Pantograph especially for harbor

A pantograph and port technology, applied in the field of trackless mobile equipment, can solve problems such as high maintenance costs, high cost, and environmental pollution, and achieve high energy efficiency ratio and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

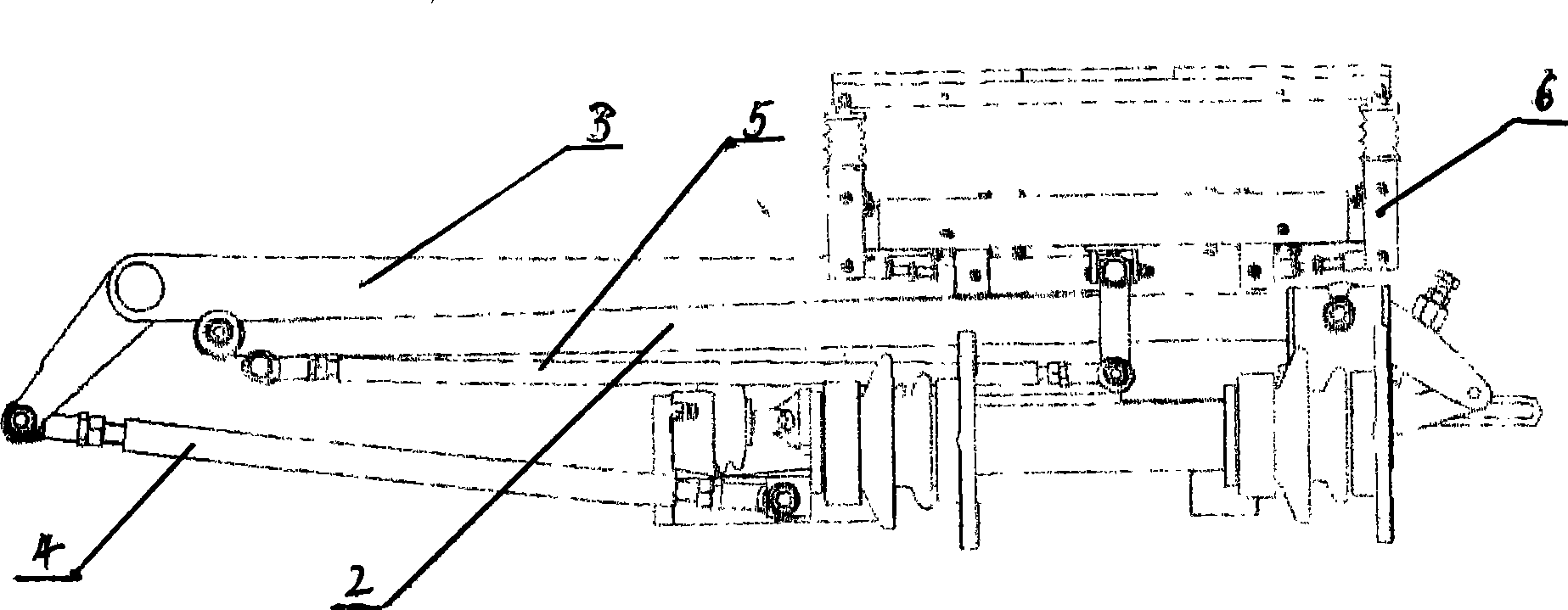

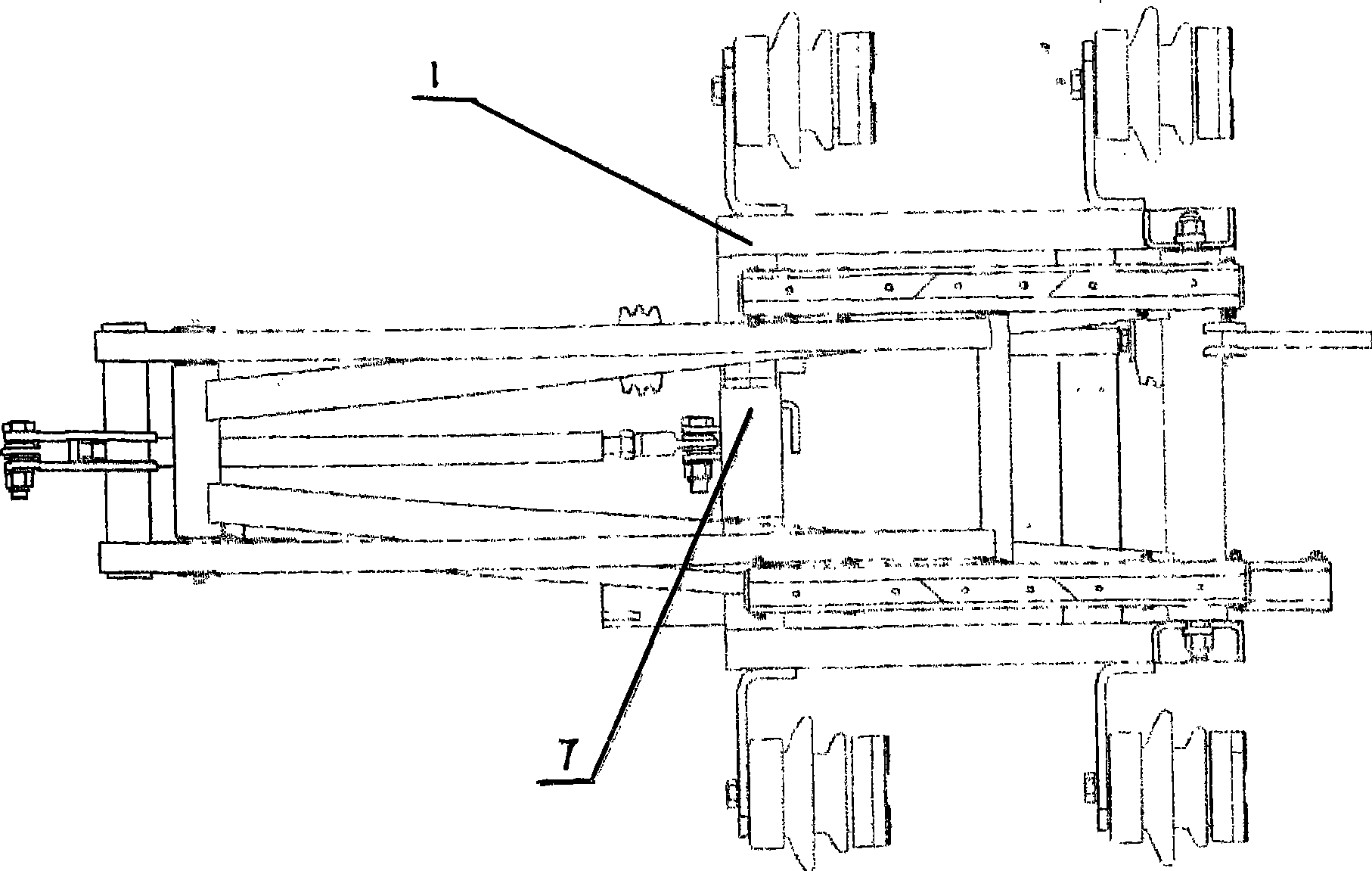

[0015] like figure 1 As shown, the underframe 1 is the base of the present invention, the lower end of the lower arm 2 is connected with the underframe 1 by bolts, the upper end of the lower arm 2 is connected with the lower arm 2 by bolts, and the upper and lower ends of the lower arm 2 are connected by bolts. The rotation is connected by bearing transition, the lower end of upper arm 3 and lower arm 2 are connected by bolts, and are transitionally connected by bearings, the upper end of upper arm 3 and bow head 6 are connected by bolts, and transitioned by polytetrafluoroethylene sleeves connect. Pull rod 4 is a coupling part, and the upper and lower ends of pull rod 4 are connected with upper machine arm 3 and underframe 1 respectively by bolts, and the rotation of the upper and lower ends of pull rod 4 is connected by bearing transition. The balance bar 5 is also a connecting part. The upper and lower ends of the balance bar 5 are connected with the bow head 6 and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com