Large-sized thruster underwater installing process based on L type floating platform

A floating platform and installation process technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of inaccurate positioning, difficulty in precise positioning and safe installation of thrusters, etc., achieve simple operation process, reduce intermediate waiting and preparation Time, sealing convenient and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

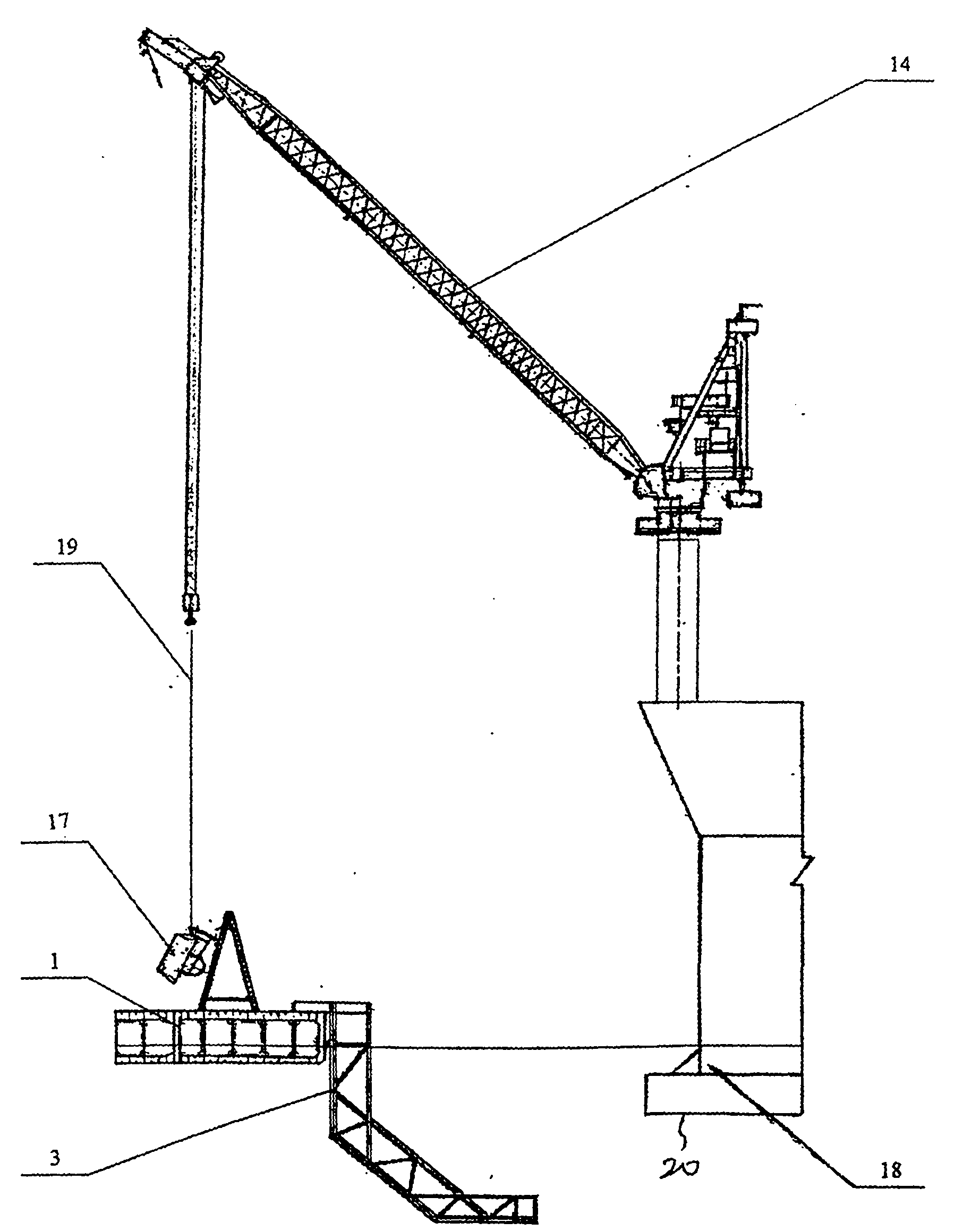

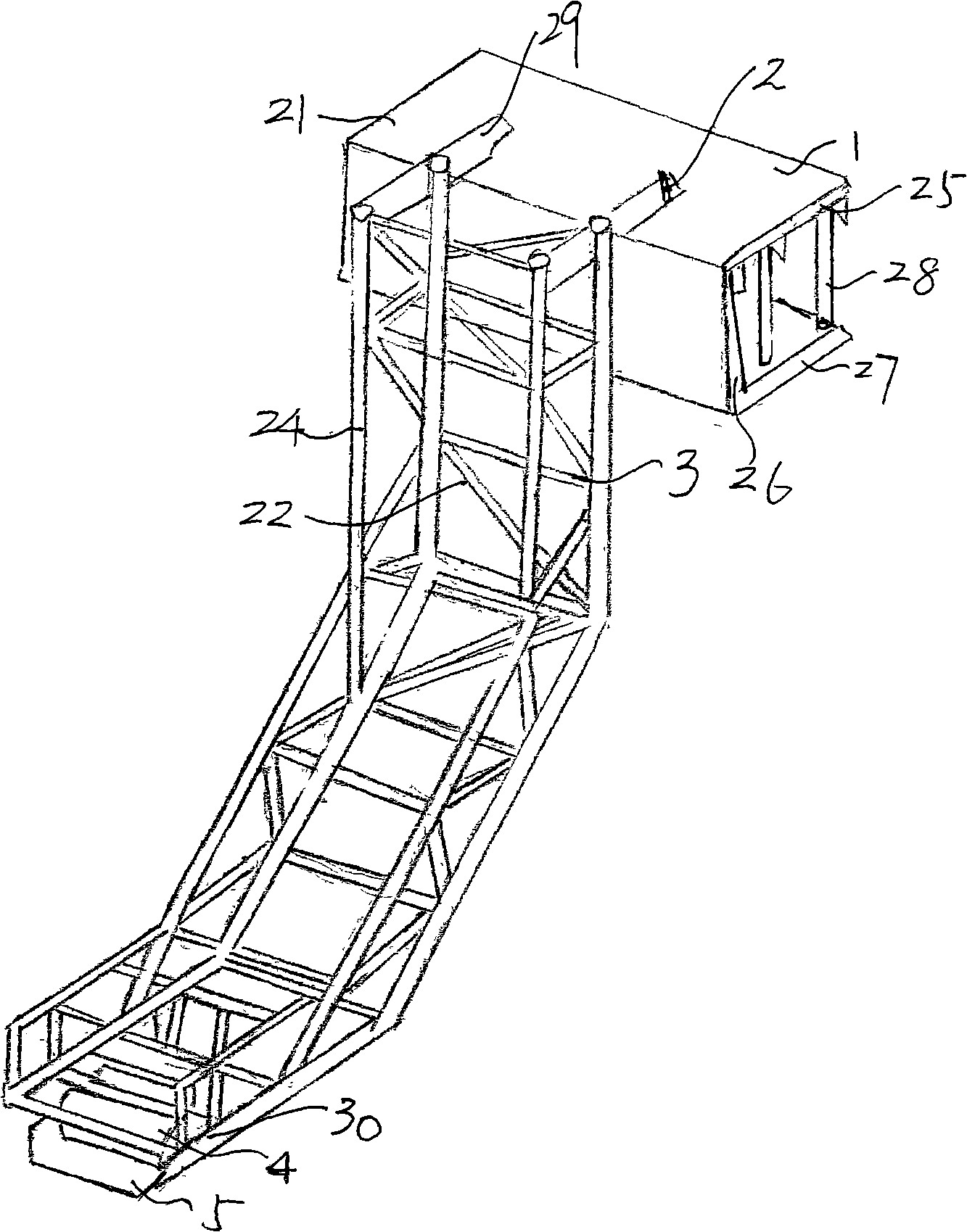

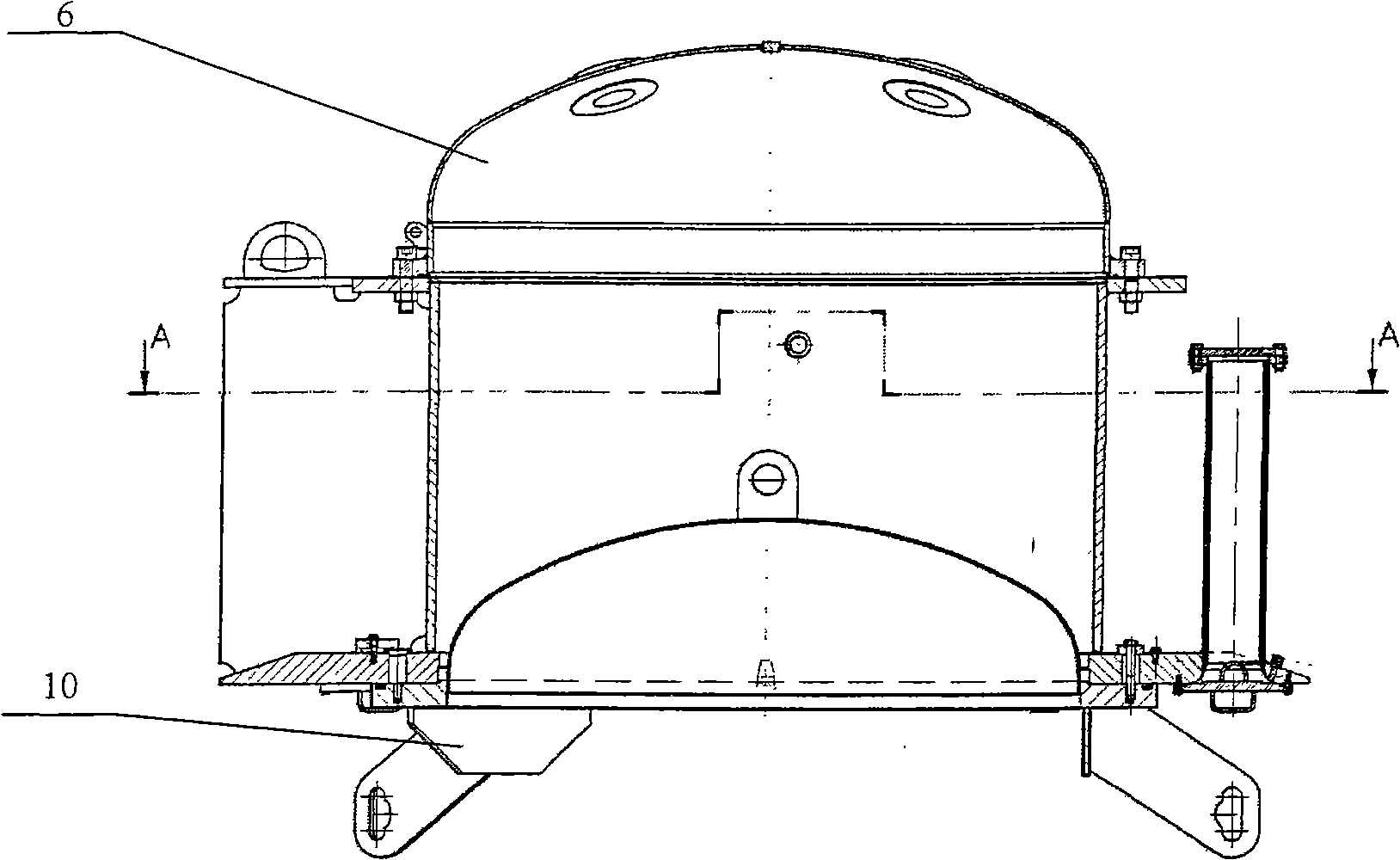

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is illustrated by the propeller installation of the SEVAN 650 cylindrical offshore drilling oil storage platform. The whole process includes the construction of the L-shaped floating platform, the removal of the cover of the propeller installation port on the bottom of the ship, the hoisting and launching of the propeller, the displacement of the propeller, Positioning and installation, the construction of the L-shaped floating platform includes the test of launching conditions, the construction of the L-shaped bracket, the connection and fixation of the propeller placement plate and the adjustment mechanism, the connection and fixation of the floating platform and the L-shaped bracket, and the propeller on the L-shaped floating platform. The placement on the deck, the process of removing the cover of the installation por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com