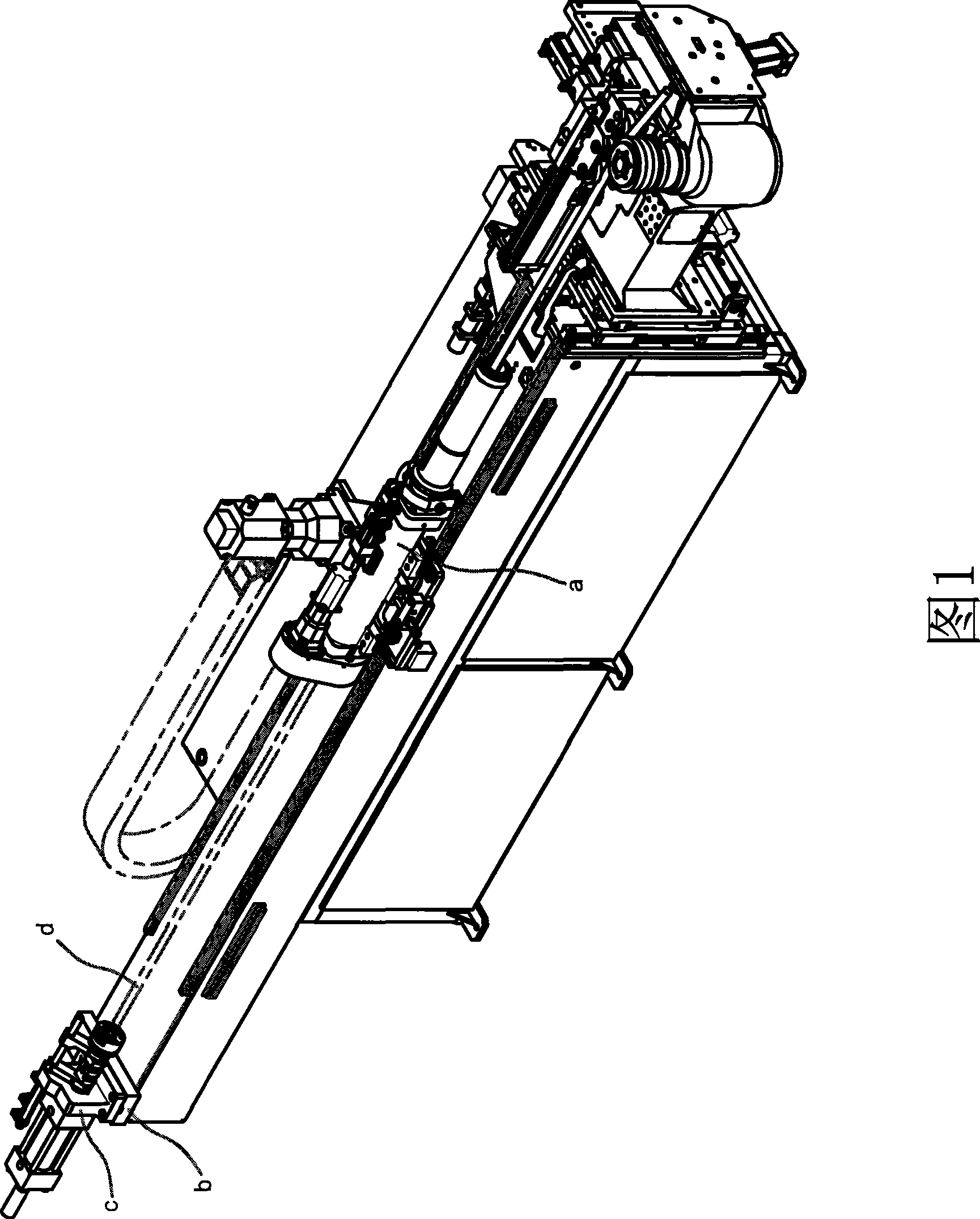

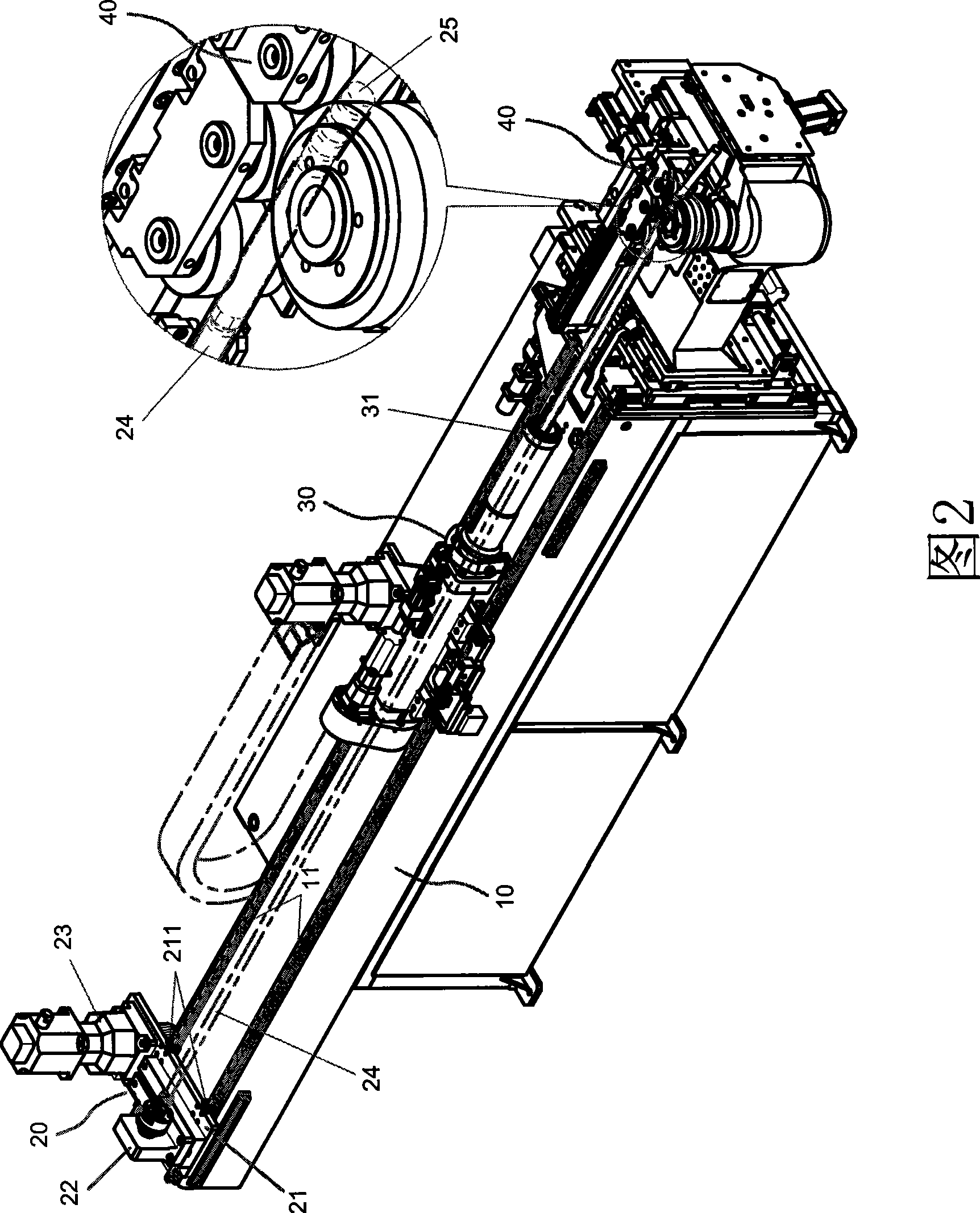

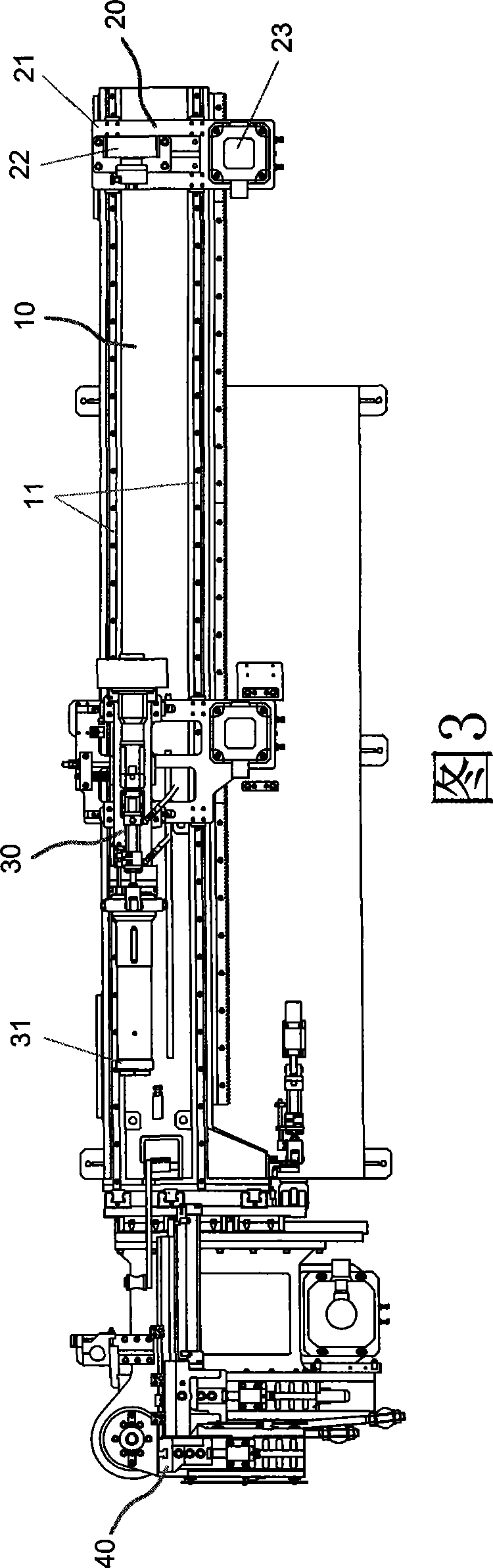

[0023] Below with regard to the structural composition and the effect that can produce of the pipe bender that has through core drive mechanism of the present invention, cooperate accompanying drawing to describe in detail as follows with preferred embodiment:

[0024] Please refer to Fig. 2 and Fig. 4, the present invention has a pipe bender with a core-through drive mechanism, including:

[0025] The machine platform 10, the drive device 20 for opening the core, the pipe pushing device 30 and the pipe bending device 40.

[0026] Machine base 10, machine base 10 is provided with numerical control device (not shown in the figure), this kind numerical control device belongs to general CNC numerical control system, is a known technology, no longer described here. The machine table 10 is provided with a set of rails 11 for setting the subsequent drive device 20 for opening the core and the device for pushing the pipe fittings 30 .

[0027] Passing core driving device 20, connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com