Mounting structure for engine accessory belt pulley

A technology of installation structure and pulley, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of increasing the external dimensions of engine accessories, affecting the external dimensions of the engine, and increasing manufacturing costs, so as to improve working conditions, prolong life, and improve The effect of bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

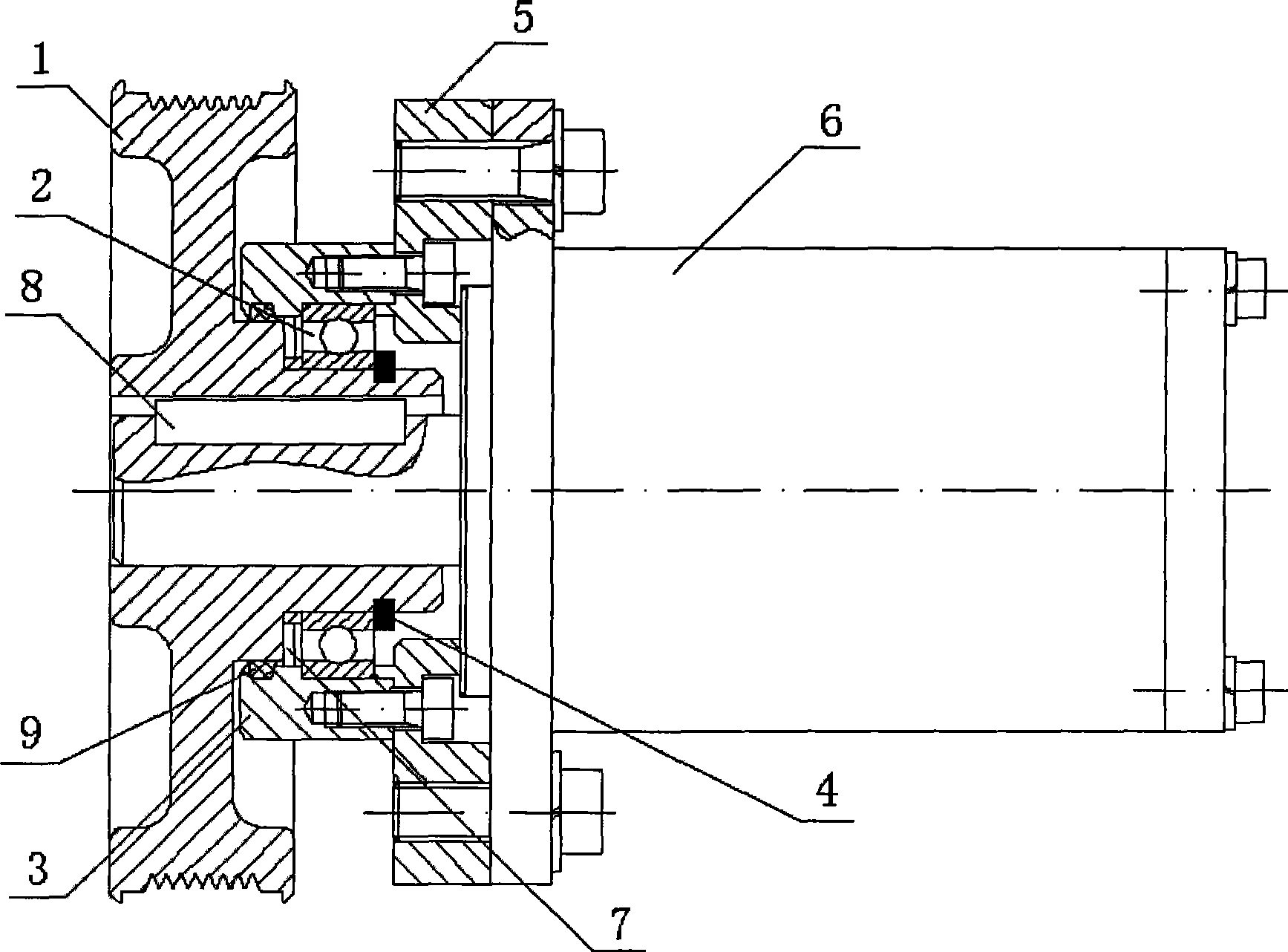

[0016] figure 1 Shown is a schematic diagram of an installation structure of an engine accessory pulley.

[0017] Depend on figure 1 It can be seen that the installation structure of the engine accessory pulley includes the engine accessory 6 and the accessory pulley 1, one end of the accessory pulley 1 is installed in the bracket 3 with the bearing 2, and the bearing 2 is coaxially installed inside the bracket 3 and passed through the retaining ring 4 is fixed, one end face of the bearing end cover 5 is connected with the bracket 3, and the other end face is connected with the shoulder of the engine accessory 6, the bearing end cover 5, the bracket 3 and the engine accessory 6 are all fixed by bolts, and the engine accessory 6 One end is installed inside the accessory pulley 1 through the flat key 8, and the adjusting gasket 7 is installed on the accessory pulley 1, first install the adjusting gasket 7 on the accessory pulley 1, and then install the accessory pulley 1 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com