Red mud unburned brick and preparation thereof

A technology of avoiding burning bricks and red mud, which is applied in the field of building materials, can solve the problems of increased viscosity of slag, unfavorable cement production, high energy consumption for dehydration, etc., and achieve the effect of reducing radioactive hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

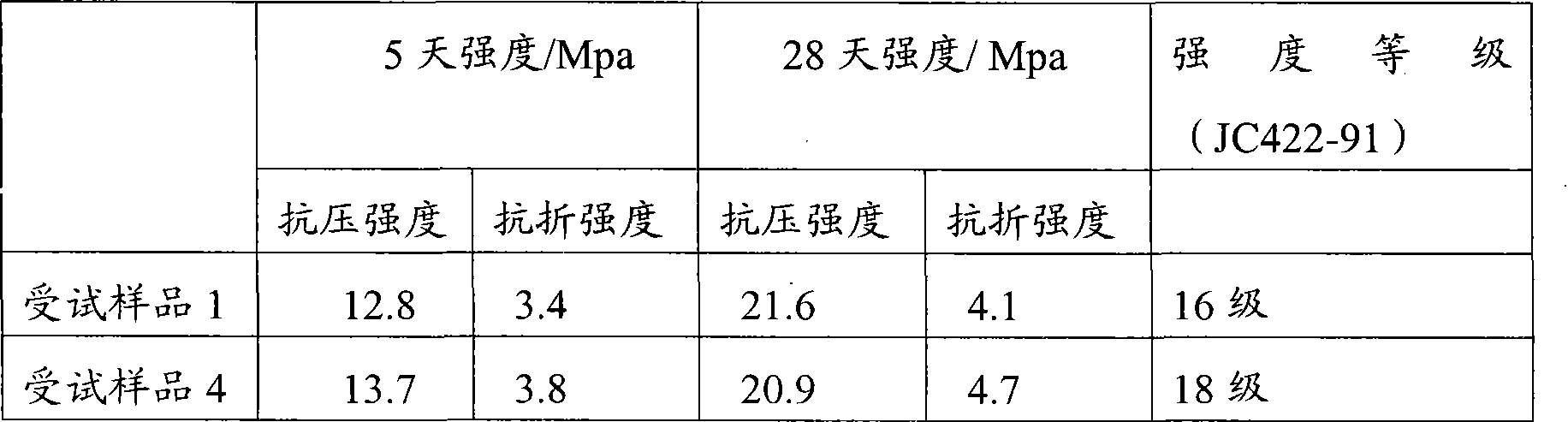

[0026] Example 1 Preparation of red mud non-burning brick

[0027] Take the components according to the following weights: dry red mud 8; fly ash 24, quartz sand (the particle size is controlled below 10 mm) 25, lime 8, gypsum 3, cement 1, magnesium sulfate 0.0002;

[0028] Crush the red mud to control the particle size to be less than 10mm; crush the gypsum into fine powder and pass through a 160-200 mesh sieve; crush the quartz sand to fine powder to control the particle size to be less than 10mm;

[0029] After mixing the red mud, fly ash, quartz sand, lime, gypsum and magnesium sulfate together, use a bucket elevator to lift it and then use a wheel mill to mix it evenly, aging, and then add cement and a certain amount of Stir evenly with water (control the water content between 10-15%), press to shape, spray water for curing at room temperature for 28 days, and get it.

Example Embodiment

[0030] Example 2 Preparation of red mud non-burning brick

[0031] Take each component according to the following weight: dry red mud 25; fly ash 30, crushed stone powder (the particle size is controlled below 10mm) 30, lime 12, gypsum 5, cement 3, magnesium sulfate 0.0005;

[0032] Crush the dry red mud to control the particle size to be less than 10mm; crush the gypsum into fine powder and pass through a 160-200 mesh sieve; crush the crushed stone powder to control the particle size to be less than 10mm;

[0033] After mixing the dry red mud, fly ash, crushed stone powder, lime, gypsum and magnesium sulfate, it is lifted by a bucket elevator and then stirred evenly by a wheel milling method, aging treatment, and then cement and a certain amount are added. After mixing a large amount of water (control the water content between 10-15%), stir evenly, press to form, keep the pressure at a steam pressure of 1.2Mpa for 4 hours, store for 7 days after steaming and leave the factory, re...

Example Embodiment

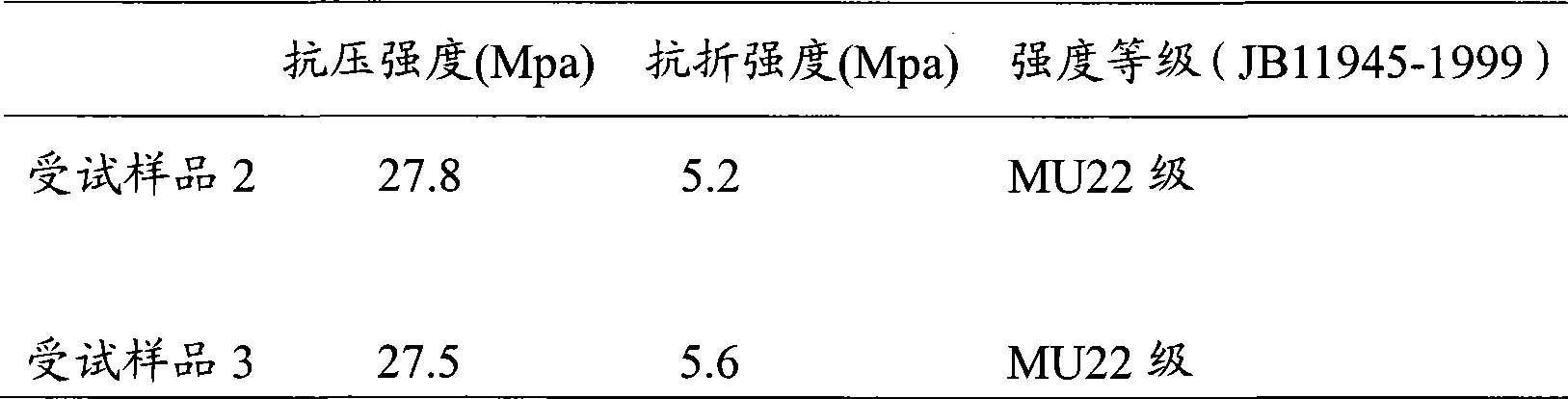

[0034] Example 3 Preparation of Red Mud Burn-free Brick

[0035] Take the components according to the following weights: dry red mud 3.5, wet red mud 21.5; fly ash 30, quartz sand (the particle size is controlled below 10mm) 30, lime 12, gypsum 5, cement 3, magnesium sulfate 0.0005;

[0036] Crush the red mud to control the particle size to be less than 10mm; crush the gypsum into fine powder and pass through a 160-200 mesh sieve; crush the crushed stone powder to fine powder to control the particle size to be less than 10mm;

[0037] After mixing the red mud, fly ash, crushed stone powder, lime, gypsum and magnesium sulfate, it is lifted by a bucket elevator and then stirred evenly by a wheel milling method, aging treatment, and then cement and a certain amount are added. After mixing a large amount of water (control the water content between 10-15%), stir evenly, press to form, keep the pressure at a steam pressure of 1.2Mpa for 4 hours, store for 7 days after steaming and leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com