Method for forming a tilting zone on a transverse element for a push belt for a continuously variable transmission

A technology of continuously variable transmission and transverse elements, applied in the direction of household elements, belts, V-shaped belts, etc., can solve the problems of unreached pressure level, danger, deviation of the shape of the inclined area, etc., and achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

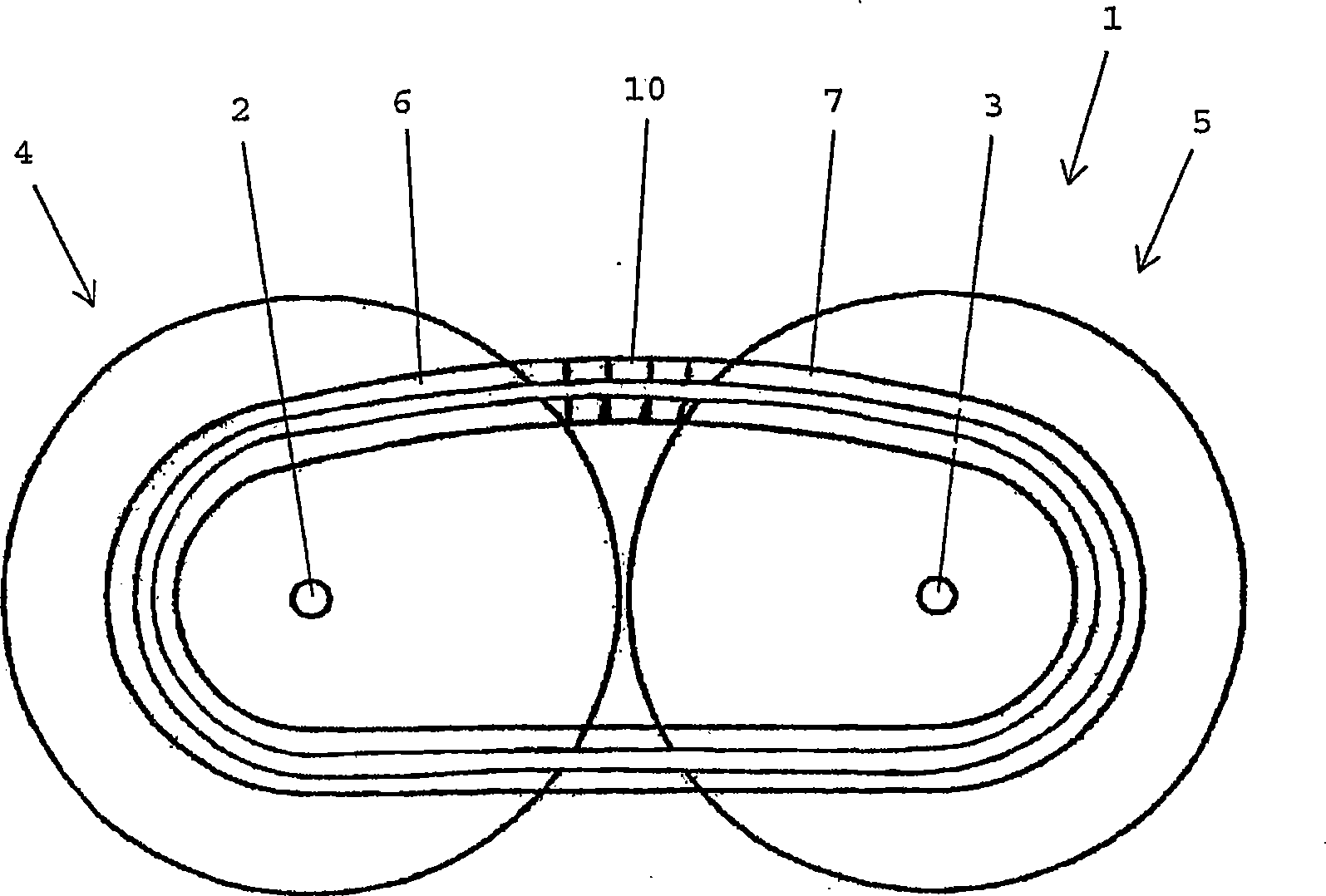

[0029] figure 1A continuously variable transmission is shown schematically, which is especially suitable for use in a motor vehicle. The continuously variable transmission is indicated generally by the reference numeral 1 .

[0030] The continuously variable transmission 1 comprises two pulleys 4 , 5 which are arranged on separate pulley shafts 2 , 3 . A continuous push belt 6 shaped as a closed loop is arranged around the pulleys 4 , 5 and serves to transmit torque between the pulley shafts 2 , 3 . Each pulley 4, 5 comprises two pulley sheaves (pulley sheave), wherein said pulley 6 is located and sandwiched between said two pulley sheaves, so that the force can be between the pulleys 4, 5 and The push belts 6 are transmitted by friction.

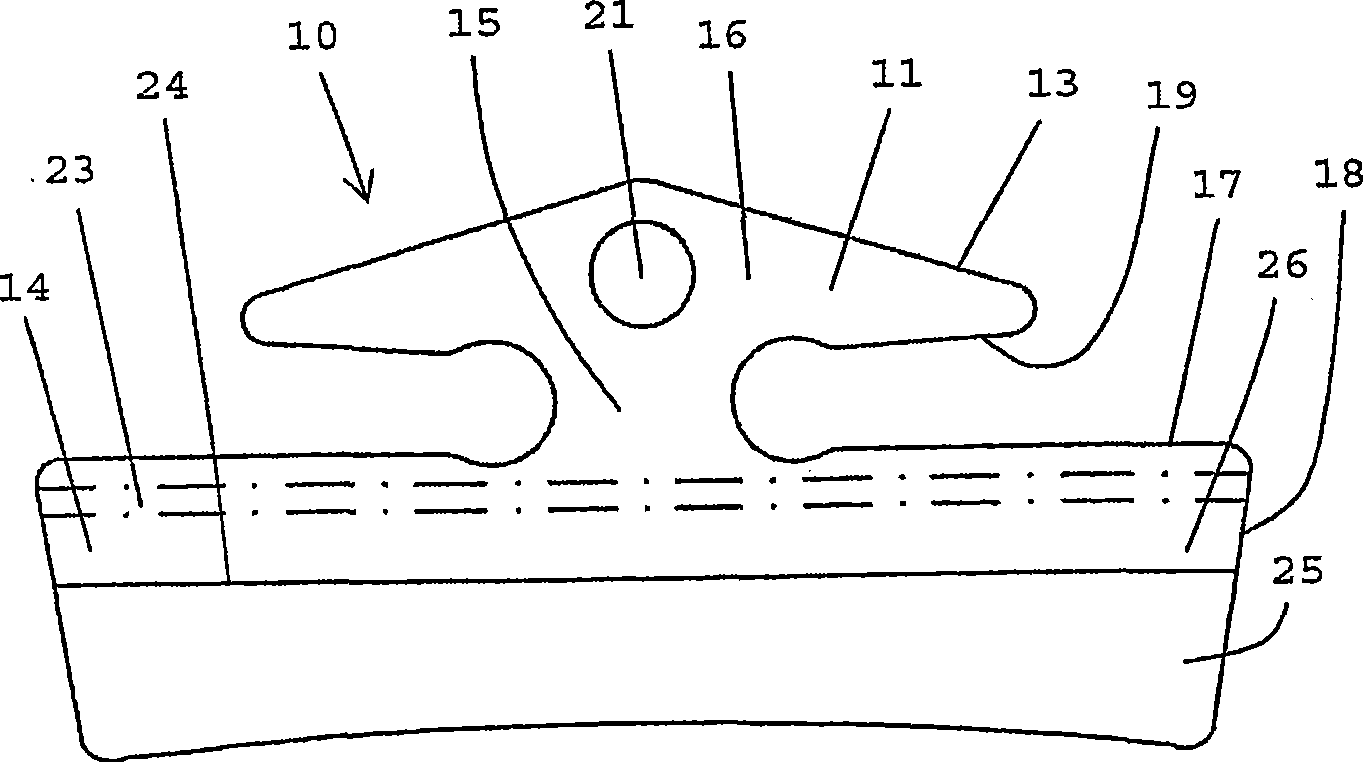

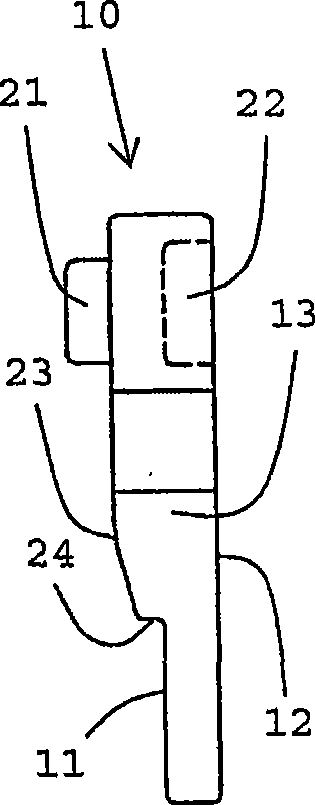

[0031] The push belt 6 comprises at least one continuous carrier 7 substantially comprising a plurality of loops. Transverse elements 10 are arranged along the entire length of the carrier 7 , each transverse element 10 being adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com