Intermittent drive and connecting bar combined mechanism and use thereof

A combined mechanism and connecting rod technology, which is applied in transmission devices, mechanical equipment, educational appliances, etc., can solve problems such as lack of functions and complex structures, and achieve the effects of accurate coordination of actions, shortening of operating time, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

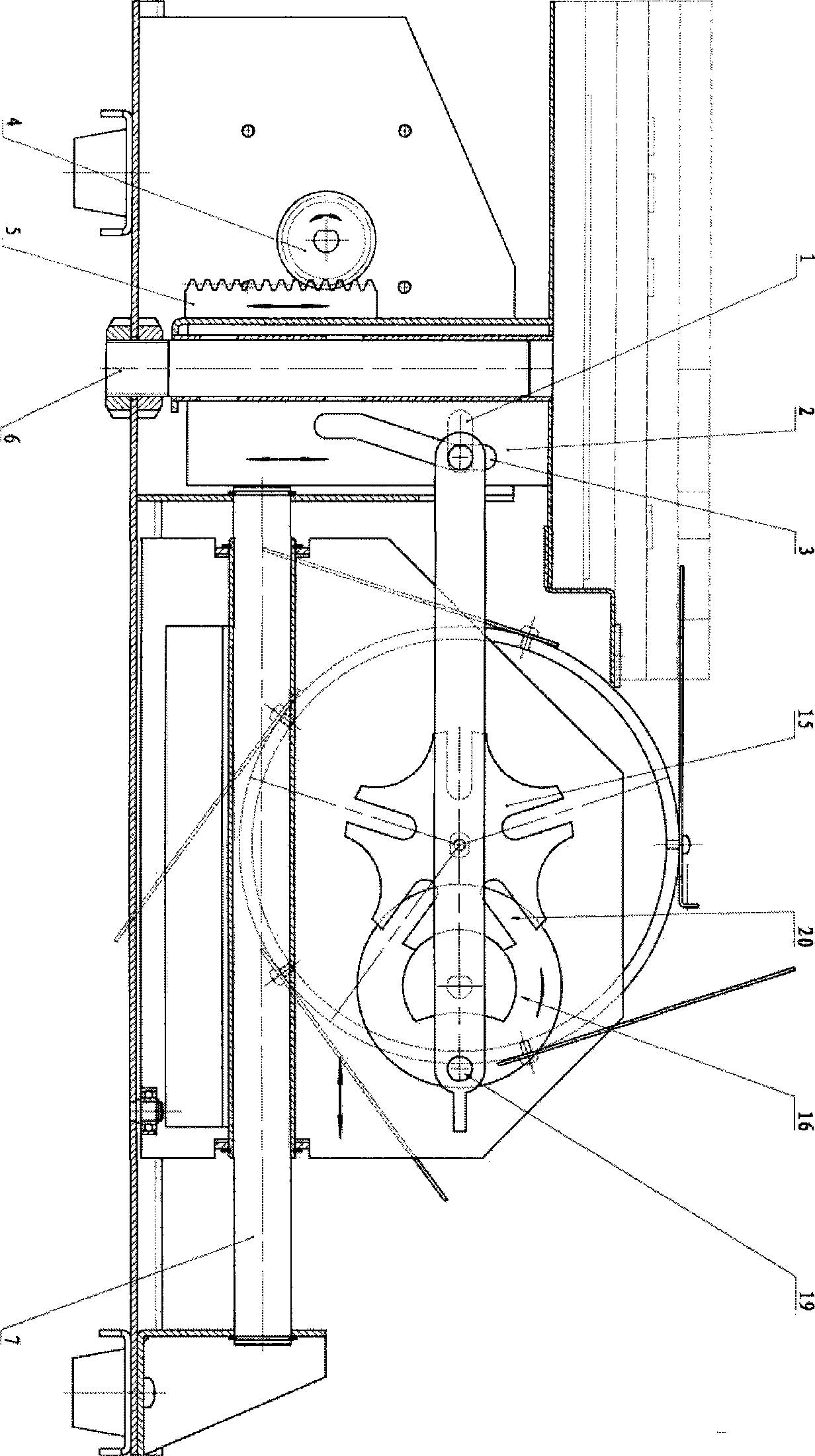

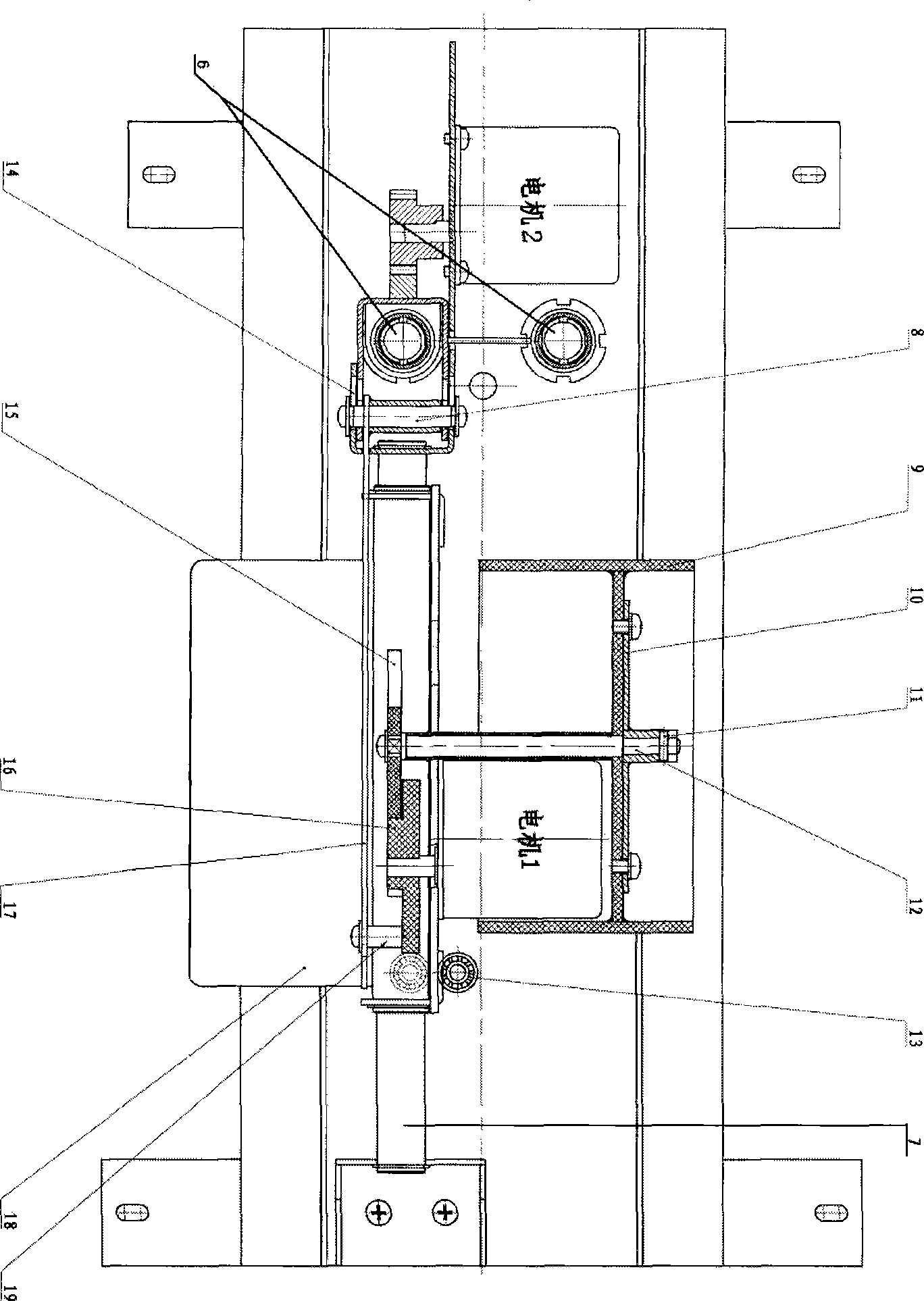

[0011] figure 1 in and figure 2 The combined mechanism of intermittent transmission and connecting rod shown in has: a movable frame (18) and a breathing part (2). Among them, the movable frame (18) is equipped with a motor 1, a rotating cylinder (9), an adjustment plate (10), a rotary shaft (12), a pin wheel (16), a sheave (15), and a connecting rod (17). The bearing (13) and the guide rod (7) define the movement route of the frame; the breathing part (2) is driven by the motor 2, the gear (4) and the rack (5), and moves along the guide post (6).

[0012] Rotary cylinder (9) is fixed on the adjusting disc (10), and adjusting disc (10) is fixed on the rotating shaft (12) through cylindrical pin (11); One end of rotating shaft (12) is fixed with a sheave (15), and the groove Wheel (15) fits with the pin wheel (16) fixed on the motor 1; the round pin (19) on the pin wheel (16) is sleeved on the connecting rod (17); one end of the connecting rod (17) passes through the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com