Automatic flaw detection device and method for substrate laser repairing device

A technology of laser repair and defect detection, which is applied in the fields of optics, nonlinear optics, semiconductor/solid-state device testing/measurement, etc., can solve the problems of manpower consumption, reduction, slow speed, etc., save time and trouble, and solve the problem of misjudgment , The effect of low probability of missing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] While the invention will be fully described with reference to the accompanying drawings, which contain preferred embodiments of the invention, it is before proceeding to this description that it is understood that those skilled in the art may modify the invention described herein while still obtaining the benefits of the invention. Therefore, it should be understood that the following description is a broad disclosure for those skilled in the art, and its content is not intended to limit the present invention.

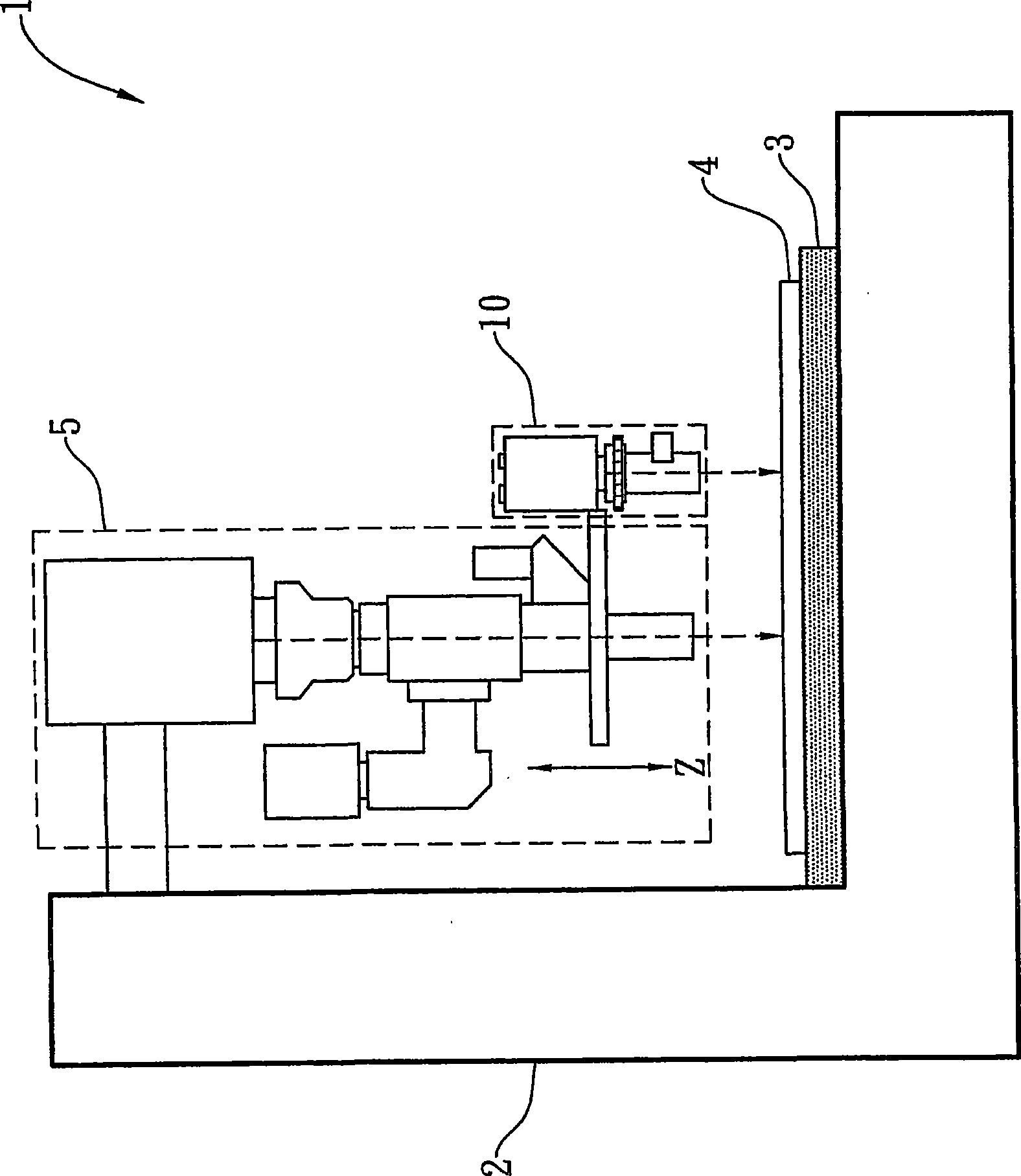

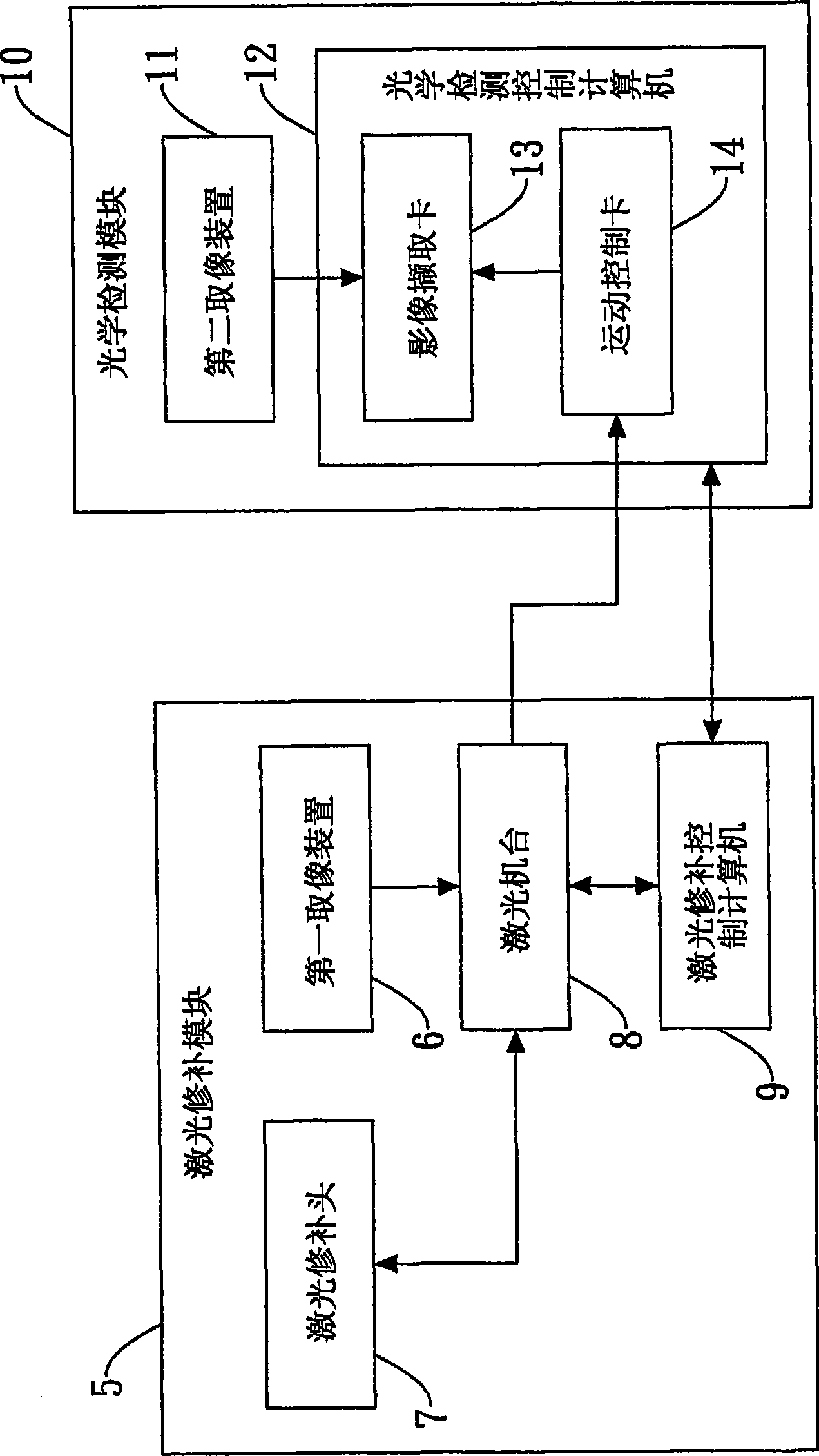

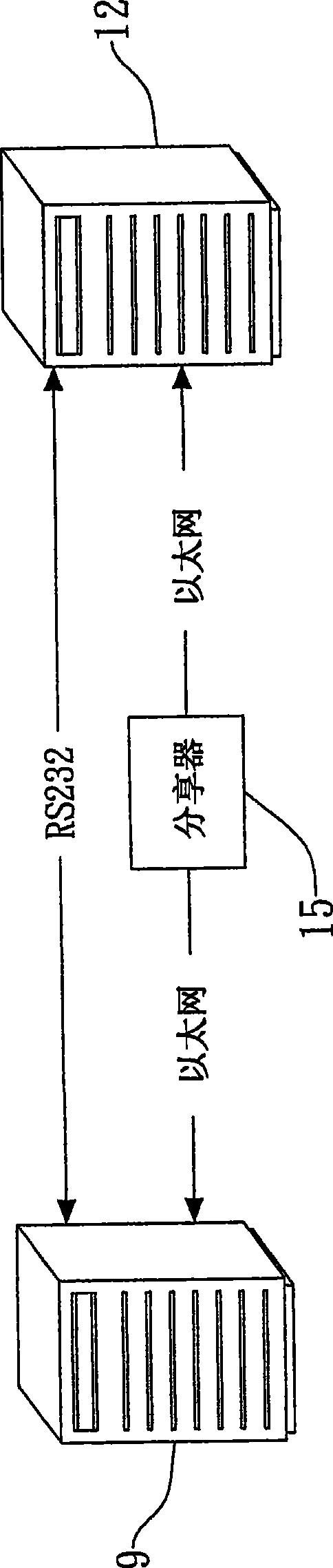

[0048] see figure 1 and figure 2 A schematic diagram and a block diagram of the automatic defect detection device 1 of the substrate laser repairing machine of the present invention are shown respectively. The automatic defect detection device 1 of the substrate laser repairing machine of the present invention comprises a machine base 2; a substrate carrying platform 3 set on the machine base 2; a substrate 4 carried on the substrate supporting platform 3; a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com