Gear missing prevention device for rotary tillage rake

A technology of rotary tillage harrow and reverse gear, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., and can solve the problems of increasing the width of the rotary tillage harrow, easily damaged tooth angles, and large noise , to achieve the effect of prolonging the working life, improving safety performance and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

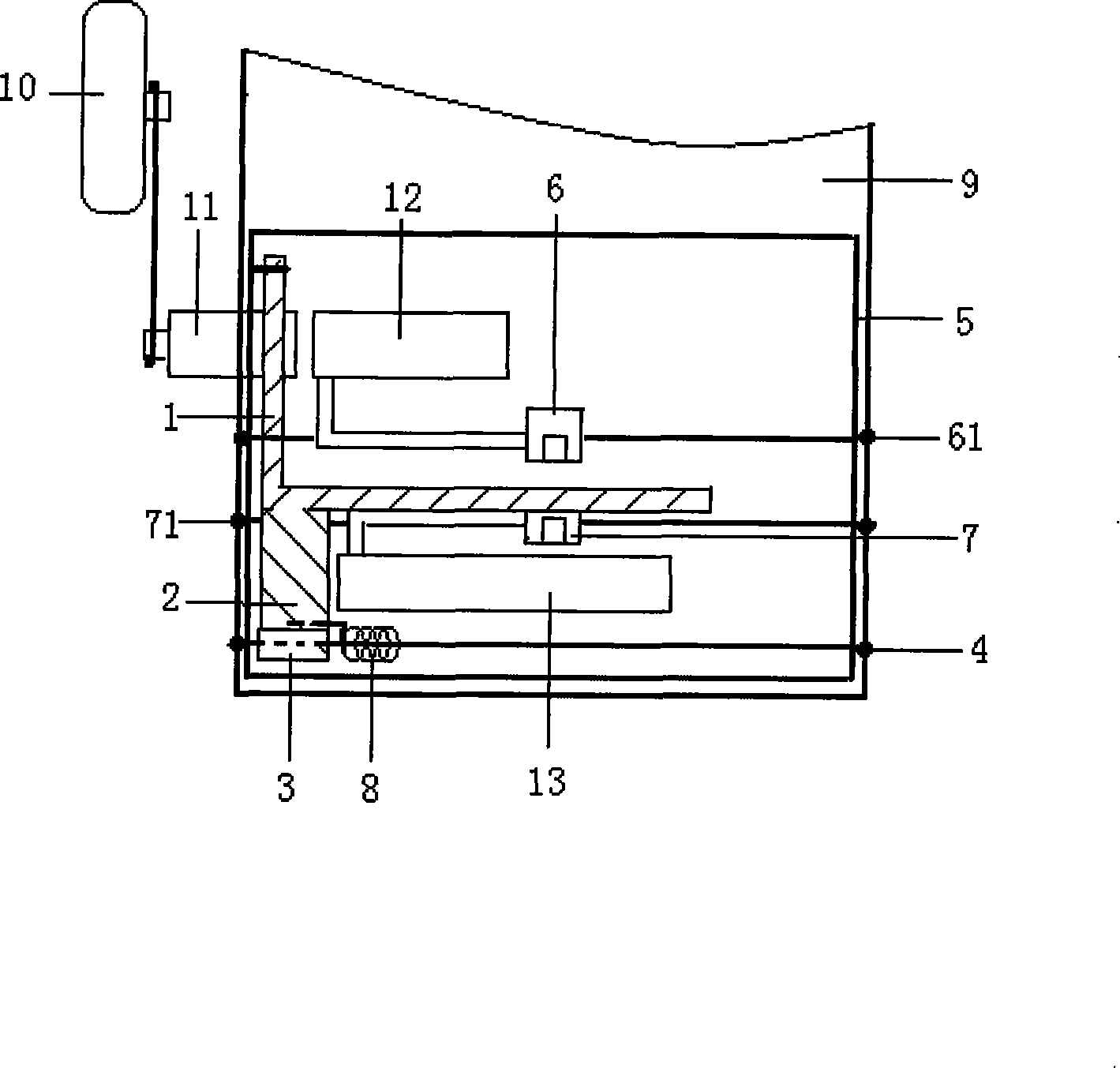

[0014] As shown in the figure, the present invention is mainly composed of a limit pressure rod 1, a limit plate 2, a rotating sleeve 3, and a fixed shaft 4, and is placed in a fixed box 5. During installation, as long as the working gear shift fork shaft 61 and the reverse gear shift fork shaft 71 are taken off, the fixed box can be put into the gearbox, and then the shift fork shaft is installed to the original position through the left and right walls of the fixed box. The limit pressure rod is arranged between the shift fork 6 of the working gear of the gearbox and the shift fork 7 of the reverse gear. In the figure, the limit pressure bar is in the shape of a right-angle turn, wherein the parallel right-angle bar 11 is parallel to the left and right frames of the fixed box, and is flexibly connected with the left frame, and the right-angle bar 12 perpendicular to the parallel right-angle bar is along the reverse gear The shift fork 7 upper openings are arranged; one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com