Testing machine for mechanical parameter of roadbed material in freezing and thawing cycle

A technology of mechanical parameters and freeze-thaw cycles, applied in the direction of material inspection products, analytical materials, measuring devices, etc., can solve the problems of not being able to test the mechanical indicators of roadbed materials and the changes of material mechanical indicators, so as to improve the testing accuracy, The effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

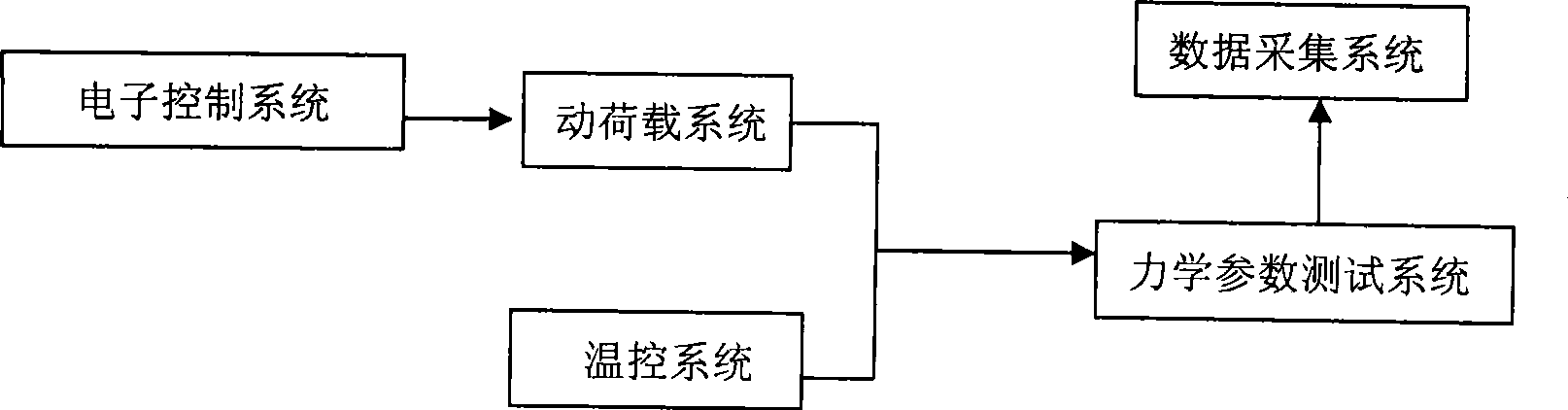

[0011] refer to figure 1 , the present invention includes a temperature control system, a dynamic load system, a mechanical parameter testing system, a data acquisition system and an electronic control system. The temperature control system is used to simulate the freeze-thaw cycle of subgrade soil in a real environment, and the electronic The control system controls the dynamic load system so that the dynamic load system outputs simulated traffic loads of different frequencies, and the total settlement and strain are measured by the mechanical parameter test system. The deformation and strain values are collected in real time by the data acquisition system and processed Display values and time-displacement curves, strain-time curves.

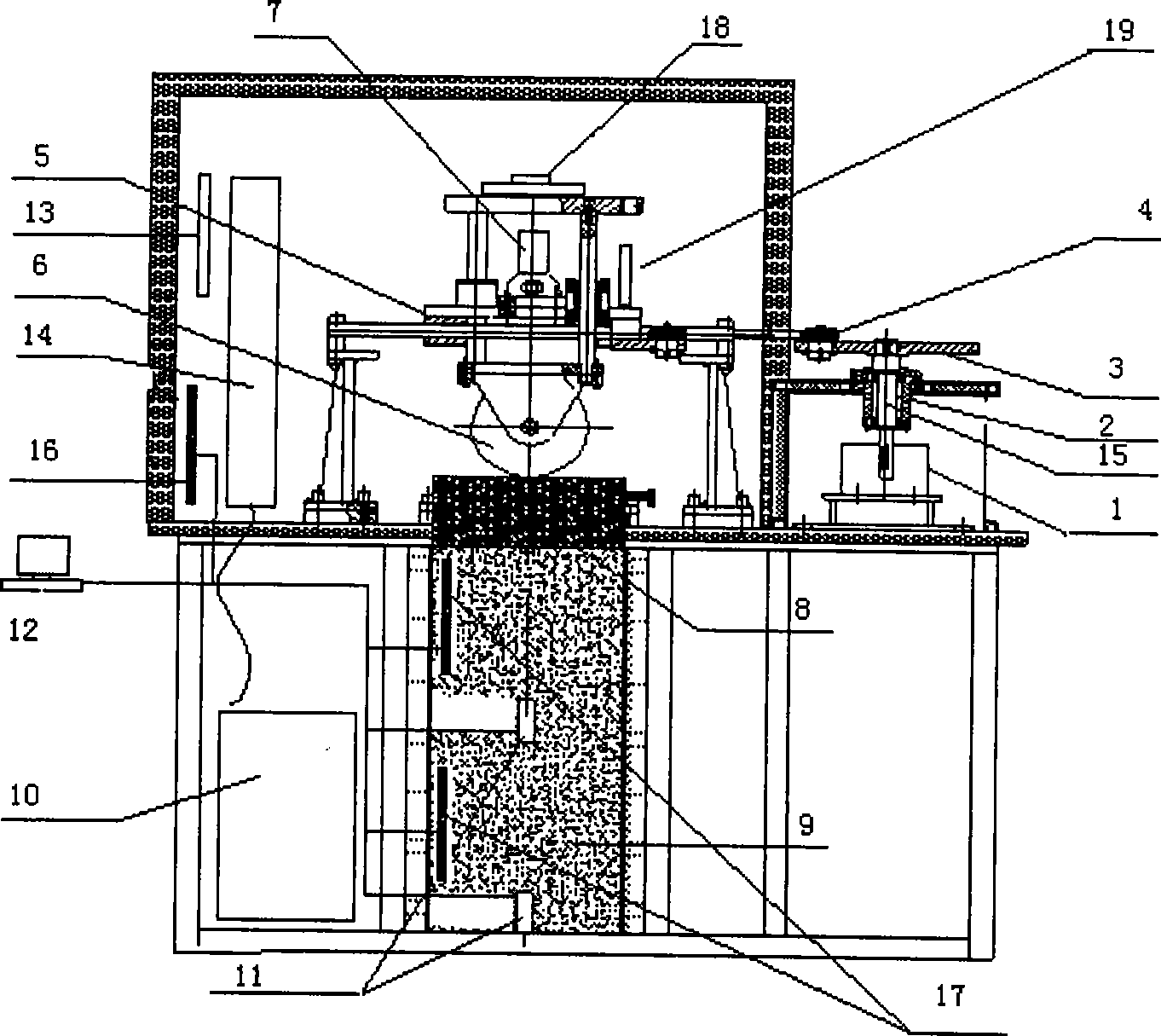

[0012] refer to figure 2 , the dynamic load system of the present invention is driven by the output power of the motor and the reducer 1, the frequency converter 2 connected to the rotating shaft 15 changes the frequency of the power, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com