Stacked packaging structure

A packaging structure, stacking technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problem that the single-chip packaging technology cannot meet the demand and other problems, achieve a small number, a large area, and overcome the cold junction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

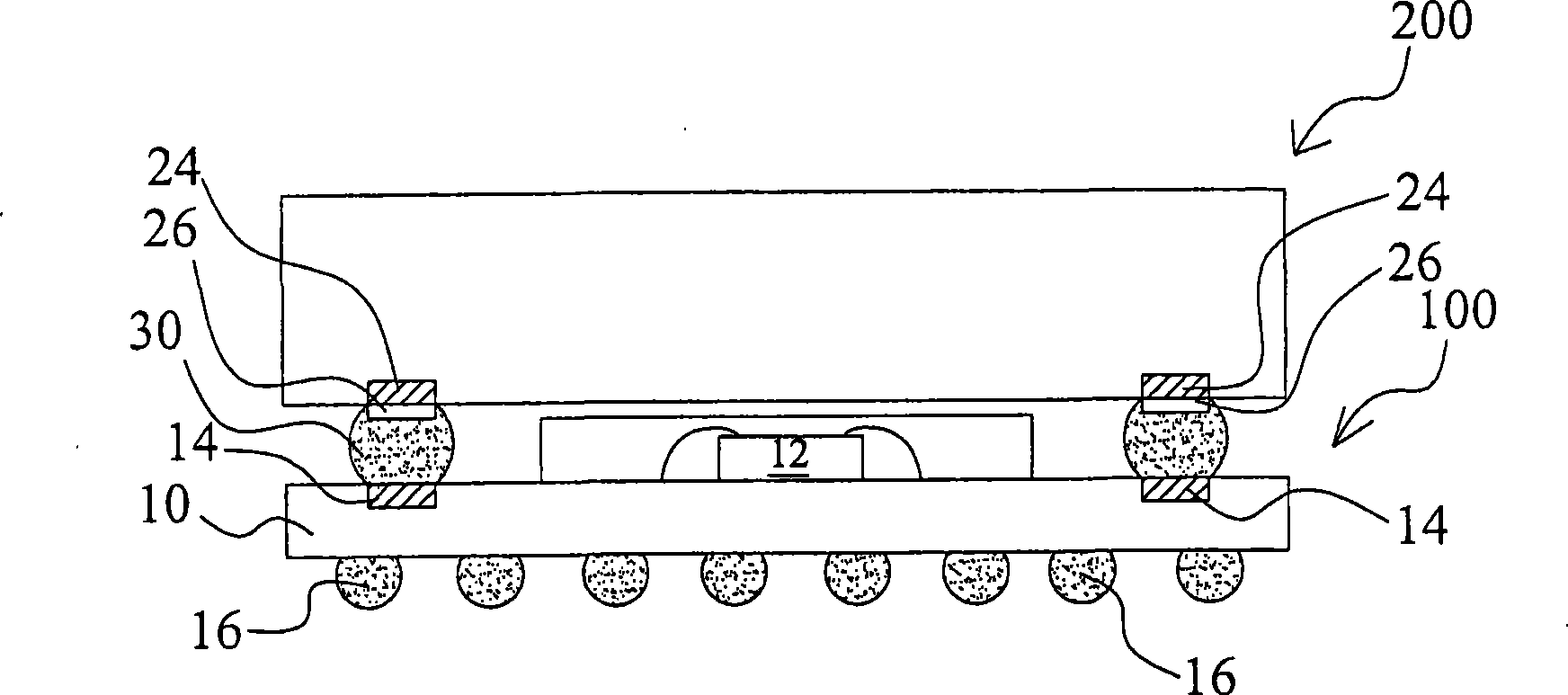

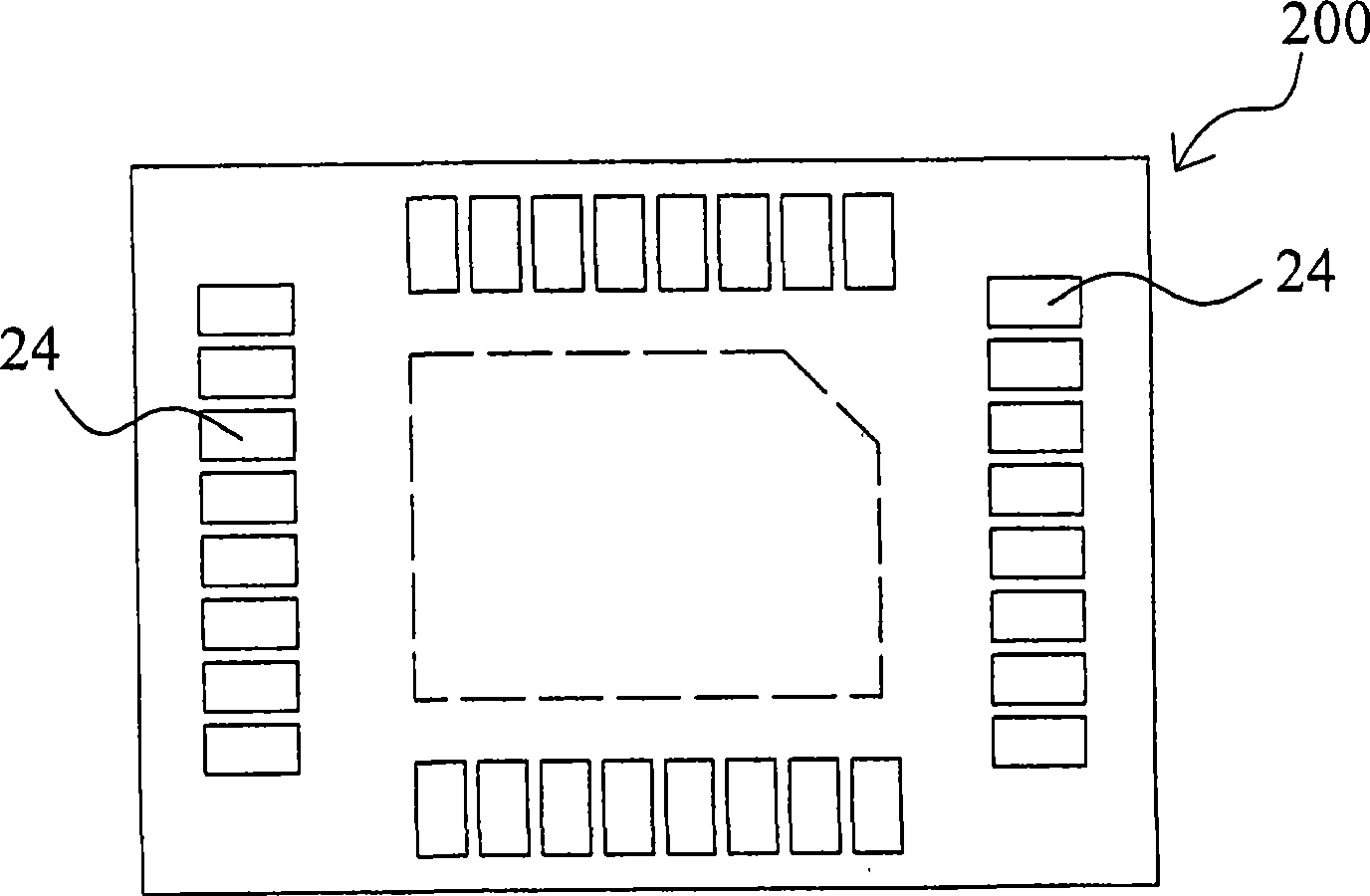

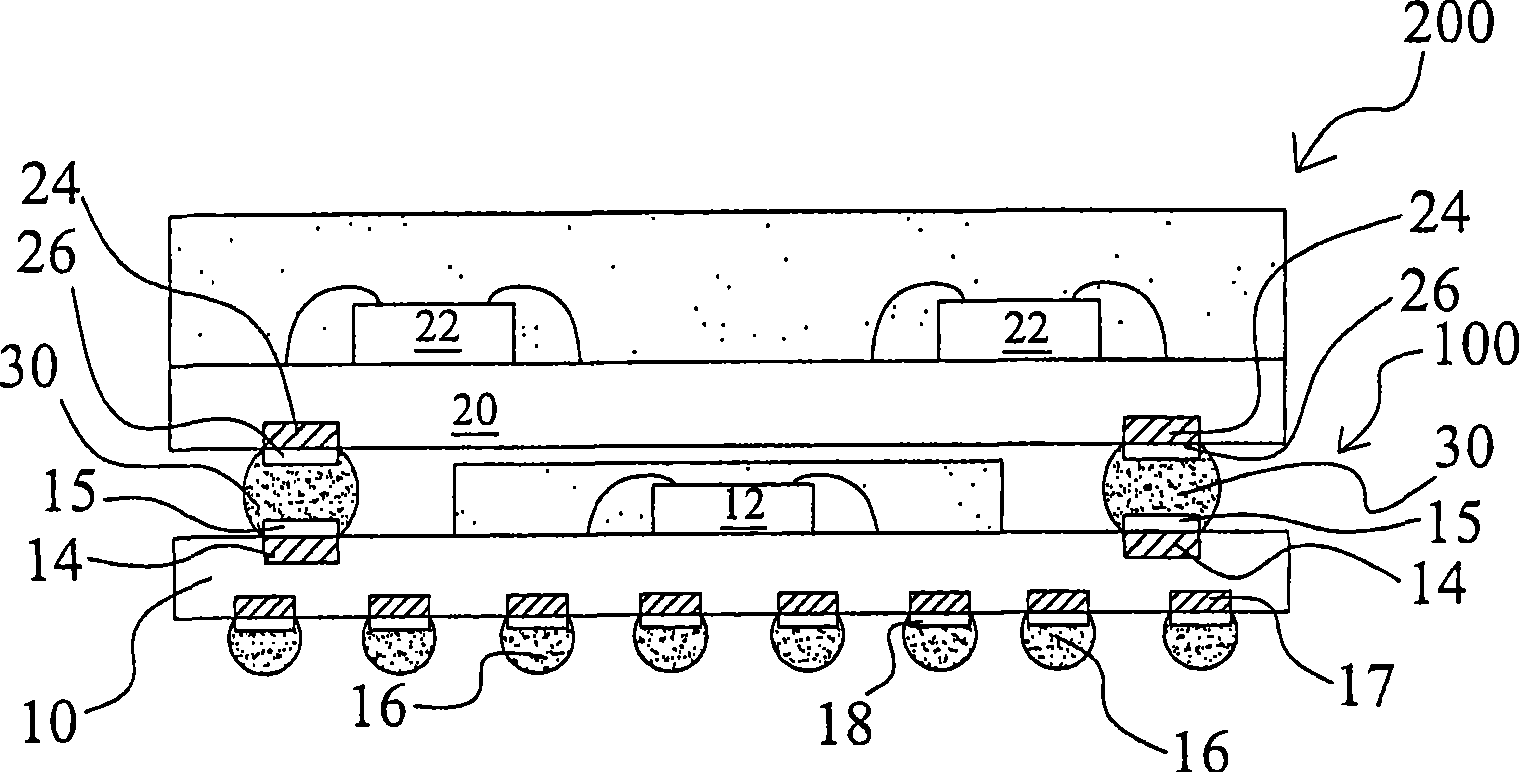

[0027] figure 1 Shown is a schematic diagram according to an embodiment of the present invention. In this embodiment, the package-on-package structure includes: a first package body 100 ; a plurality of second conductive solder balls 30 ; and a second package body 200 . The second package body 100 is stacked on the first package body 100 by using the second conductive solder balls 30 .

[0028] Such as figure 1 As shown, the first package 100 is a ball grid array package. The first package 100 includes a first substrate 10 having an upper surface and a lower surface. At least one first chip 12 is disposed on the upper surface of the first substrate 10 . A plurality of first conductive pads 14 are disposed and exposed on the upper surface of the first substrate 10 ; and a plurality of first conductive solder balls 16 are disposed on the lower surface of the first substrate. The second conductive solder ball 30 is disposed on the first conductive pad 14 .

[0029] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com