Environmentally friendly graphite gypsum board and preparation method thereof

A technology of gypsum board and graphite, which is applied in the field of building materials, can solve the problems that the distribution uniformity of fiber reinforcement is difficult to achieve the ideal level, the strength of gypsum board is limited, and the short fibers are difficult to be mixed evenly, so as to meet the requirements of human comfort, The effect of reducing the self-weight of the wall and increasing the usable area of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

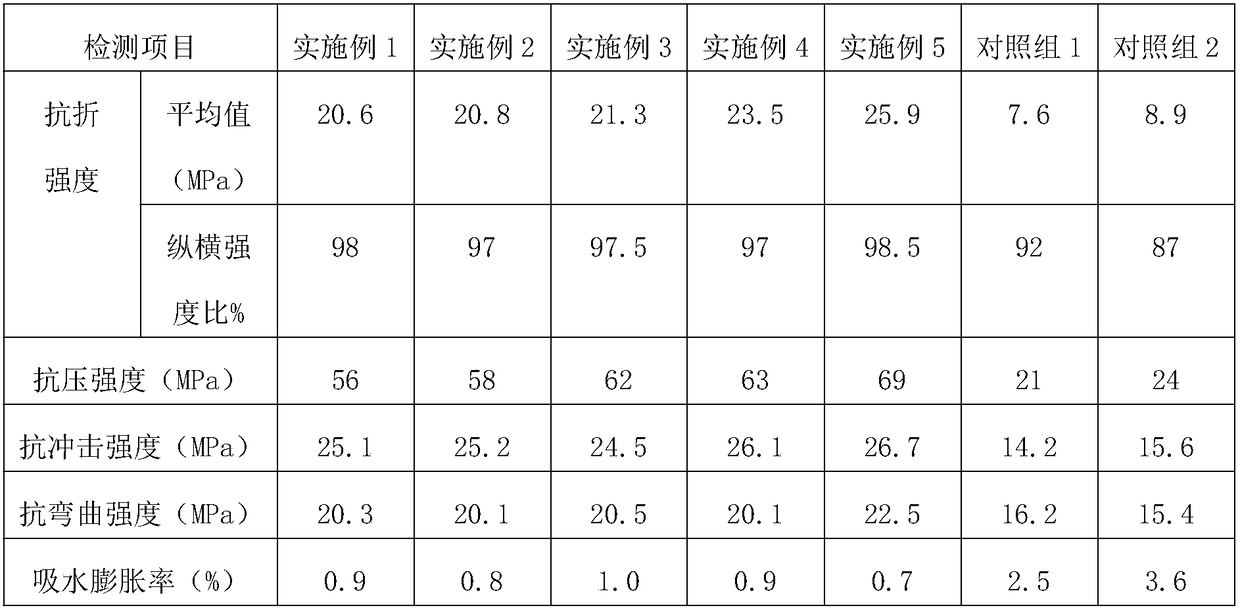

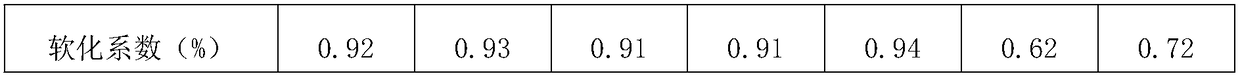

Examples

Embodiment 1

[0030] Prepare a kind of environmentally friendly graphite gypsum board, comprising the following steps:

[0031] (1) Weigh according to the required parts by weight: 30 parts of phosphogypsum powder with a particle size range of 30-100 μm, 60 parts of calcium carbonate powder with a particle size range of 30-70 nm, 12 parts of nano-titanium dioxide, and 12 parts of nano-titanium dioxide as required by national standards. 4 parts of grade I fly ash, 20 parts of expanded graphite with a particle size of 120 mesh, 4 parts of glass fiber, 4 parts of chopped carbon fiber, 14 parts of polyvinyl alcohol, 11 parts of sodium carboxymethyl cellulose, and 90 parts of water.

[0032] (2) Add the titanium dioxide and expanded graphite weighed in step (1) into a two-dimensional motion powder mixer and mix for 10 minutes to obtain the expanded graphite mixture.

[0033] (3) the gypsum powder, calcium carbonate powder, fly ash that step (1) takes by weighing and step (1) take by weighing 50%...

Embodiment 2

[0038] Prepare a kind of environmentally friendly graphite gypsum board, comprising the following steps:

[0039](1) Weigh according to the required parts by weight: 60 parts of desulfurized gypsum powder with a particle size range of 30-100 μm, 120 parts of calcium carbonate powder with a particle size range of 30-70 nm, 30 parts of nano-titanium dioxide, and 30 parts of nano-titanium dioxide as required by national standards. 6 parts of Class II fly ash, 30 parts of expanded graphite with a particle size of 200 mesh, 16 parts of glass fiber, 16 parts of chopped carbon fiber, 16 parts of polyvinyl alcohol, 15 parts of sodium carboxymethyl cellulose, and 180 parts of water.

[0040] (2) Add the titanium dioxide and expanded graphite weighed in step (1) into a three-dimensional motion powder mixer and mix for 30 minutes to obtain the expanded graphite mixture.

[0041] (3) the gypsum powder, calcium carbonate powder, fly ash that step (1) takes by weighing and step (1) take by ...

Embodiment 3

[0046] Prepare a kind of environmentally friendly graphite gypsum board, comprising the following steps:

[0047] (1) Weigh according to the required parts by weight: 40 parts of phosphogypsum powder with a particle size range of 30-100 μm, 70 parts of calcium carbonate powder with a particle size range of 30-70 nm, 15 parts of nano-titanium dioxide, and 15 parts of nano-titanium dioxide as required by national standards. 5 parts of Class II fly ash, 22 parts of expanded graphite with a particle size of 140 mesh, 8 parts of glass fiber, 8 parts of chopped carbon fiber, 15 parts of polyvinyl alcohol, 12 parts of sodium carboxymethyl cellulose, and 100 parts of water.

[0048] (2) Add the titanium dioxide and expanded graphite weighed in step (1) into a double-cone powder mixer and mix for 15 minutes to obtain the expanded graphite mixture.

[0049] (3) the gypsum powder, calcium carbonate powder, fly ash that step (1) takes by weighing and the water that step (1) takes by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com