Regular hexagon all-electric melting tank furnace for melting medium-alkali glass

A regular hexagonal, all-electric melting technology, used in electric furnaces, furnaces, retort furnaces, etc., can solve problems such as unreasonable distribution of power lines, unreasonable electrode arrangement and power distribution, and difficulty in controlling furnace temperature, so as to reduce erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

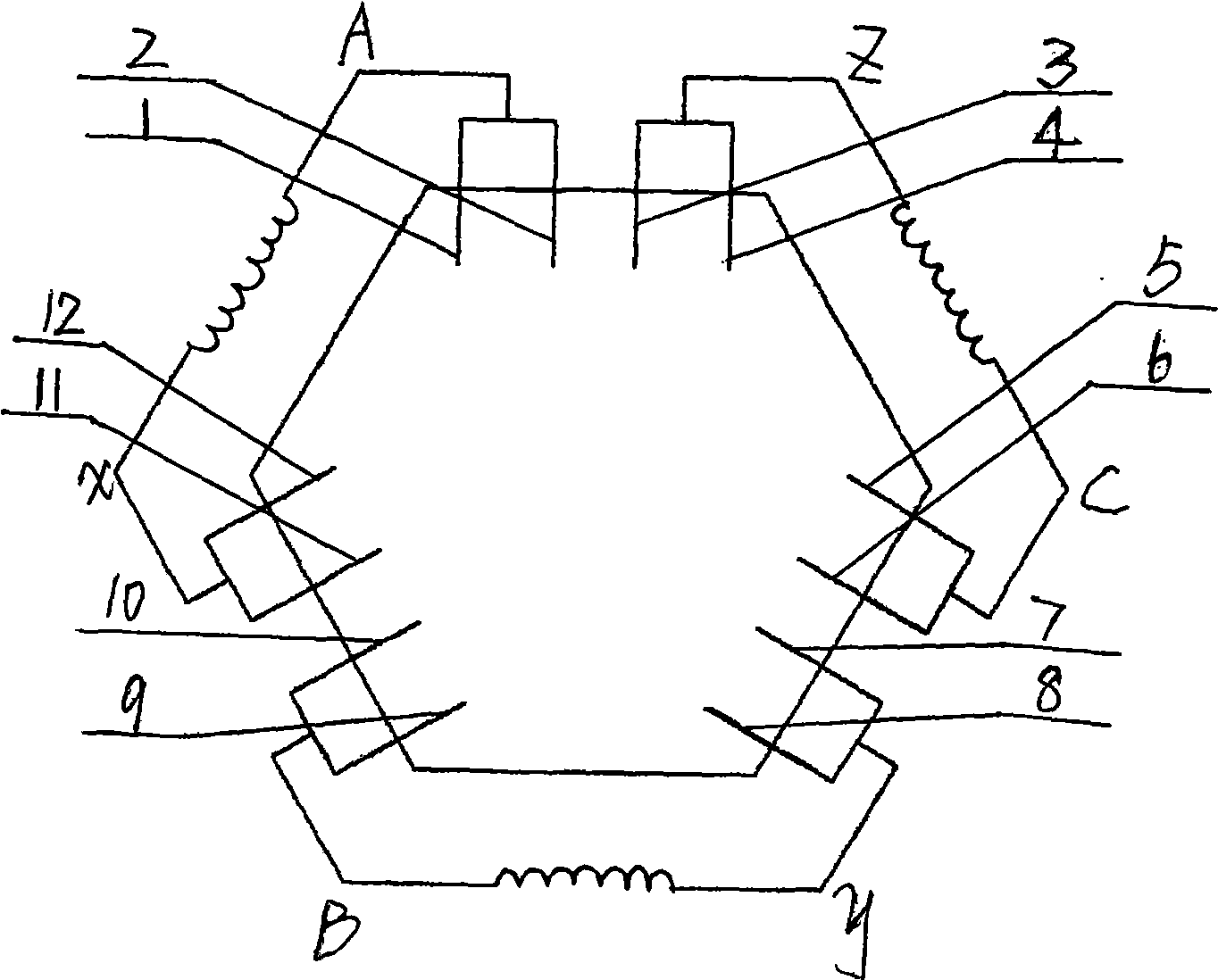

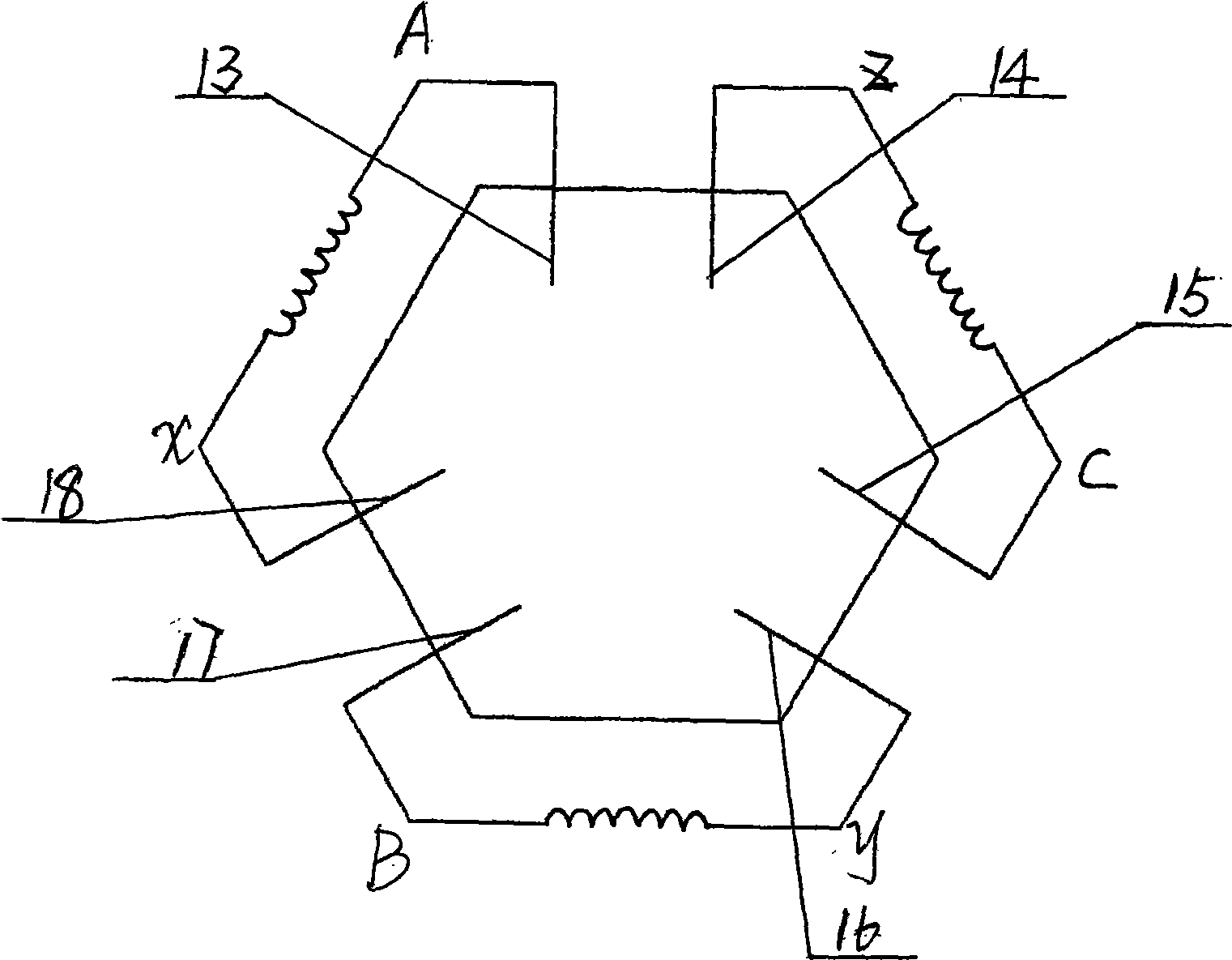

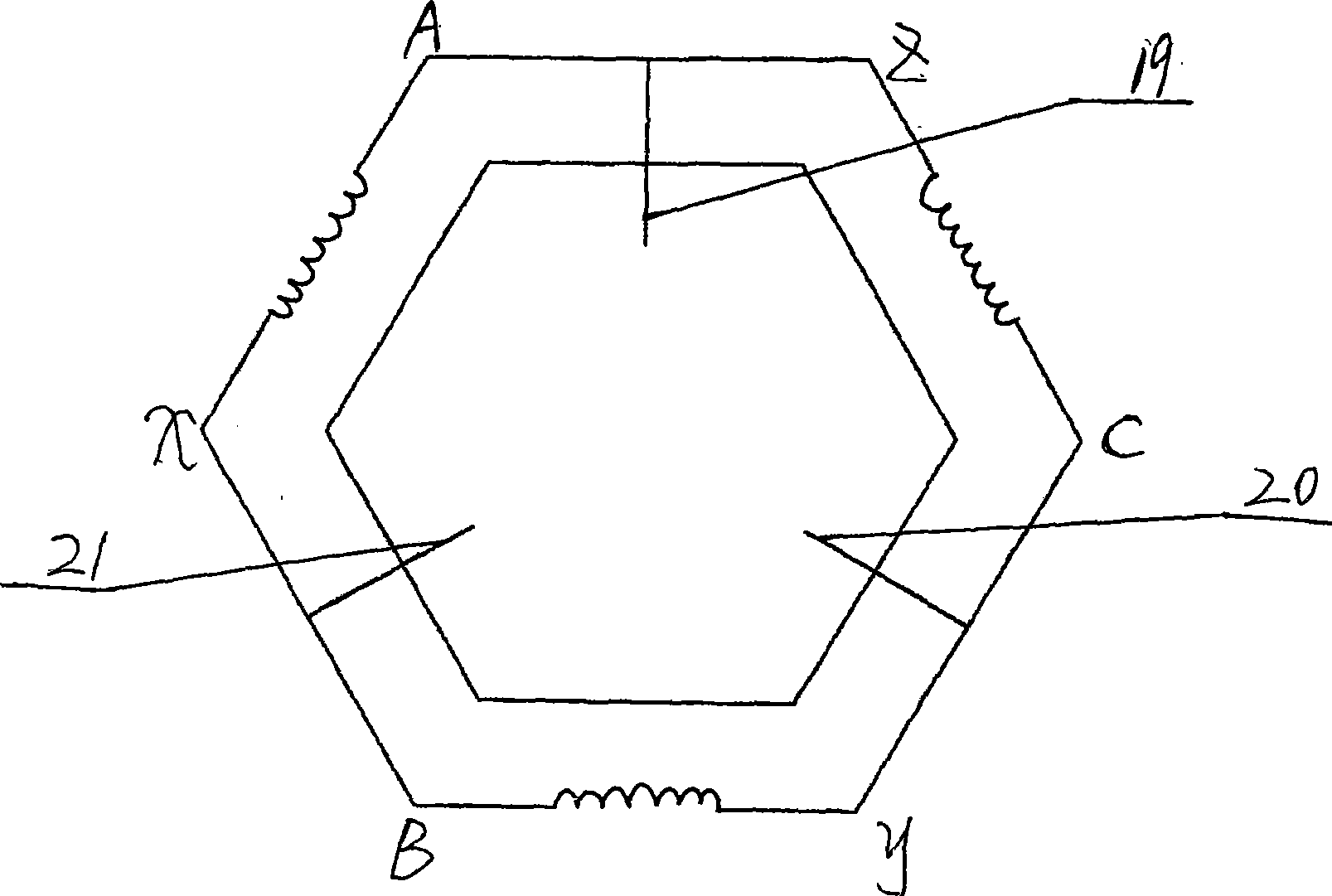

[0014] figure 1 Shown is the arrangement of the upper electrodes of the regular hexagonal all-electric melting pool furnace for melting medium-alkali glass. There are 12 upper electrodes in total, and 4 electrodes are located on the sides of the three symmetrical furnace walls. Electrode 1 and Electrode 2 form a group ; electrode 3 and electrode 4 as a group; electrode 5 and electrode 6 as a group; electrode 7 and electrode 8 as a group; electrode 9 and electrode 10 as a group; electrode 11 and electrode 12 as a group; electrodes in the group parallel connection

[0015] The parallel connection of electrode 1 and electrode 2 and the parallel connection of electrode 11 and electrode 12 are according to the AX winding of the magnetic voltage regulator.

[0016] The parallel electrode of electrode 3 and electrode 4 and the parallel electrode of electrode 5 and electrode 6 are connected to the CZ winding of the magnetic voltage regulator.

[0017] The parallel connection of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com