Engine generating set utilizing kinetic energy and wind energy

A power generation device and wind energy technology, applied in electromechanical devices, motors, electric vehicles, etc., can solve the problems of power that cannot output large energy, small motors, and low power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

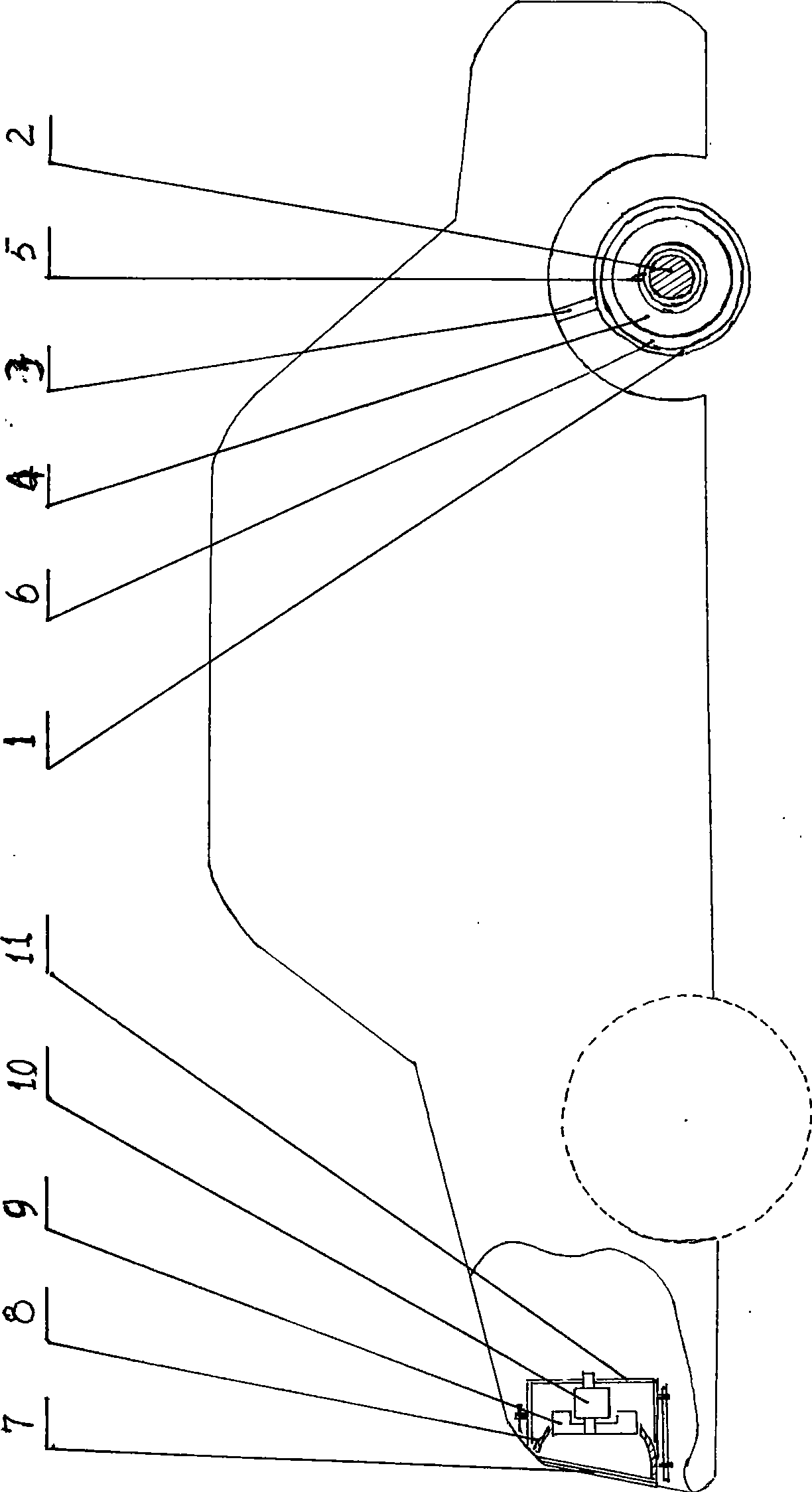

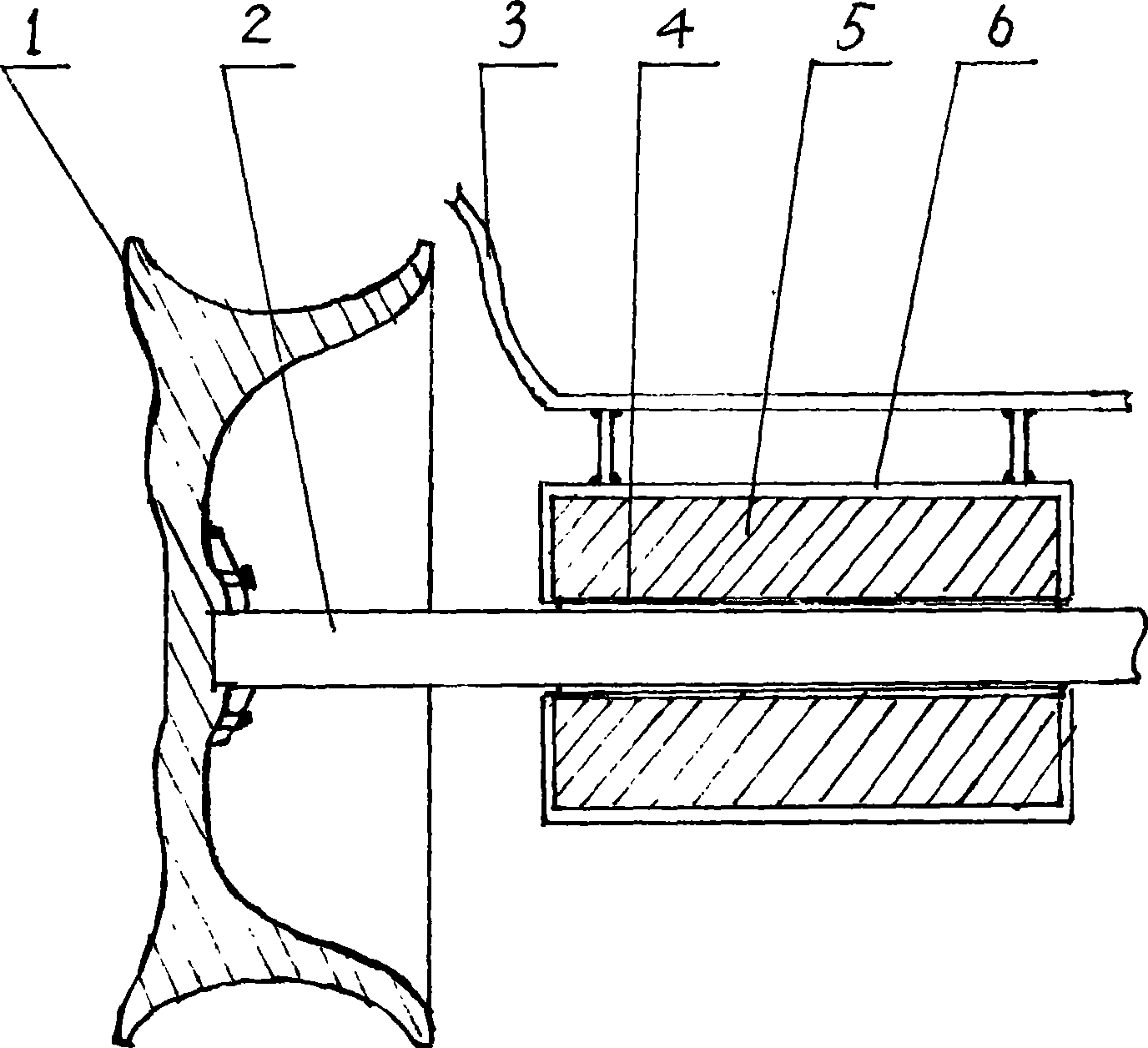

[0013] Example 1, see figure 1 , figure 2 , a motorized power generation device using kinetic energy and wind energy is composed of a hub 1, a wheel shaft 2, a stator coil 4, a rotor coil 5, a fan impeller 9, a generator 10, etc., and the stator coil is embedded in a stator 6 fixed on a support plate 3 On a neutral or non-rotating wheel shaft, the rotor coil is fixed on the wheel hub or the wheel shaft to form magnetic cutting and generate current. A fairing 8 is fixed behind the center grid 7 of the front of the car, and a fan impeller and a generator are installed behind the fairing. The generator is installed on bracket 11.

Embodiment 2

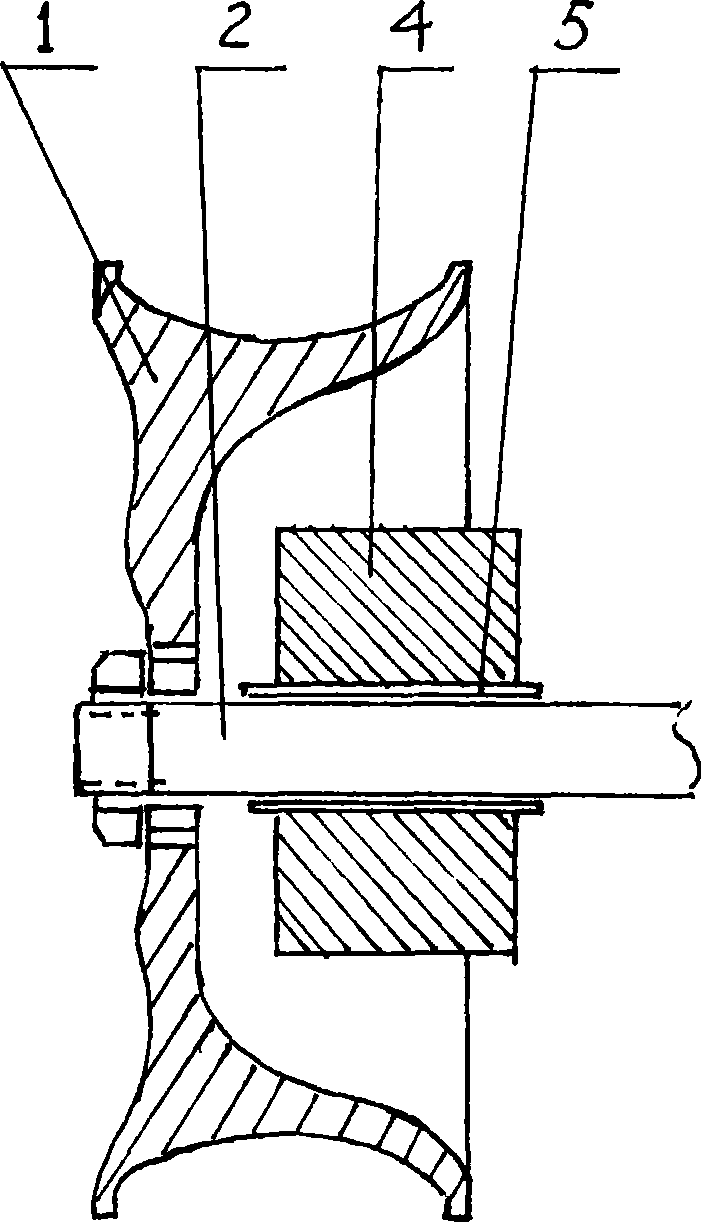

[0014] Example 2, see figure 1 , figure 2 , image 3 , a motorized power generation device using kinetic energy and wind energy is composed of a hub 1, a wheel shaft 2, a stator coil 4, a rotor coil 5, a fan impeller 9, a generator 10, etc., and the stator coil is embedded in a stator 6 fixed on a support plate 3 On a neutral or non-rotating wheel shaft, the rotor coil is fixed on the wheel hub or the wheel shaft to form magnetic cutting and generate current. A fairing 8 is fixed behind the center grid 7 of the front of the car, and a fan impeller and a generator are installed behind the fairing. The generator is installed On the bracket 11, the rotor coil of this embodiment is composed of multiple pieces of permanent magnets.

Embodiment 3

[0015] Example 3, see figure 1 , figure 2 , image 3 , a motorized power generation device using kinetic energy and wind energy is composed of a hub 1, a wheel shaft 2, a stator coil 4, a rotor coil 5, a fan impeller 9, a generator 10, etc., and the stator coil is embedded in a stator 6 fixed on a support plate 3 On a neutral or non-rotating wheel shaft, the rotor coil is fixed on the wheel hub or the wheel shaft to form magnetic cutting and generate current. A fairing 8 is fixed behind the center grid 7 of the front of the car, and a fan impeller and a generator are installed behind the fairing. The generator is installed On the bracket 11, in order to make better use of the rotation of the wheel hub, a fixed plate can be added on the inside of the wheel hub in this implementation, and a circular friction plate is fixed on the plate. The generator with the friction wheel is fixed on the support plate, and the friction wheel In contact with the friction plate, the generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com