Independent switch of lifter for vehicle windscreen

A technology for automotive glass and lifters, applied in electrical switches, electrical components, circuits, etc., can solve problems such as reducing product volume, and achieve the effects of improving quality, compact and exquisite overall structure, and quick and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

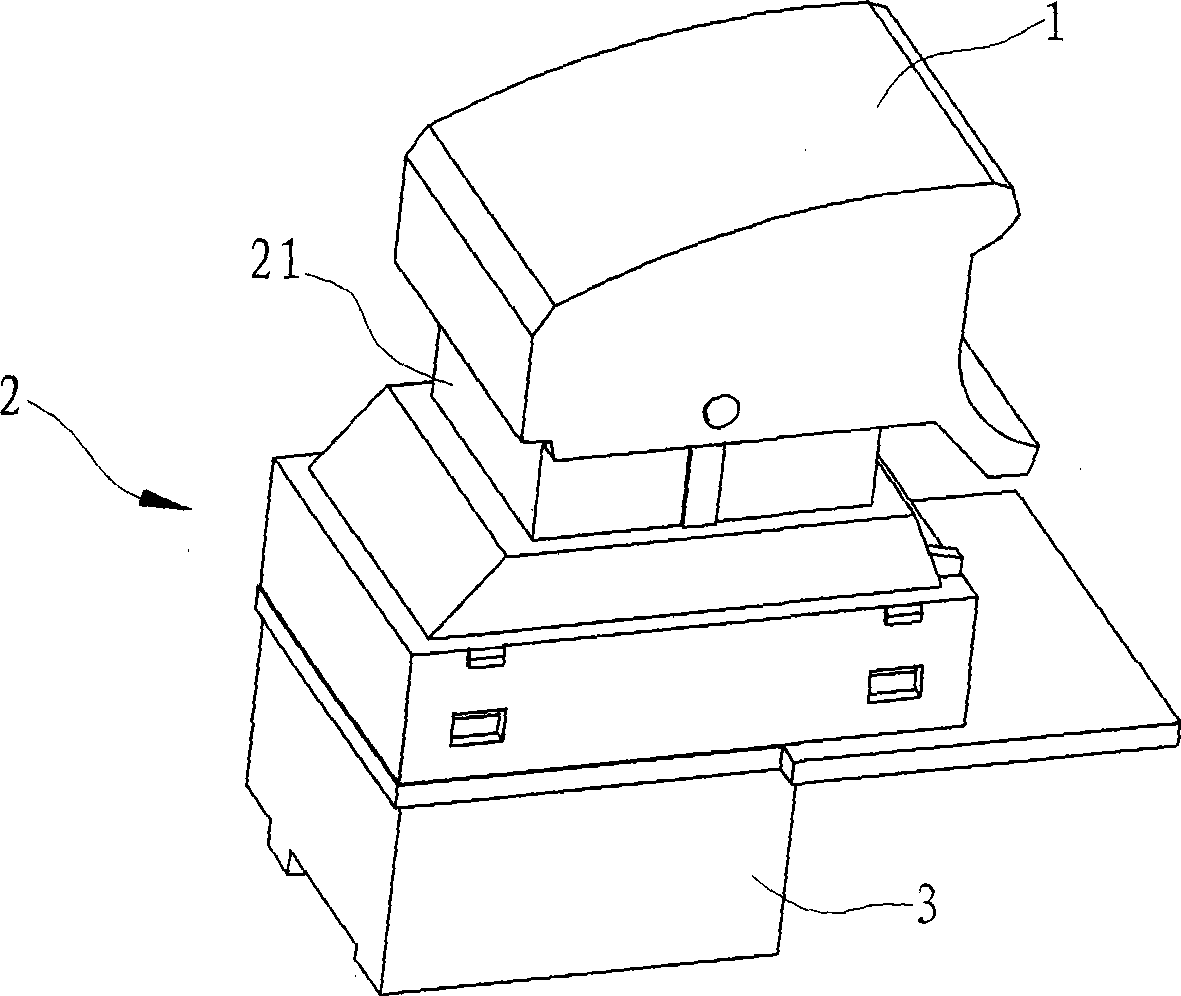

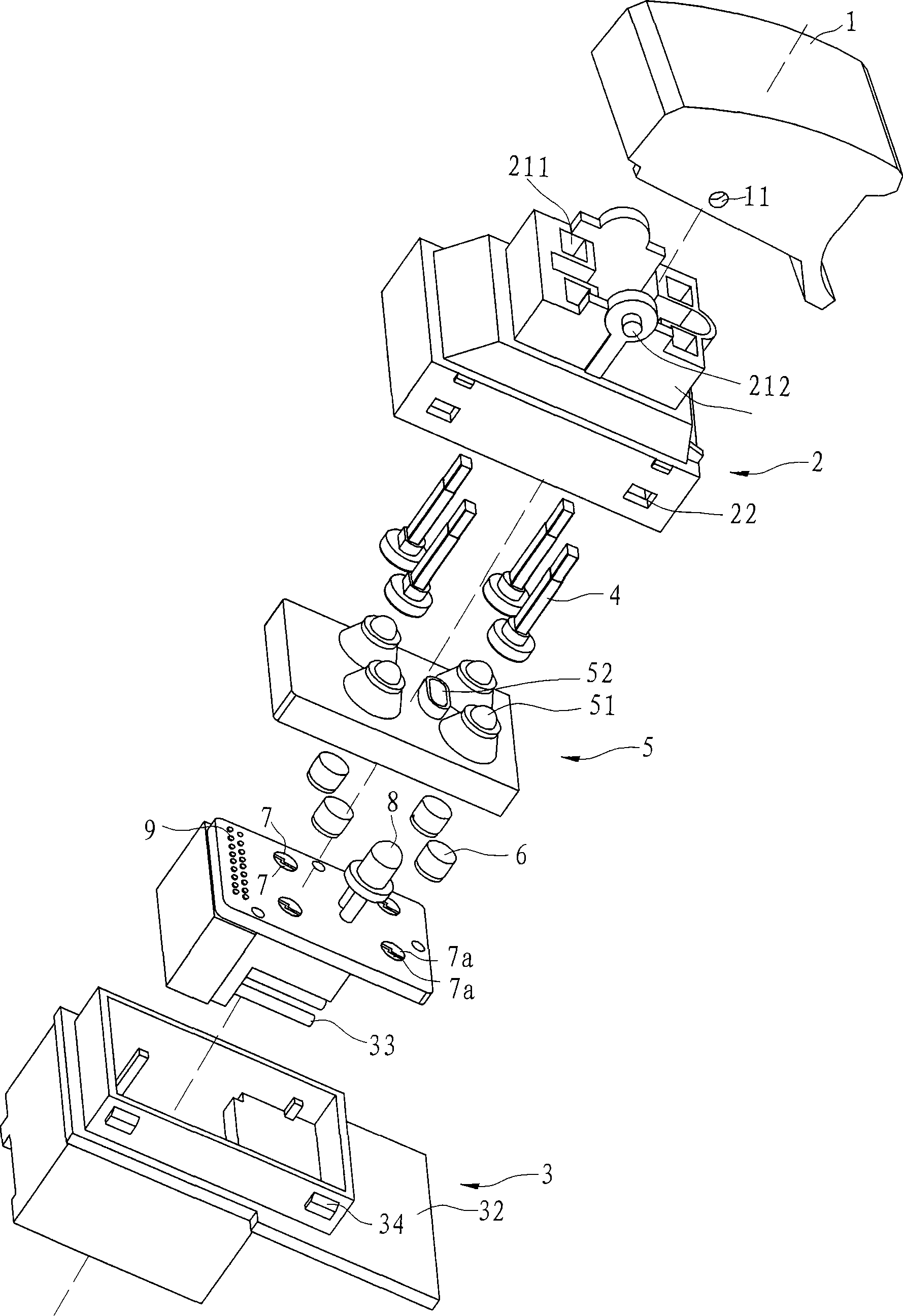

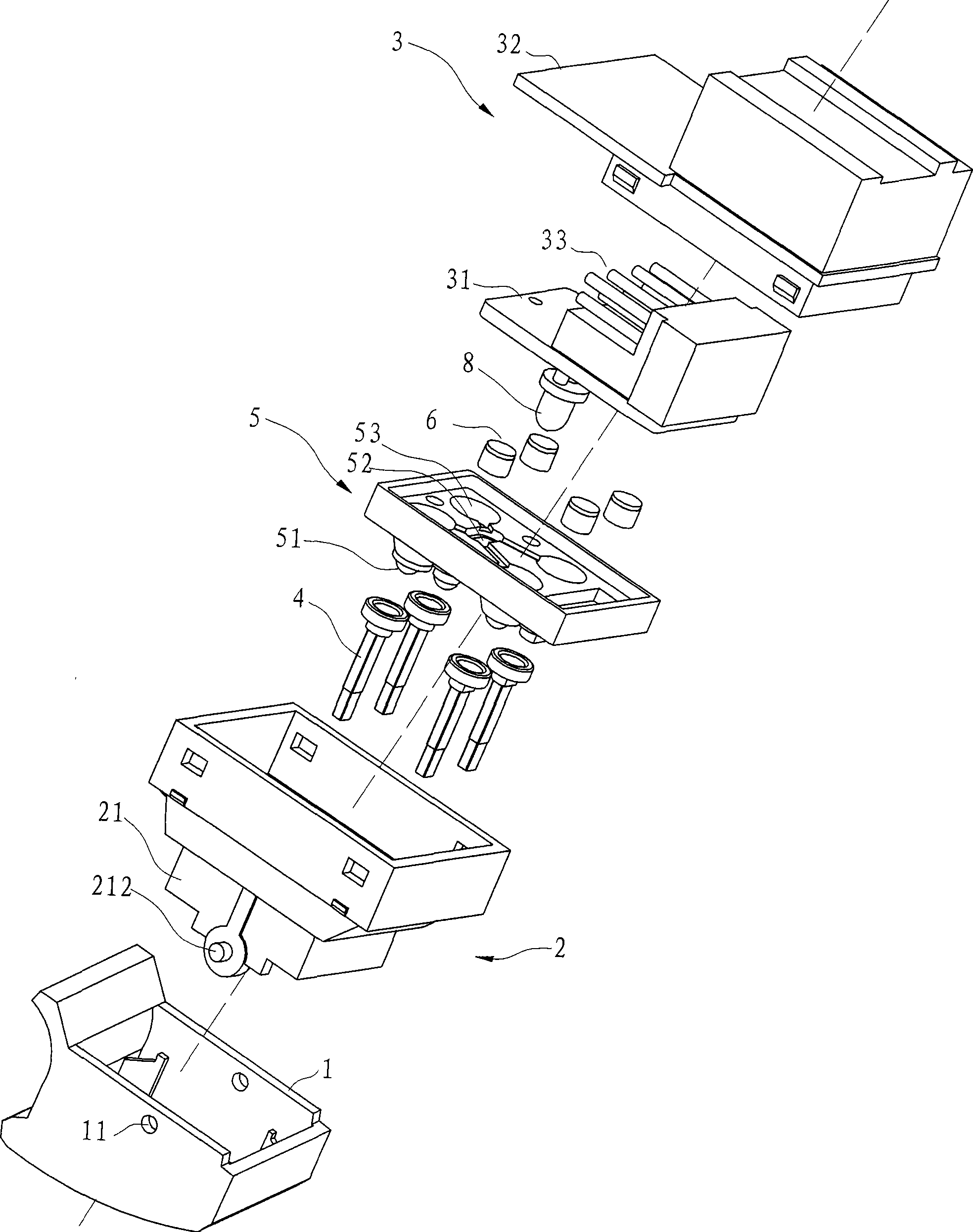

[0022] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment is a preferred embodiment of the present invention. The independent automobile window regulator switch in the present embodiment includes a base 3, a top pin 4, a movable contact piece 6, an elastic insulating member 5, a housing 2 and a button 1 .

[0023] The base 3 includes a bracket 32 and a circuit board 31 on which two pairs of the first static contacts 7 and two pairs of the second static contacts 7a are installed. The lower end surface of the circuit board 31 has a Conducted pin 33, the first static contact piece 7 is used to control the rise of the glass lifter, and the second static contact piece 7a is used to control the lowering of the glass lifter, each pair of the first static contact piece 7 and the second static contact piece 7a disconnected from each other, two pairs of first static contact pieces 7 are arranged in parallel and connected in parallel wit...

Embodiment 2

[0029] Example 2, such as Figure 6 and Figure 7 As shown, the bottom of the ejector pin 4 of the independent automotive window regulator switch in this embodiment has a cylindrical pressure block 41a, and correspondingly, the upper end surface of the elastic insulating member 5 has a pressure groove 51a that cooperates with the pressure block 41a. If the cylinder fits, Guidance is worse than spherical fit.

[0030] The elastic insulating member 5 is flush with the circuit board 31 , and does not cover the entire circuit board 31 , so that the soldering feet 9 are exposed. The elastic insulating member 5 in this embodiment has two functions, first, as a transmission member between a movable contact piece and the ejector pin; second, as a reset member of the ejector pin, because it has certain elasticity.

[0031] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com