Suspension type active vibrating block-resistant type material bin

A material silo and suspension type technology is applied in the field of suspended live vibration and anti-blocking material silo, which can solve the problems of poor feeding, easy blockage of the outlet of the hopper, and easy damage to the base material silo body by the rapping motor. , to achieve the effect of increasing the hitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

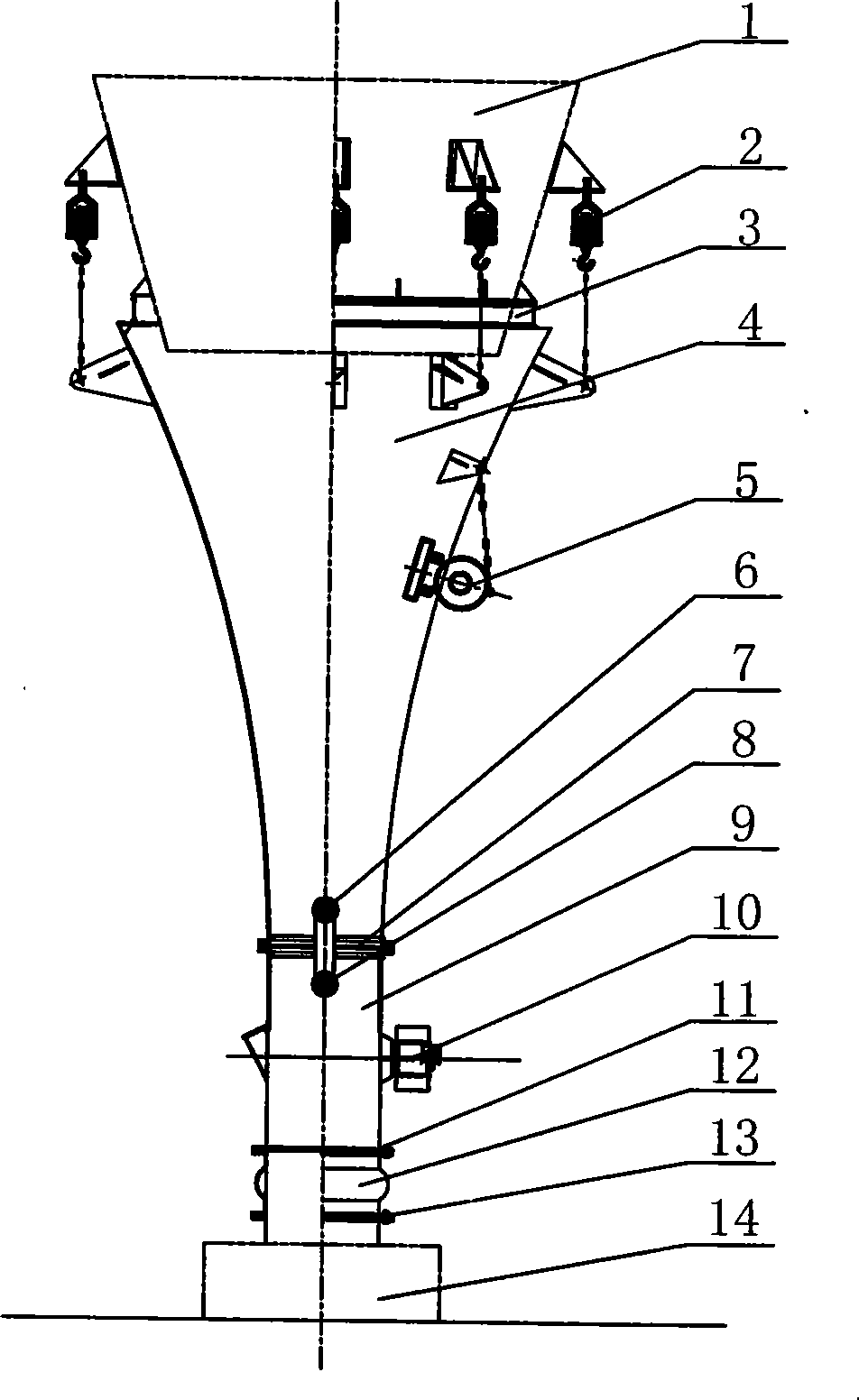

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] see Attachment

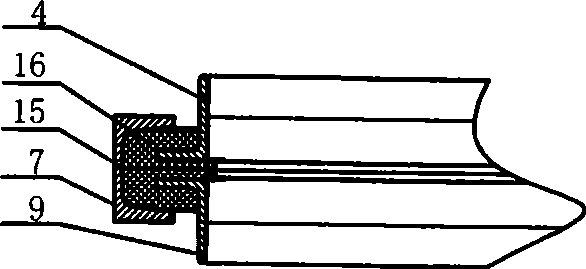

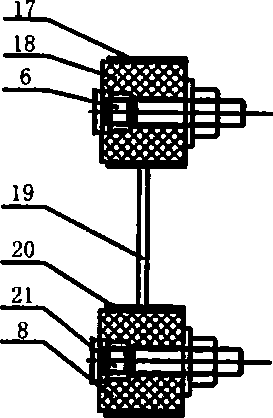

[0011] Suspended living vibration anti-blocking type material bin, the material bin is composed of connecting bin 4 and outlet bin 9, the outlet bin 9 is set under the connecting bin 4, connecting bin 4 and fixed bin 1 are connected by suspension elastic, and the general connection can be divided There are two connection methods, one is the suspension connection through multiple sets of spring hook assemblies 2, and the other is the floating connection of the horizontal compression spring. A flexible seal 3 is arranged between the joint of the connecting warehouse 4 and the fixed warehouse 1, and the sealing member adopts nitrile rubber sheet and stainless steel mesh cloth as the sealing material to ensure its sealing effect and flexible connection.

[0012] A flexible seal assembly 7 is provided at the connection between the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com