Device used for making large-area radioactive source

A radioactive source and large-area technology, applied in the field of radioactive source preparation, can solve the problems of low electroplating efficiency, easy splashing, no public radioactive source preparation methods and devices used, etc., and achieve the effect of keeping the parallelism unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

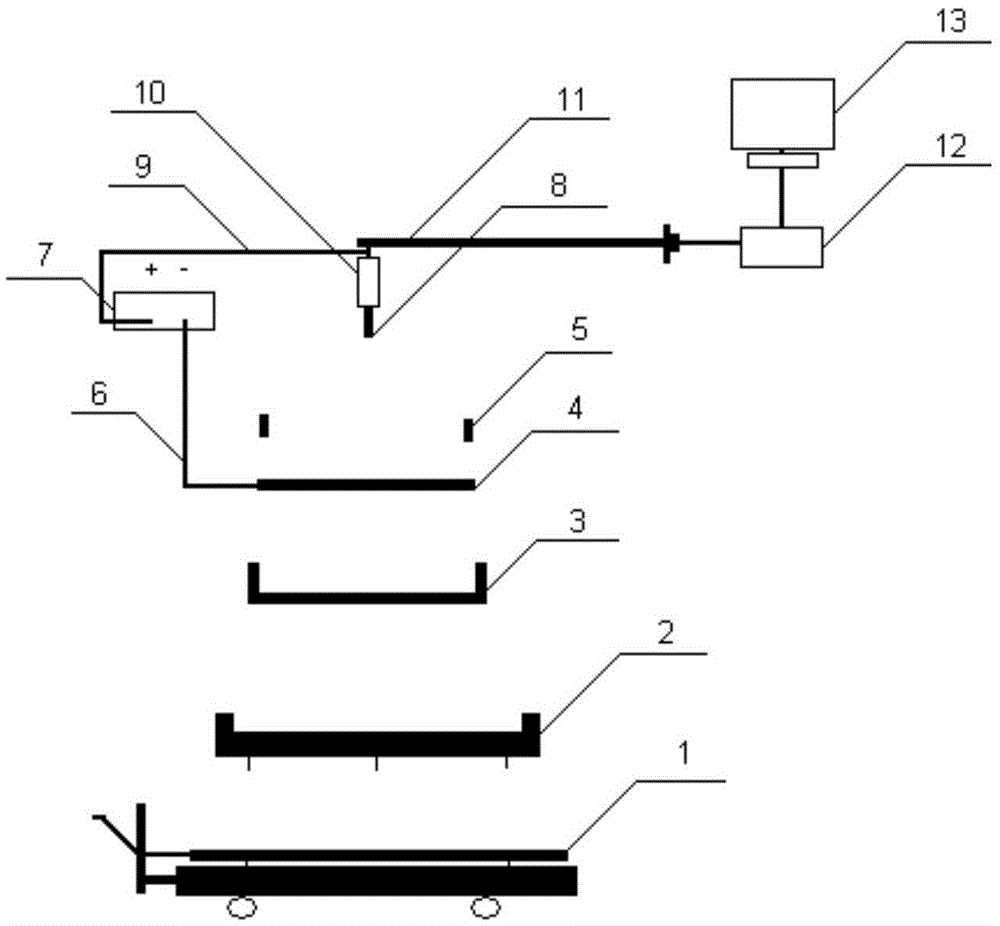

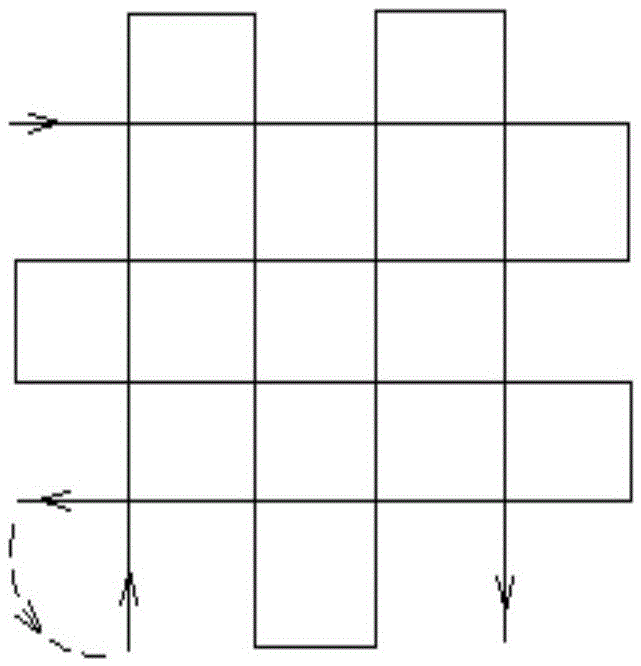

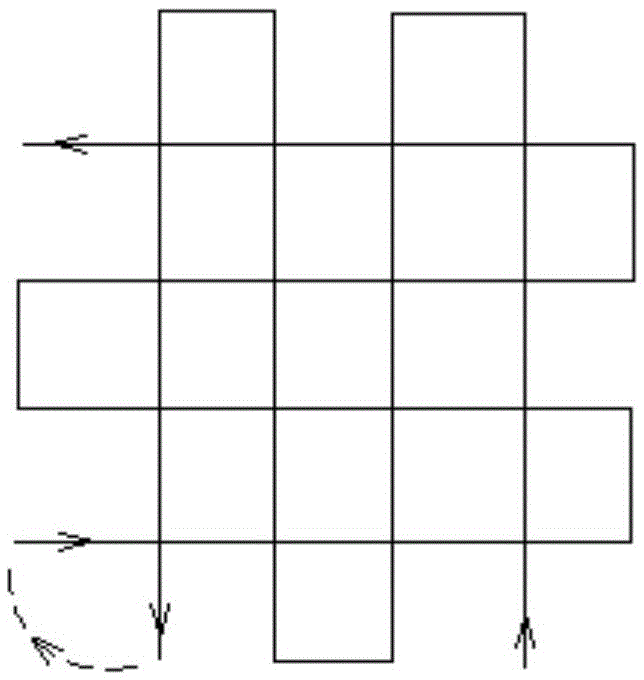

[0028] A device for preparing large-area radioactive sources. The device mainly includes a lifting platform car, an adjusting platform, a plating tank, a plating sheet, a plating solution protection frame, a Sanheng multi-purpose electrophoresis instrument power supply, a plating pen, a plating pen bracket, and two Dimensional translation device, controller and computer, wherein the bottom of the lifting platform vehicle is provided with rollers, the body is provided with a rectangular lifting plate, and one side of the lifting platform vehicle is provided with a handle and a pedal, pressing the handle can realize the lifting plate Ascending, stepping on the pedals can realize the descending of the lifting plate; the adjusting platform is placed above the lifting plate, and the bottom of the adjusting platform is provided with adjusting feet that can be finely adjusted in height; the plating tank is in the shape of a cuboid with an upper opening, located above the adjusting plat...

Embodiment 2

[0046] Different from Example 1, the device also includes a gauge block, which is in the shape of a cuboid with scales arranged on it; the distance between the lower end of the plating pen and the plated sheet can be precisely controlled by using the gauge block, and it can assist in adjusting the platform for plating. slices for leveling.

Embodiment 3

[0048] The difference from Example 1 is that the height of the plating solution protection frame is 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com