Total internal reflection color-combination prism and method for producing the same

A technology of total internal reflection and chromatic prism, applied in optical elements, optics, instruments, etc., can solve the problems of difficult manufacturing process of color separation and recombination prism 206, reduced color saturation and contrast, and reduced utilization of light energy, etc. Achieve the effect of improving light energy utilization, avoiding the reduction of color saturation and contrast, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be explained and described in detail below in conjunction with the accompanying drawings.

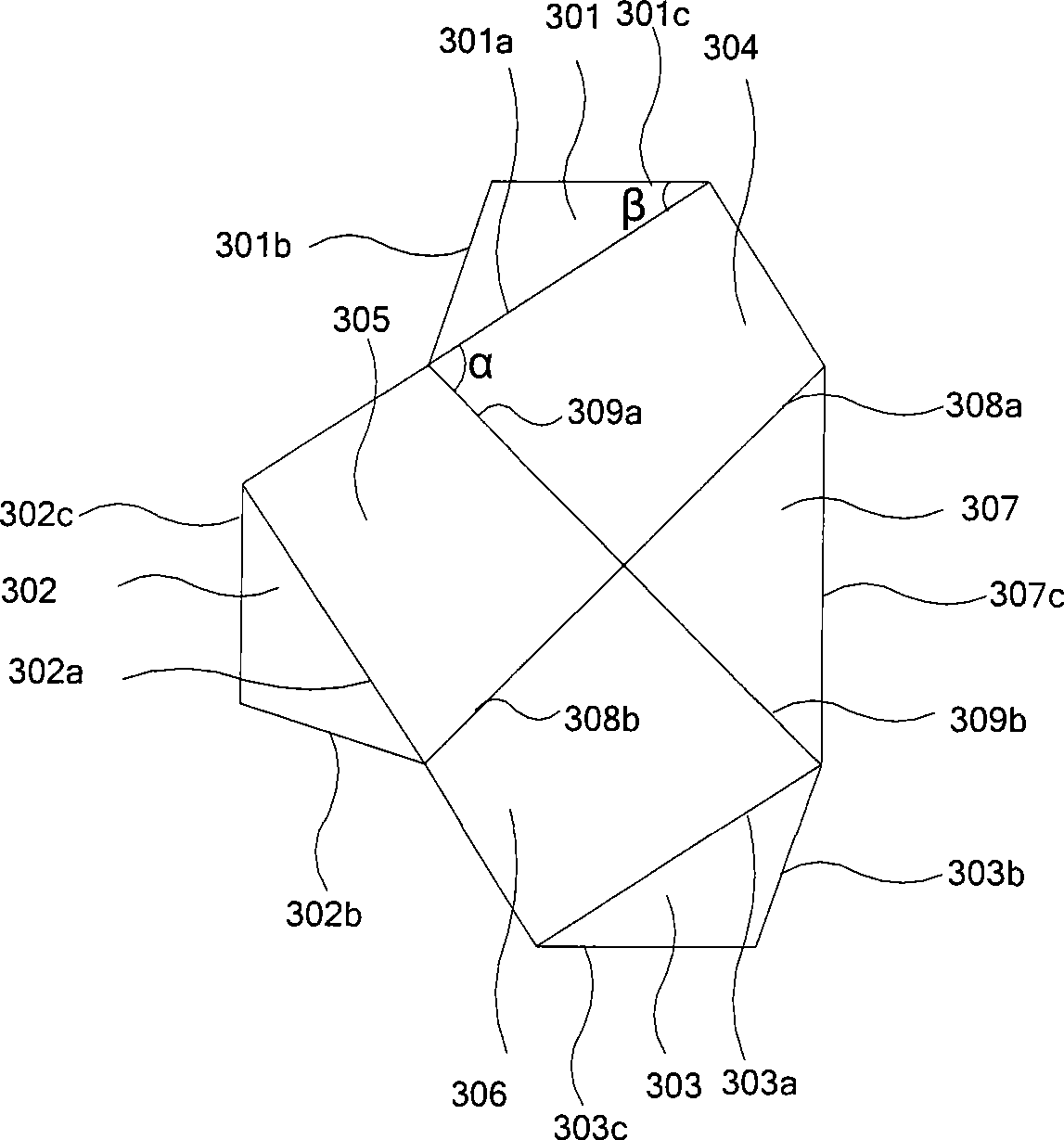

[0053] image 3 It is a structural schematic diagram of a total internal inversion dichroic prism. The total internal inversion dichroic prism is made of seven prisms glued together. Wherein, the first, second and third prisms 301, 302 and 303 are triangular prisms with the same structure, and the angles of the first, second and third prisms 301, 302 and 303 are according to the angle of incident light in the actual design and the DMD The specific conditions are different, wherein the angles of the first, second, and third prisms opposite to the first, second, and third interfaces 301a, 302a, and 303a are usually obtuse angles; the fourth, fifth, and sixth prisms 304, 305 and 306 are quadrangular prisms with the same structure, and at least one angle is a right angle. The 5th and the 6th prism 304,305, two right-angled sides of 306 must be equal, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com