Energy-saving automatic lifting type downwind plate of wagon

A tailwind, lift-type technology, applied in the direction of the body, vehicle parts, streamlined body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

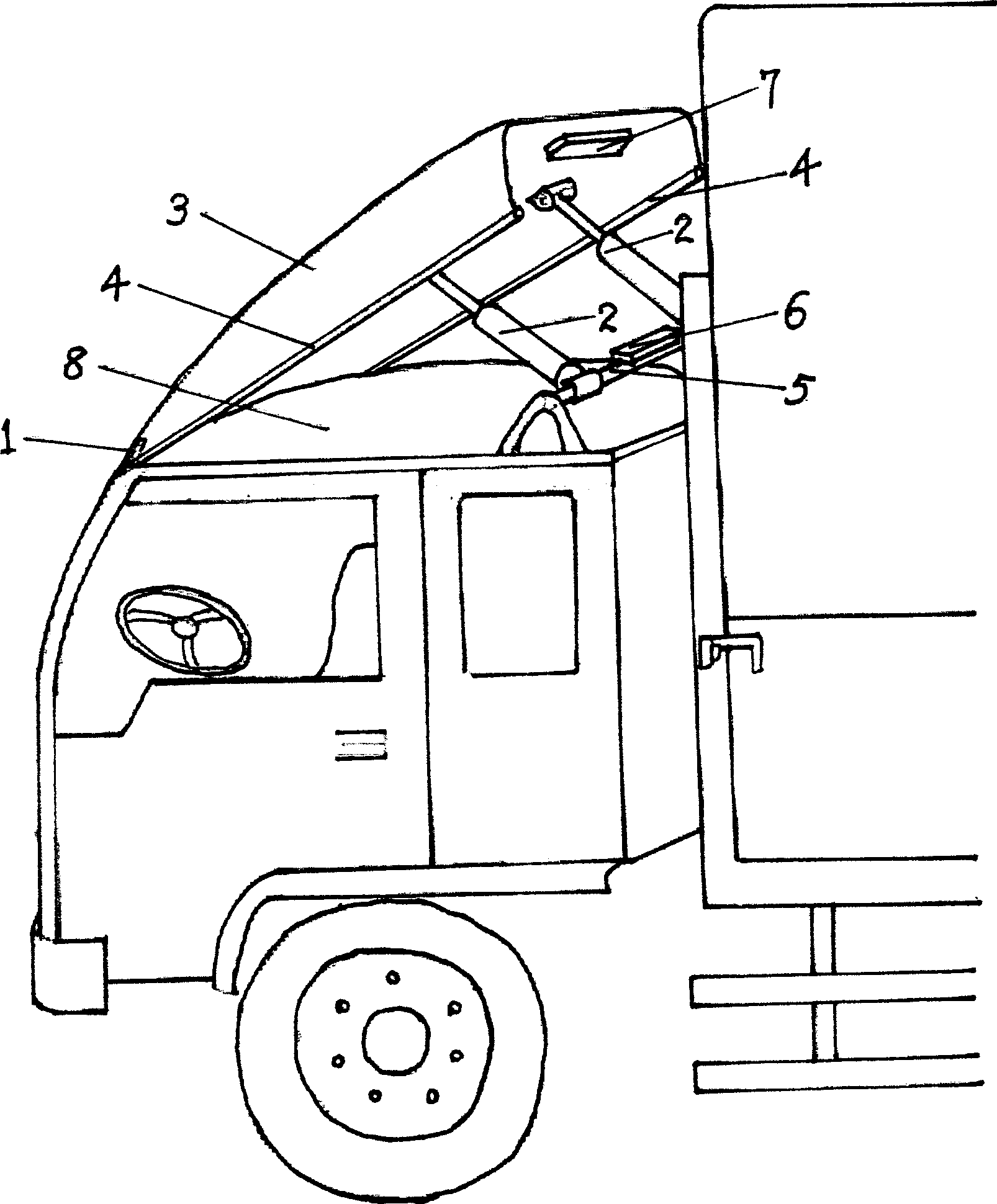

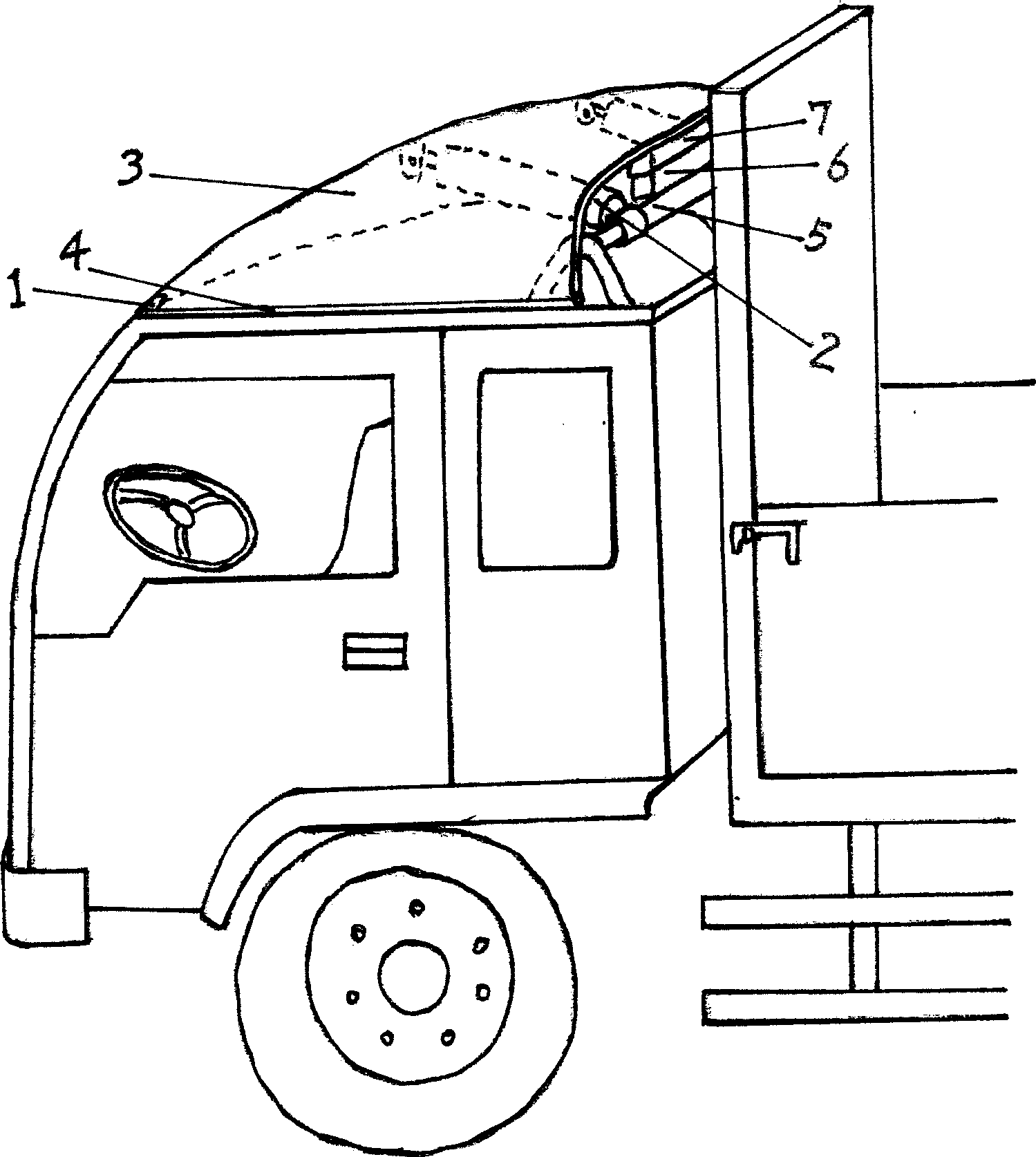

[0010] exist figure 1 The middle hinge (1) is installed in front of the cab (8) loam cake, the other side of the hinge (1) is connected with the front part of the downwind board (3), and the upper end of the cylinder (2) is pushed against the downwind board (3). ) at the lower end of the rear and form a rotational connection. The lower end of the cylinder (2) is installed on one end of the cross bar (5) and also forms a rotational connection. The two ends of the cross bar (5) are respectively fixedly installed on the two ends of the cab (8) upper cover, the middle part of the cross bar (5) is equipped with an electromagnet (6), and the corresponding downwind plate (3) is equipped with Iron block (7), hollow rubber strip (4) is equipped with respectively on both sides of downwind board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com